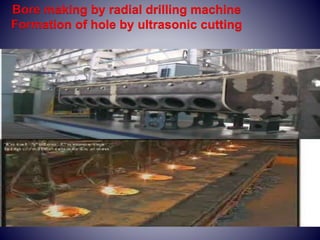

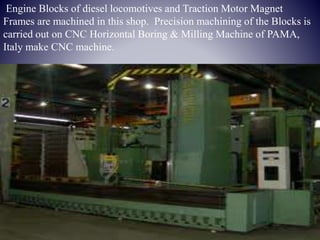

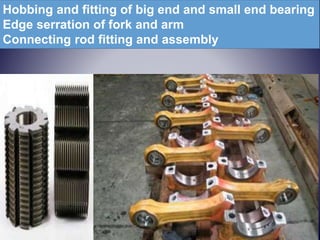

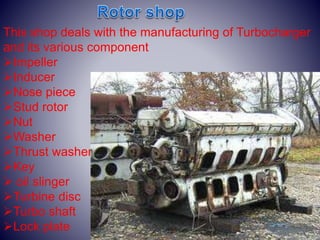

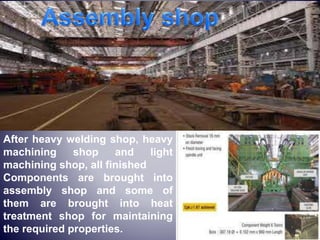

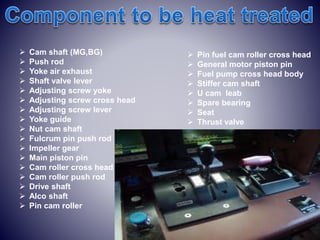

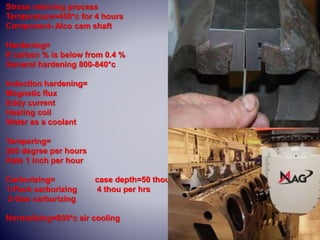

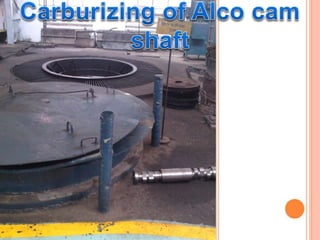

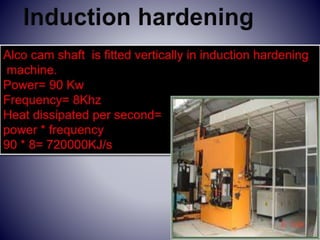

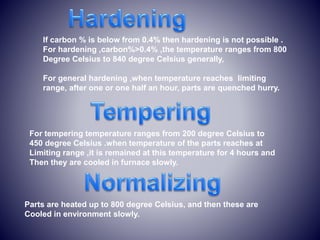

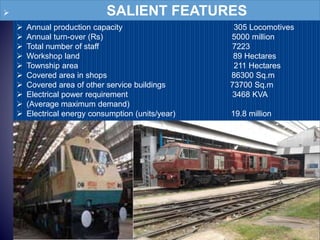

The document provides an overview of the DLW workshop in Varanasi, India. It discusses the history and facilities of DLW, which was established in 1961 to manufacture diesel-electric locomotives. It details the various shops in the workshop, including heavy machine shop, light machine shop, rotor shop, and heat treatment shop. It provides examples of components machined and processes performed in each shop, such as crankcase machining, connecting rod assembly, and heat treatments like induction hardening.

![NOMENCLATURE OF LOCOMOTIVE

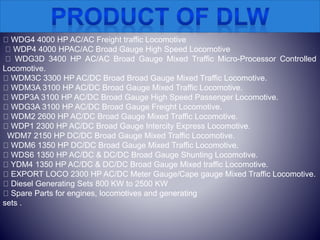

The code is of the form

[gauge][power][load][series][suffix]

GAUGE-

W(BROAD)

Y (METRE)

Z (NARROW,2.6’)

N (NARROW,2’)

POWER-

D = Diesel

C = DC traction

A = AC traction

CA = Dual-power AC/DC

B = Battery electric (rare)

LOAD-

P=passenger

G=goods

M=mixed both AC and DC

SERIES

3=3000HP

4=4000HP

5=5000HP

SUFFIX

A=100HP

B=200HP

C=300HP

D=400HP](https://image.slidesharecdn.com/rohitpresentation1-140809230221-phpapp02/85/ROHIT-KUMAR-BHARDWAJ-MADHUBAN-MAU-7-320.jpg)