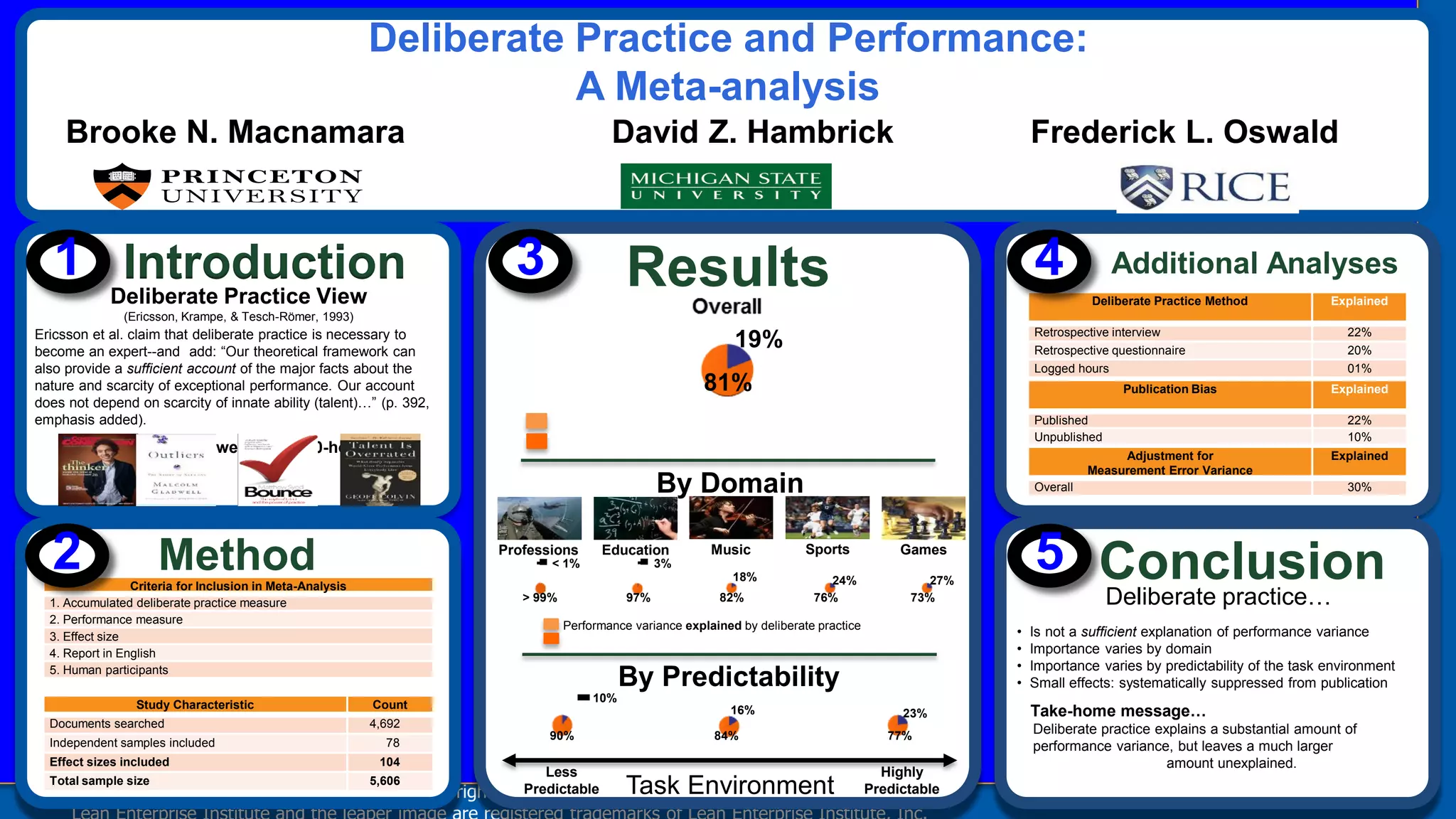

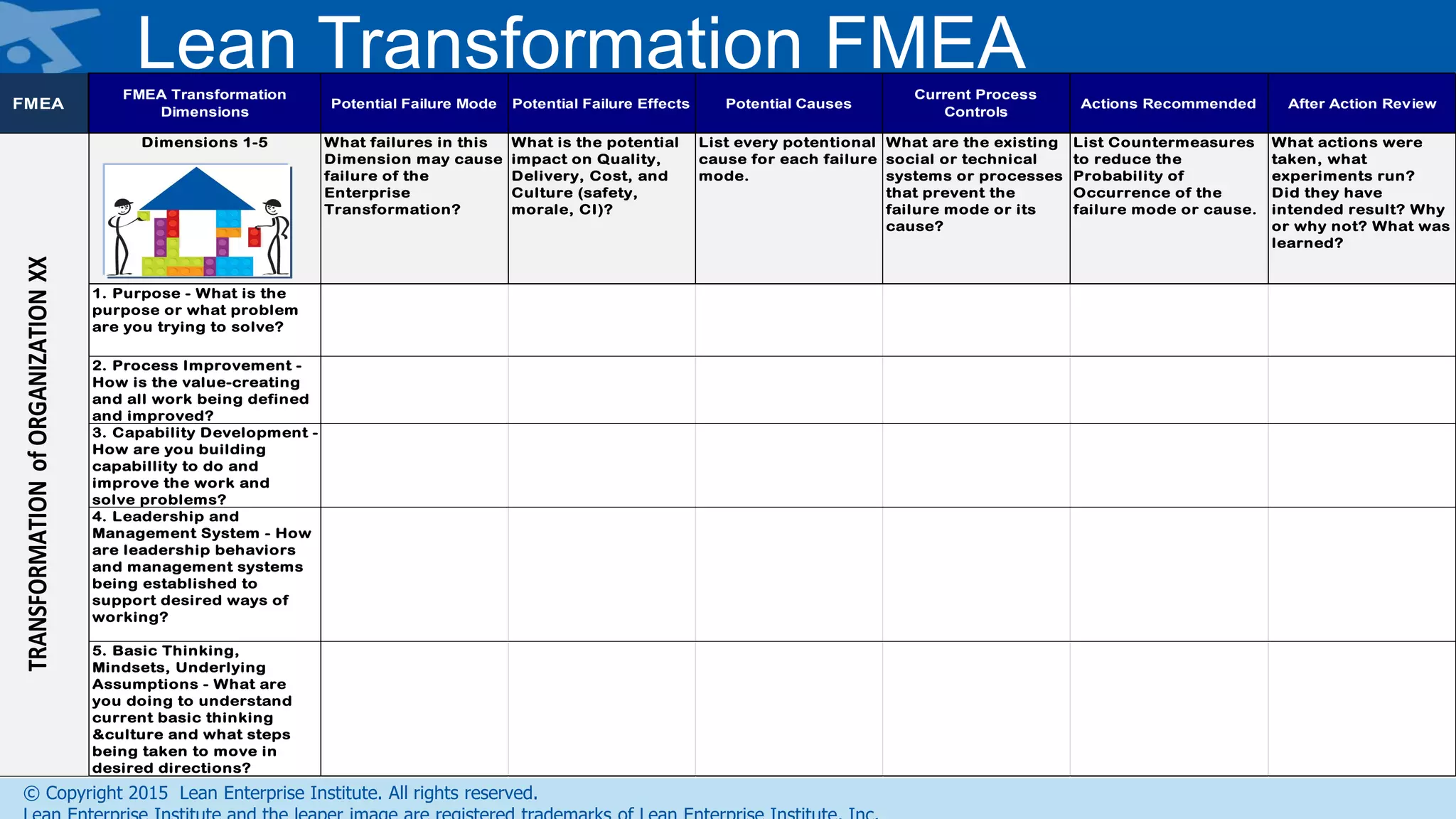

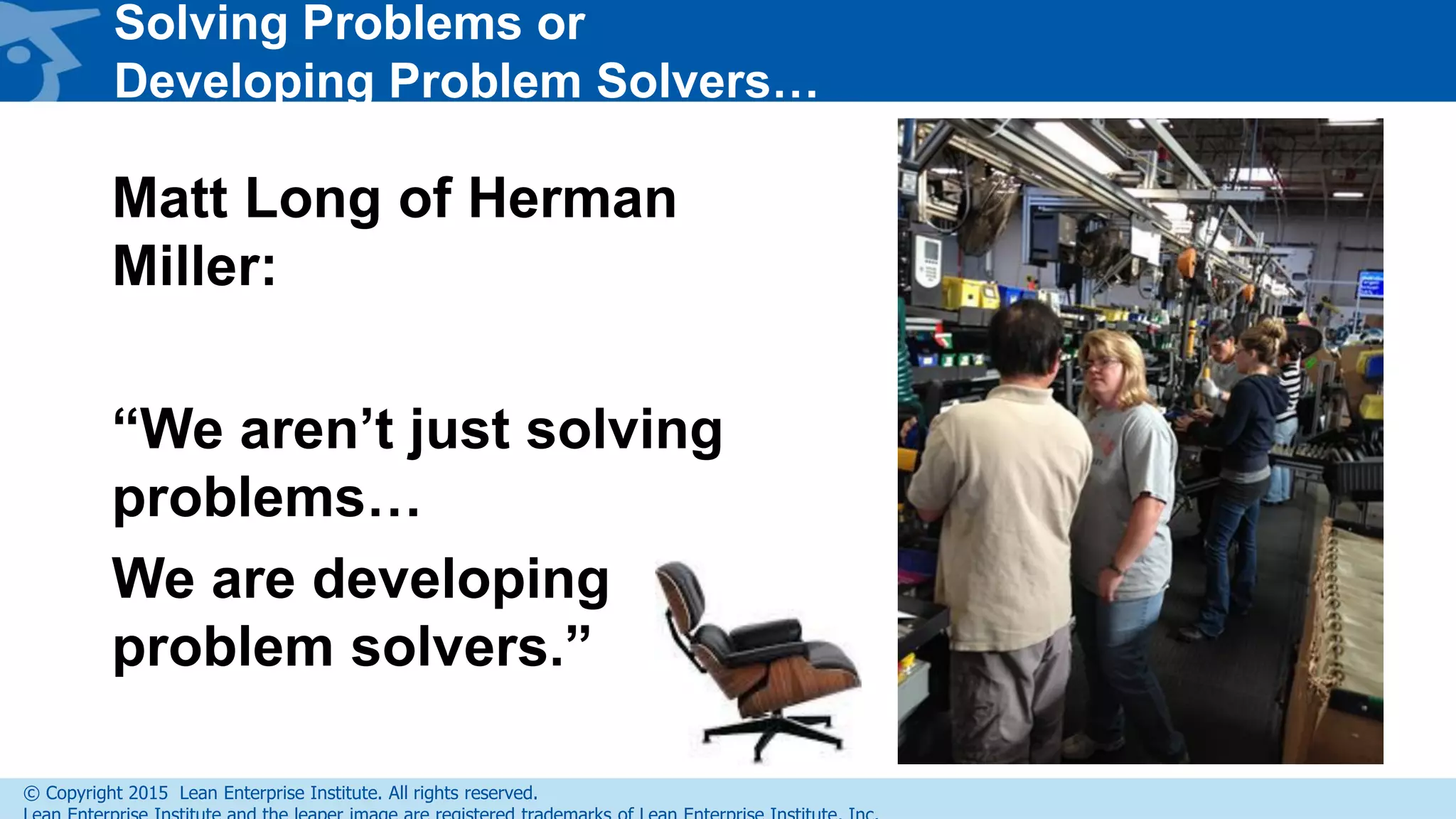

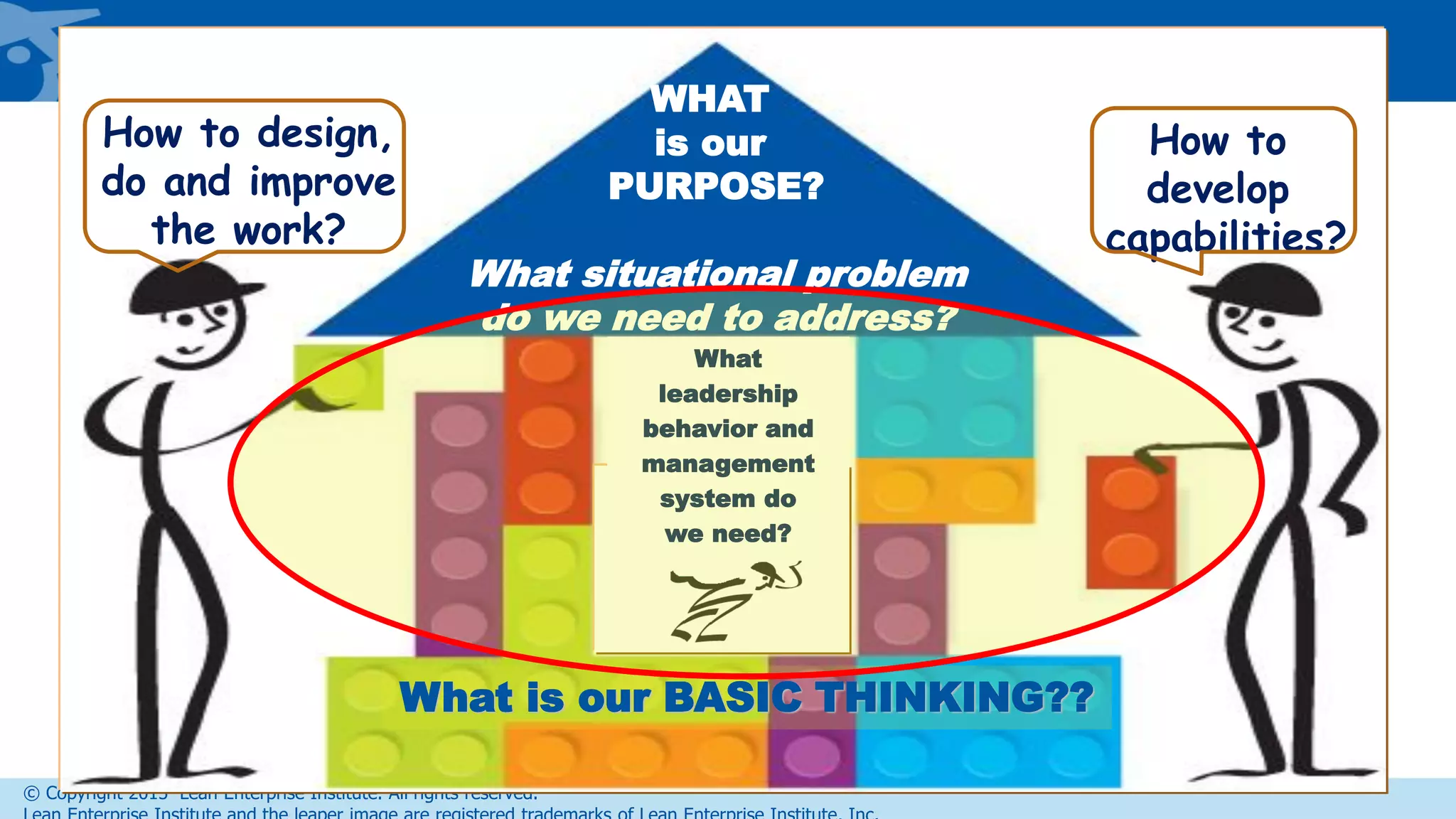

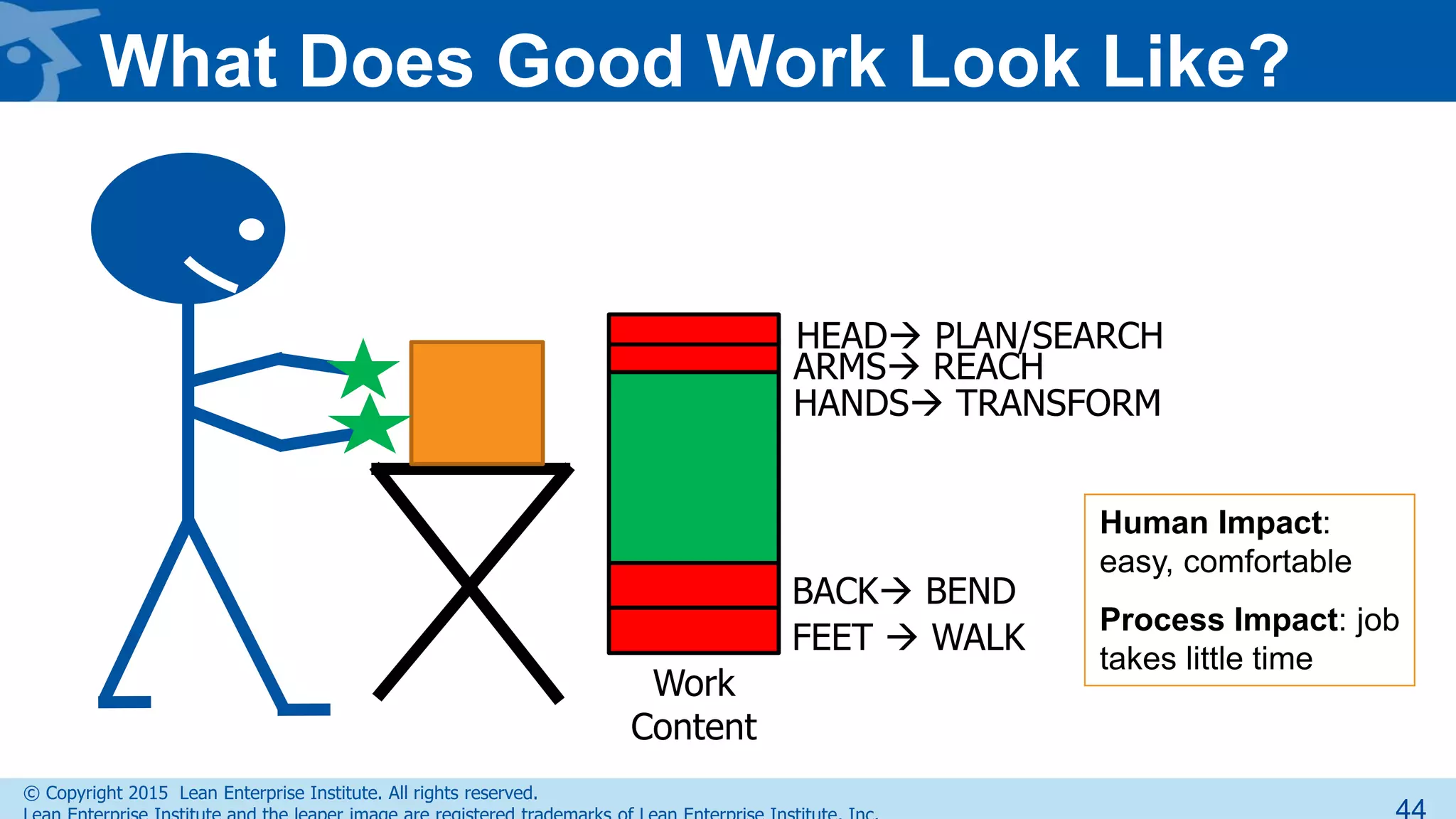

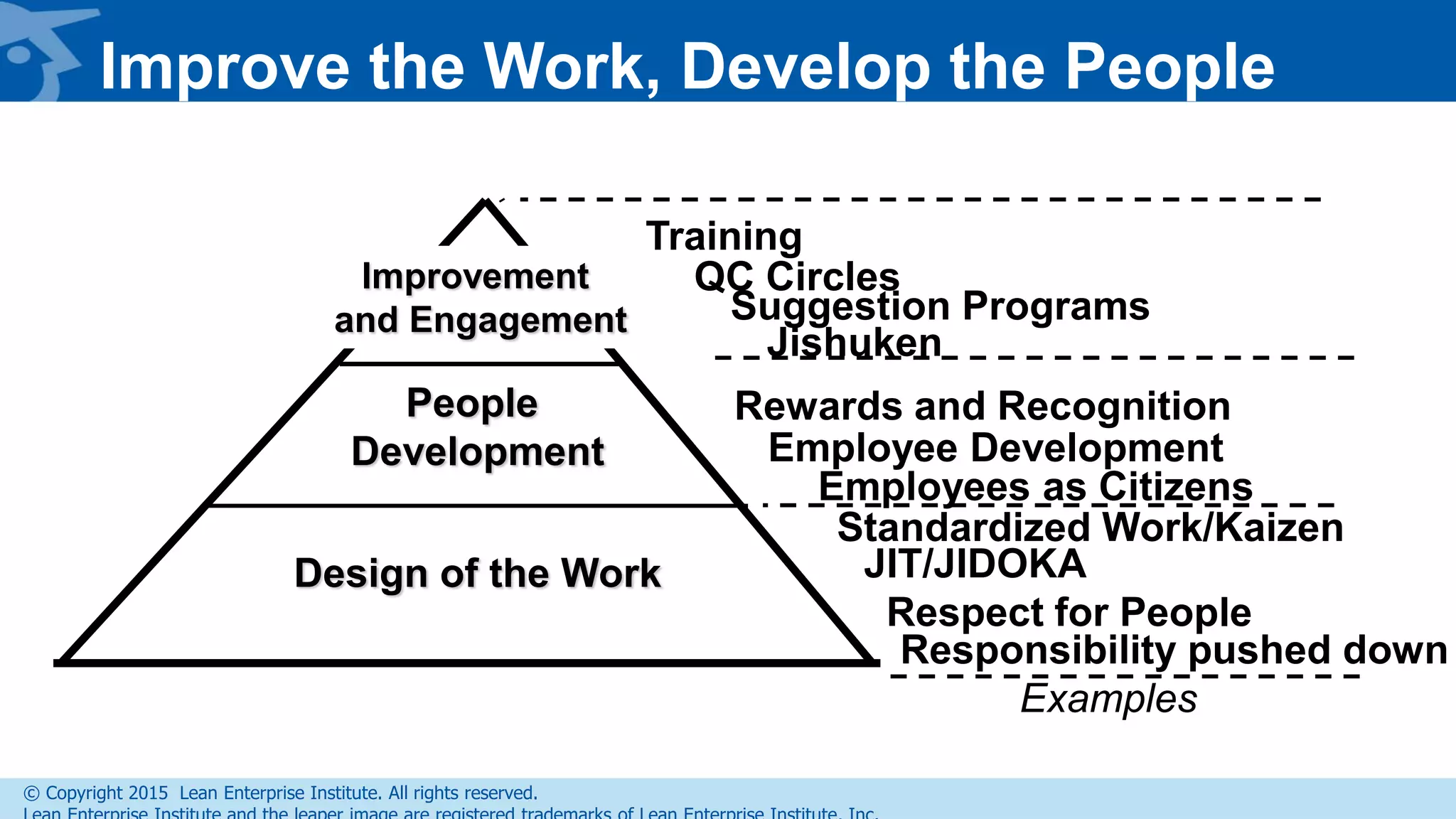

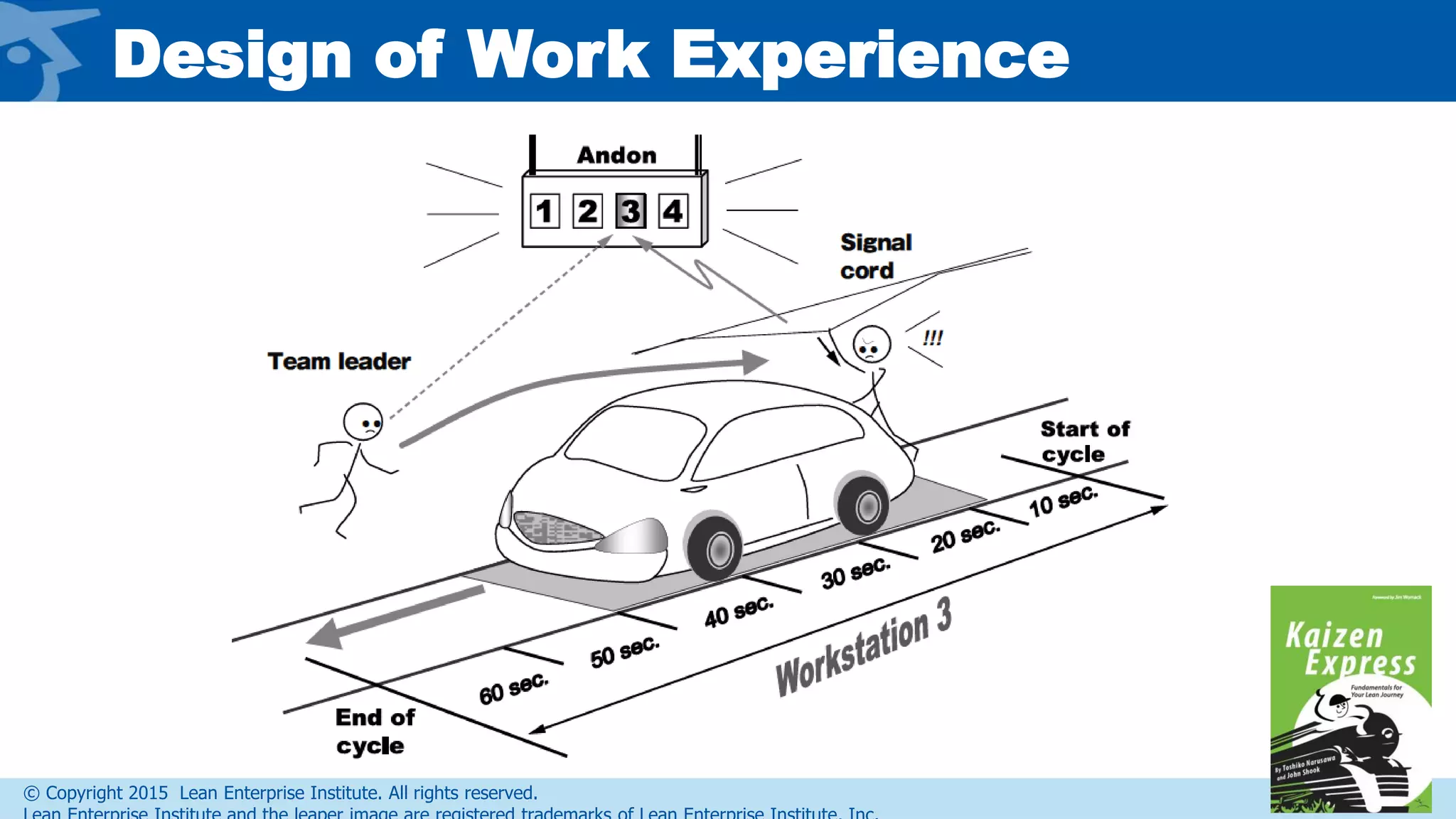

The document discusses the concept of 'lean by doing,' emphasizing the importance of deliberate practices in learning and problem-solving within organizations. It highlights how creating an environment that fosters continuous learning and engagement among workers can lead to overall improvement in work processes. Additionally, it stresses that successful lean transformation requires addressing specific challenges related to purpose, process design, capability development, and leadership behavior.