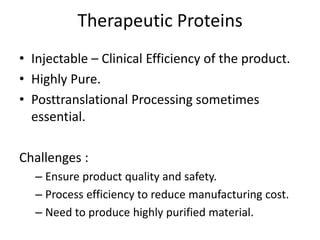

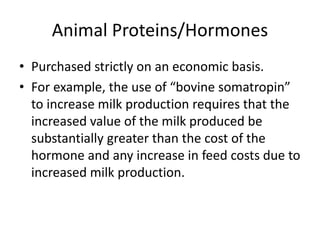

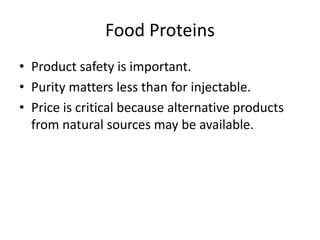

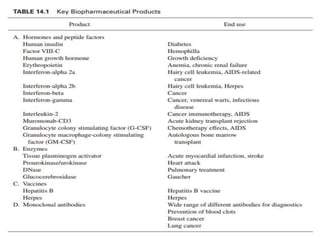

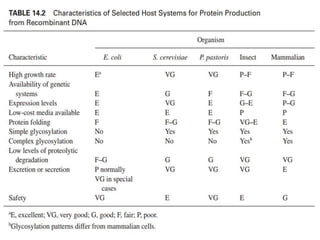

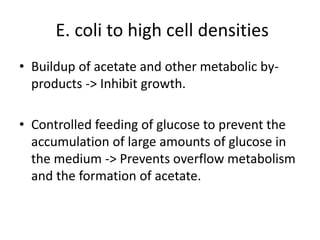

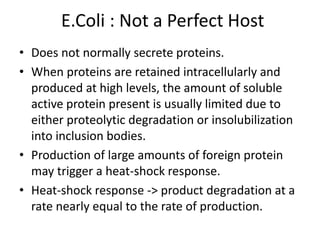

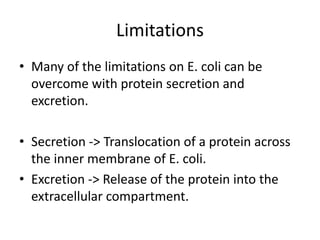

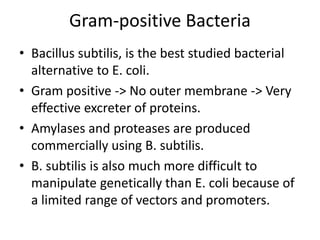

This document discusses different host vector systems for producing recombinant proteins and nonproteins through genetically engineered organisms. It provides guidelines for choosing host-vector systems, noting that the choice depends on factors like whether the product requires posttranslational modifications, its intended use, and characteristics of the host like E. coli and B. subtilis. E. coli is widely used but has limitations like inclusion body formation; secretion and excretion strategies can overcome some limitations. The document compares pros and cons of different systems for therapeutic, food, and industrial applications.