The document provides details about Vipin Kumar's training at Diesel Locomotive Works (DLW) in Varanasi, Uttar Pradesh. It includes:

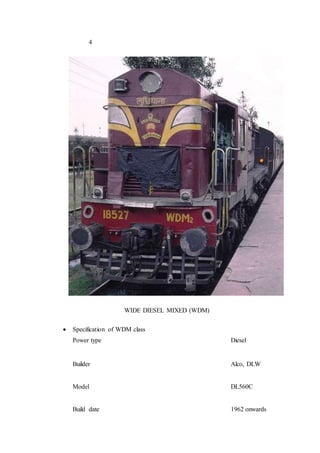

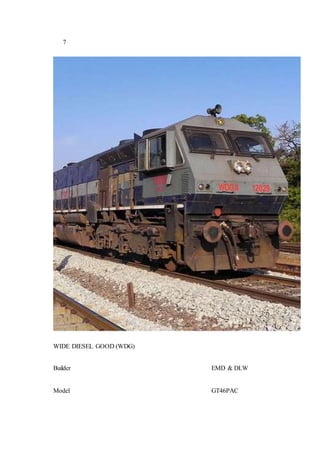

1) An introduction to DLW, which was established in 1956 and manufactures diesel-electric locomotives for Indian Railways. It produces locomotives of various types including WDM, WDP, WDG, and WDS.

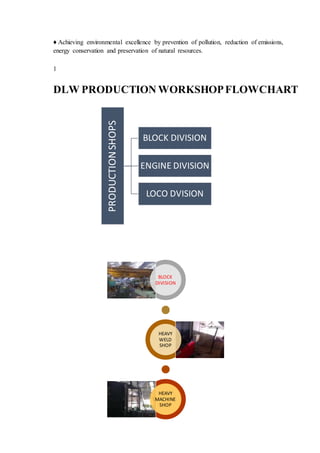

2) Descriptions of sections within DLW such as welding, machining, painting, and assembly shops where locomotive production takes place.

3) Acknowledgements from the author thanking DLW and his college for enabling the training opportunity.

4) Tables of contents and preface describing