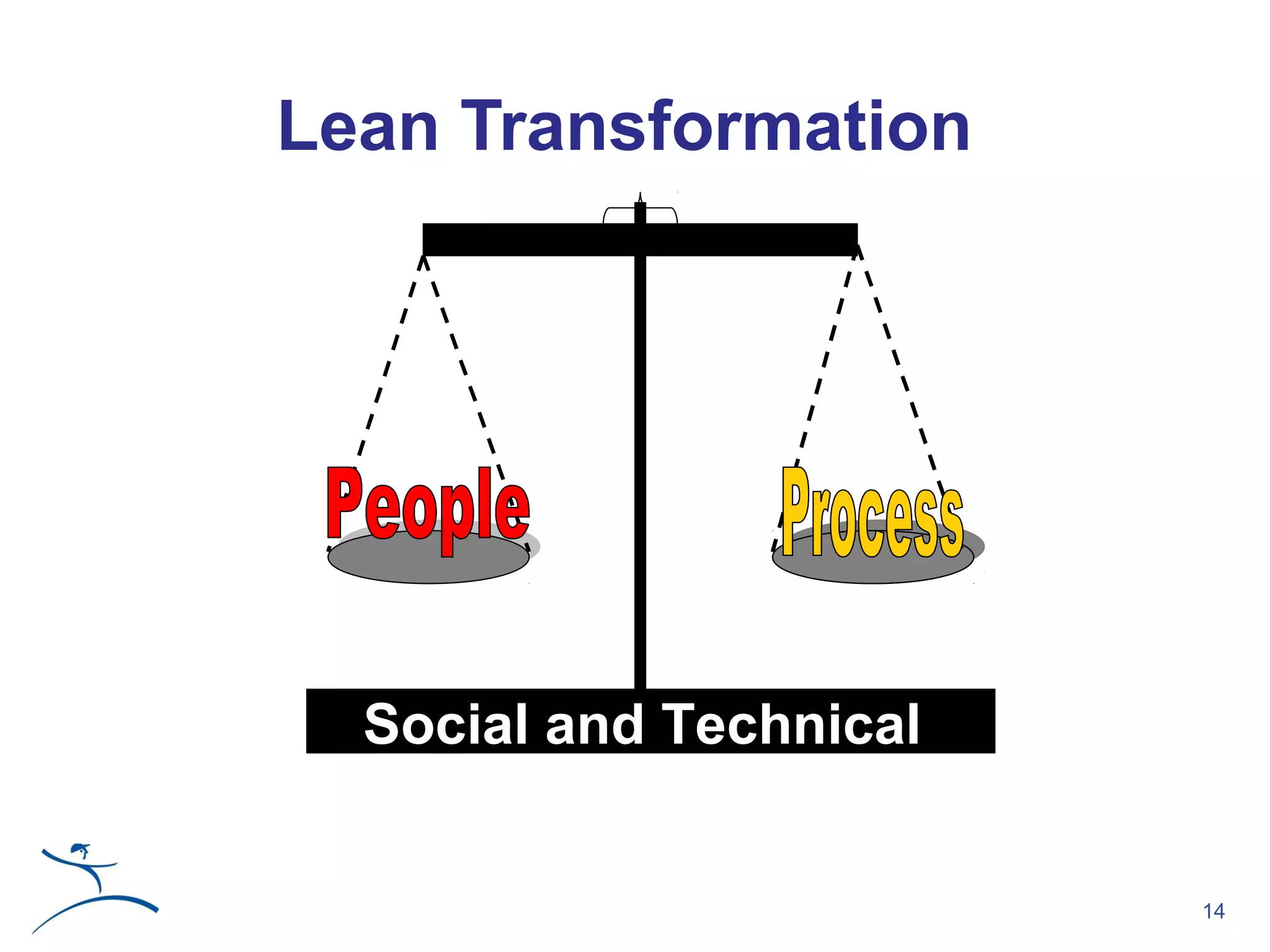

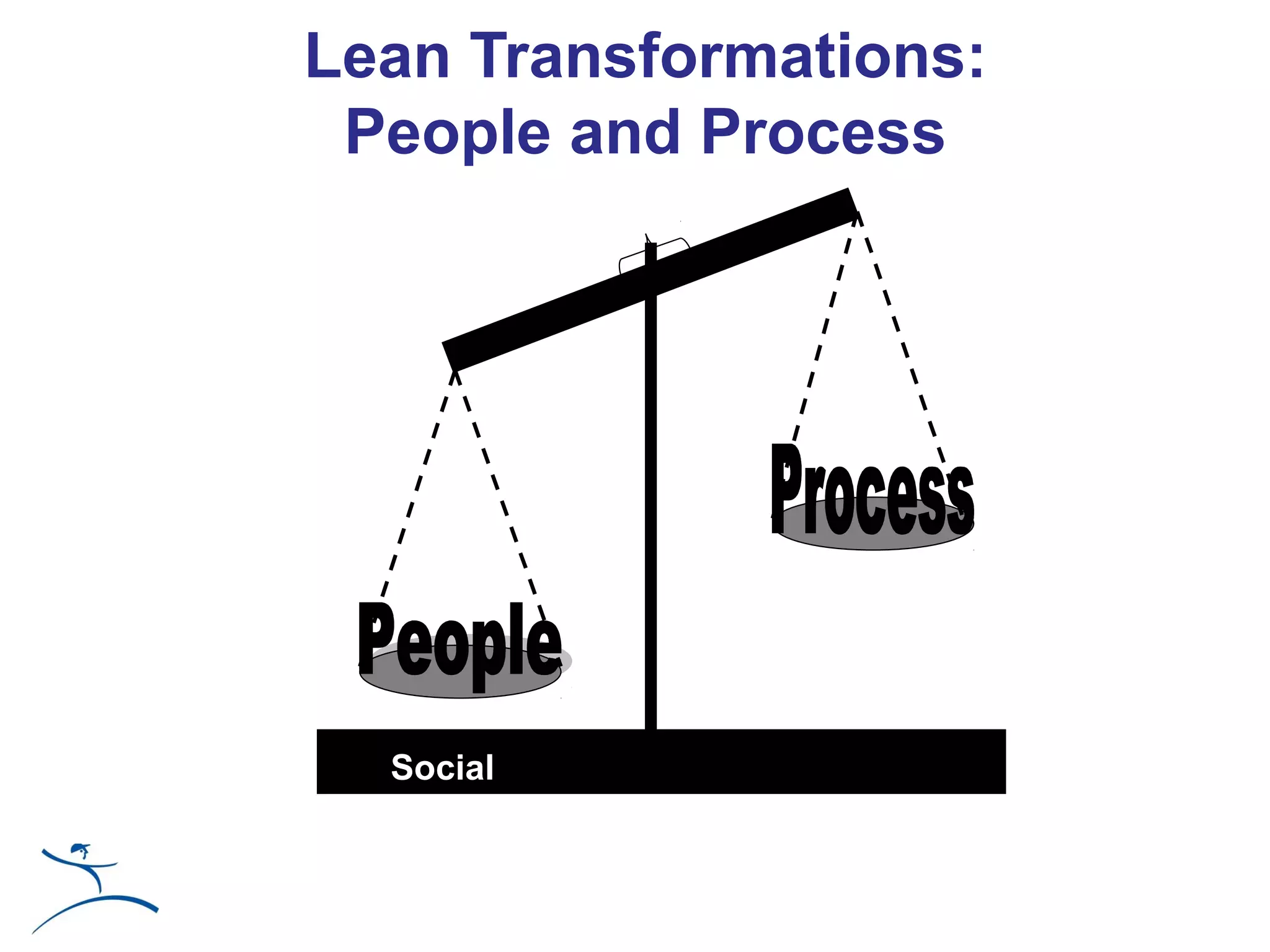

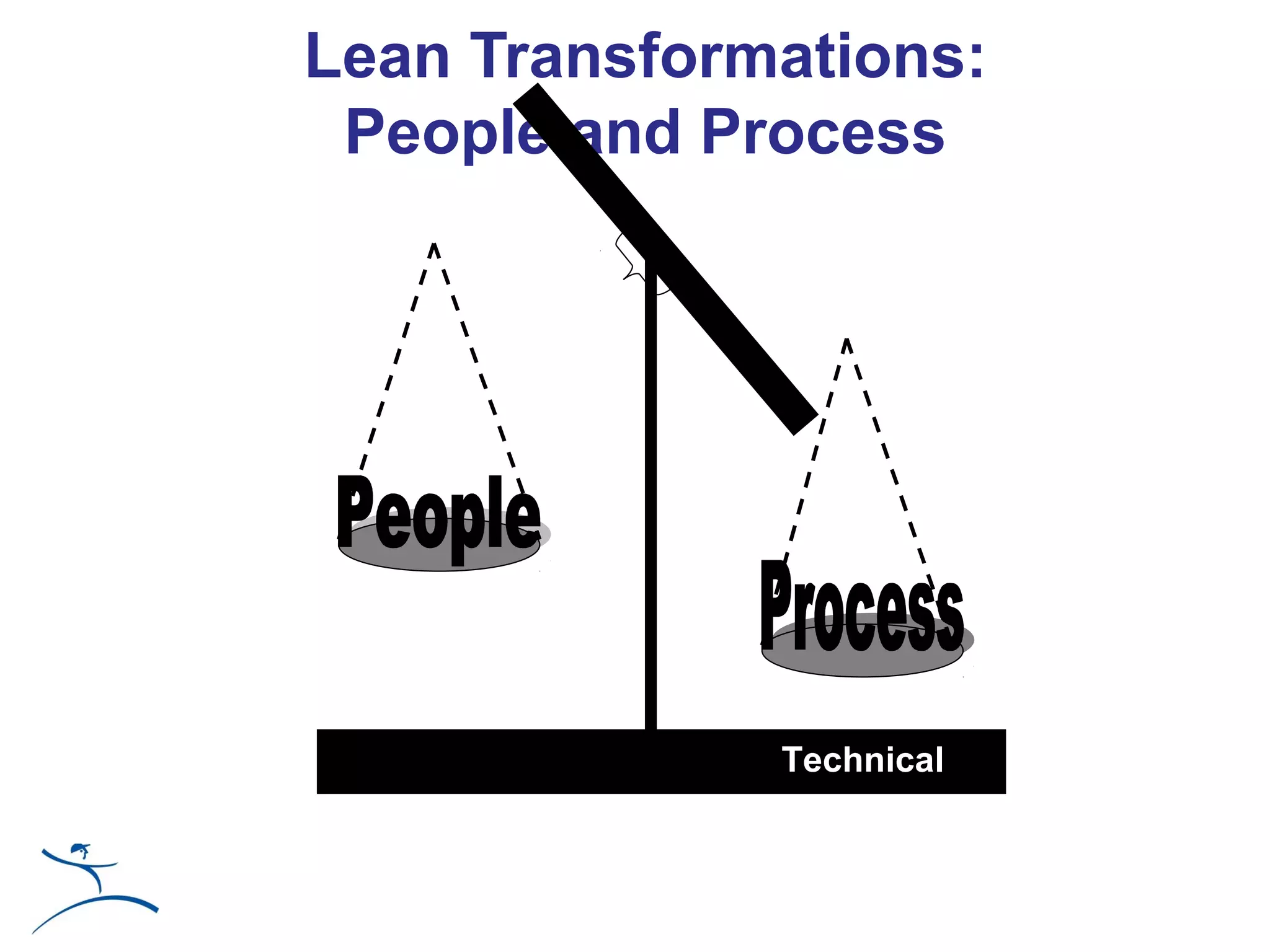

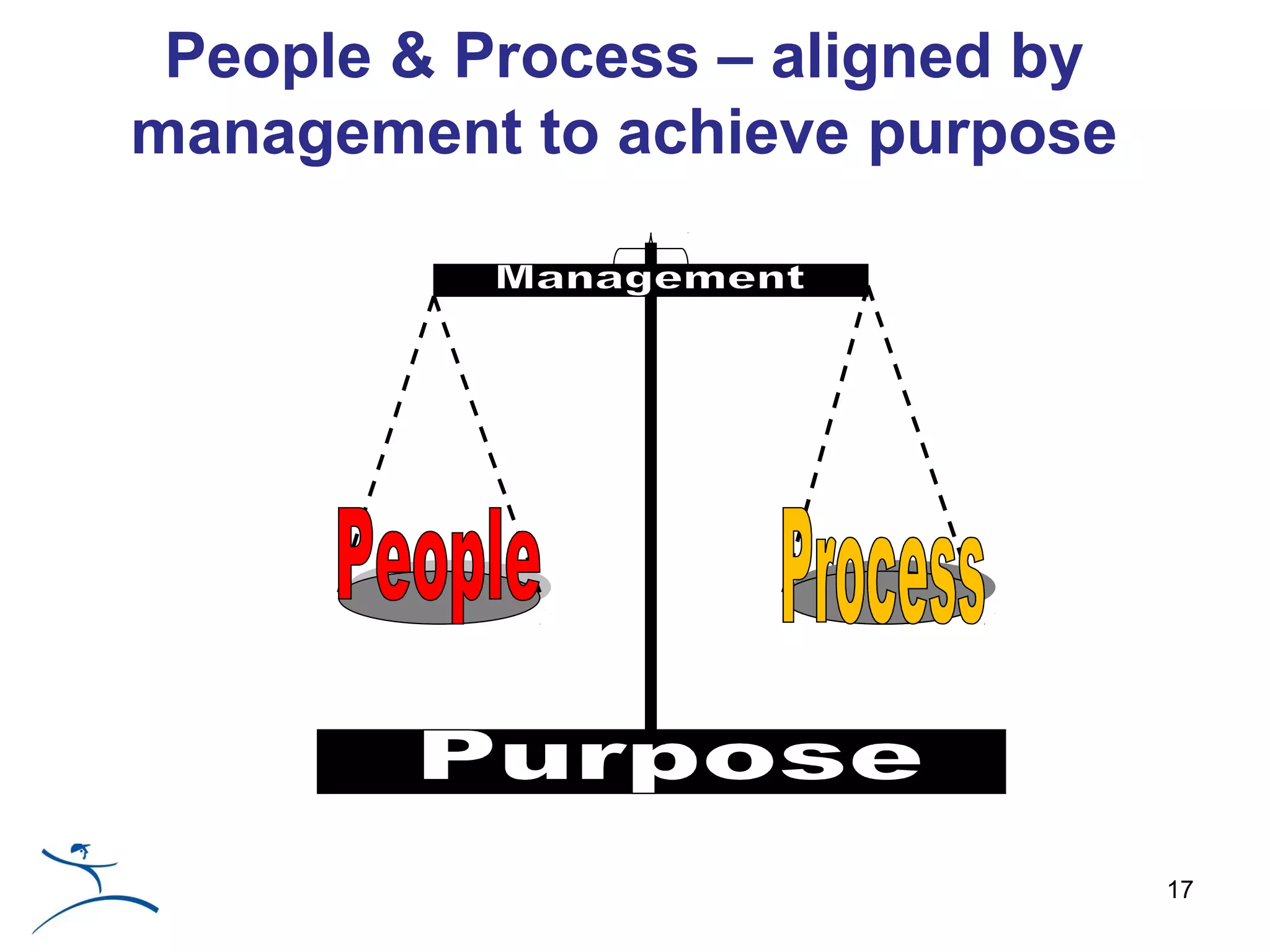

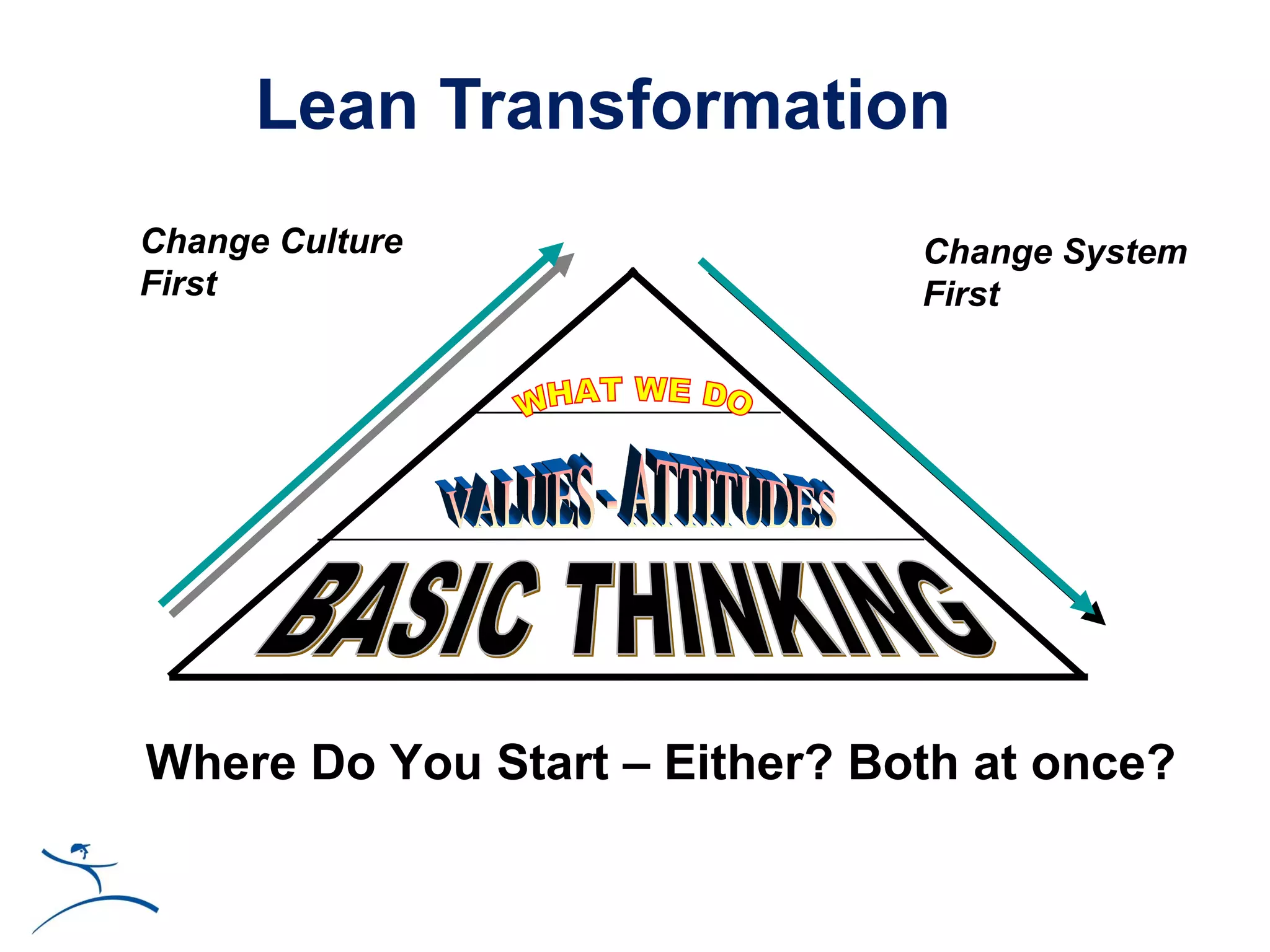

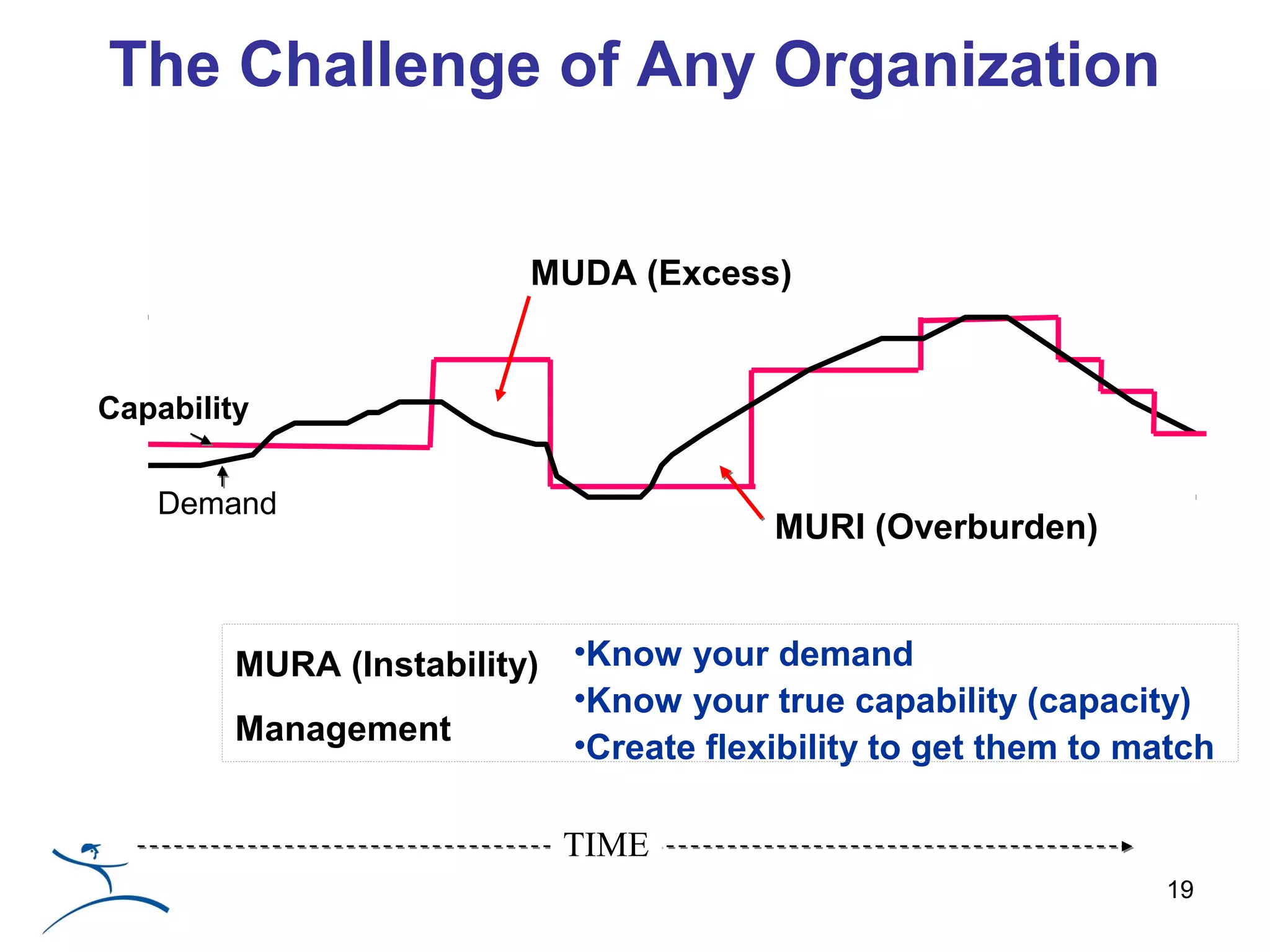

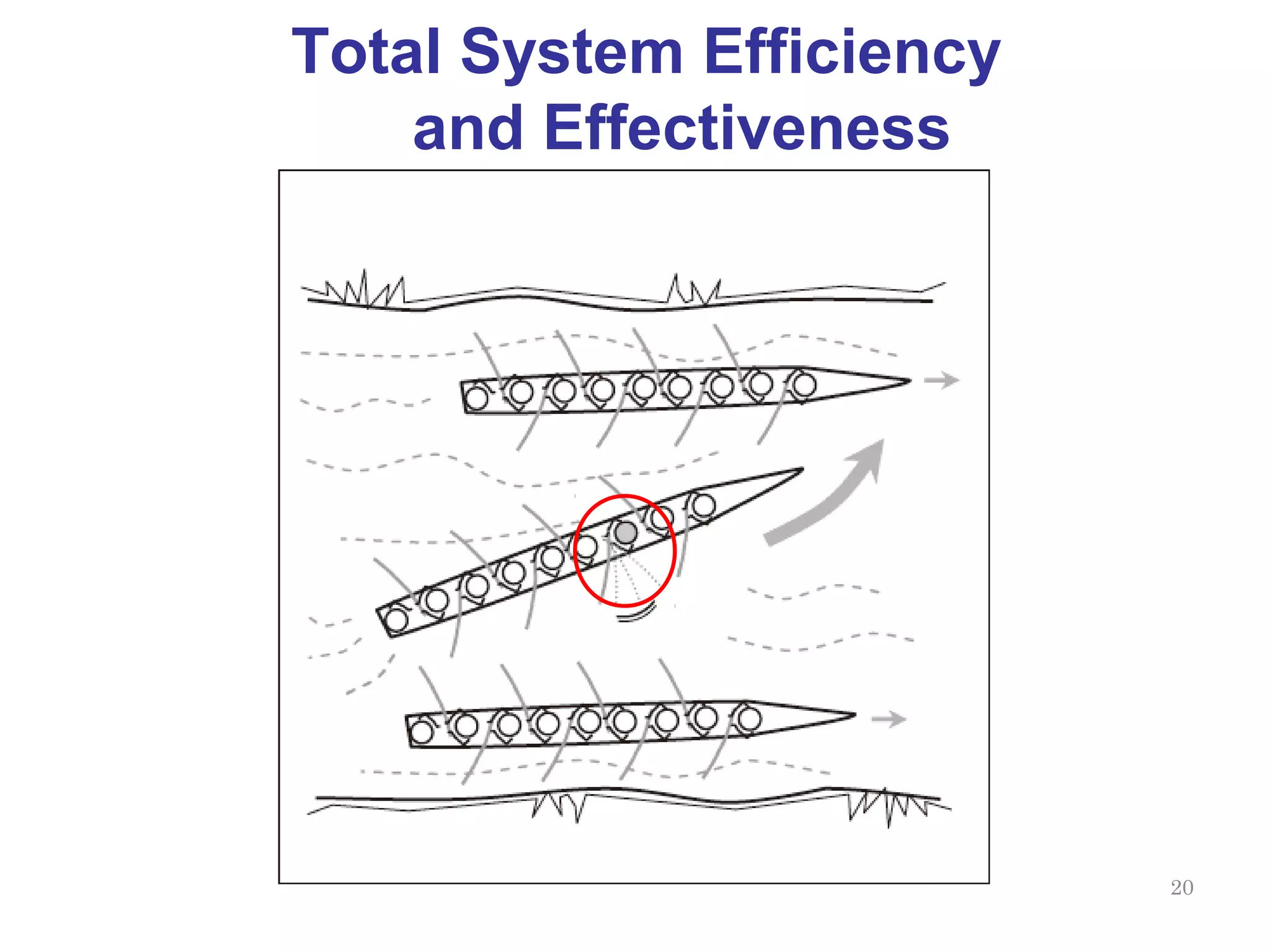

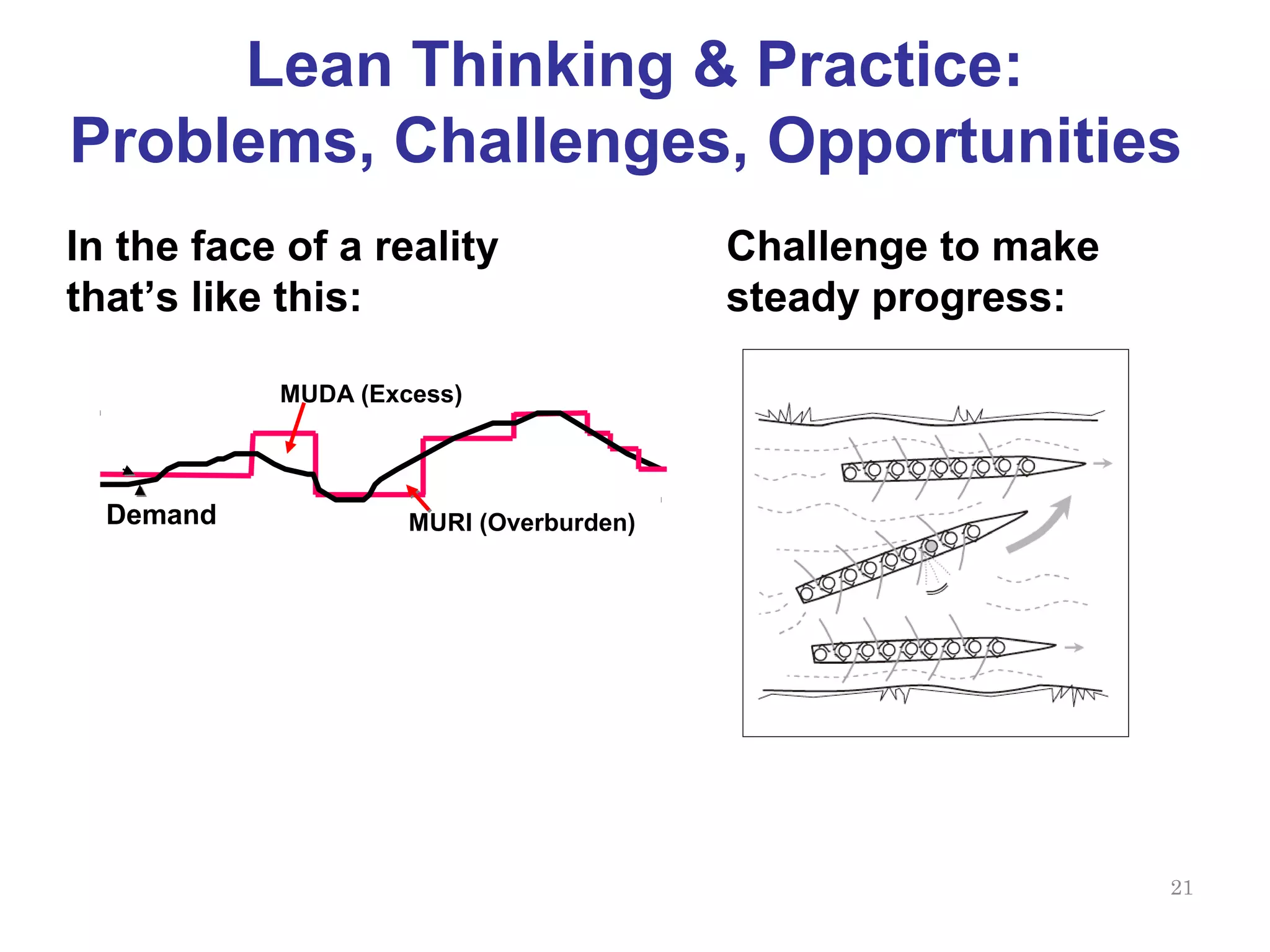

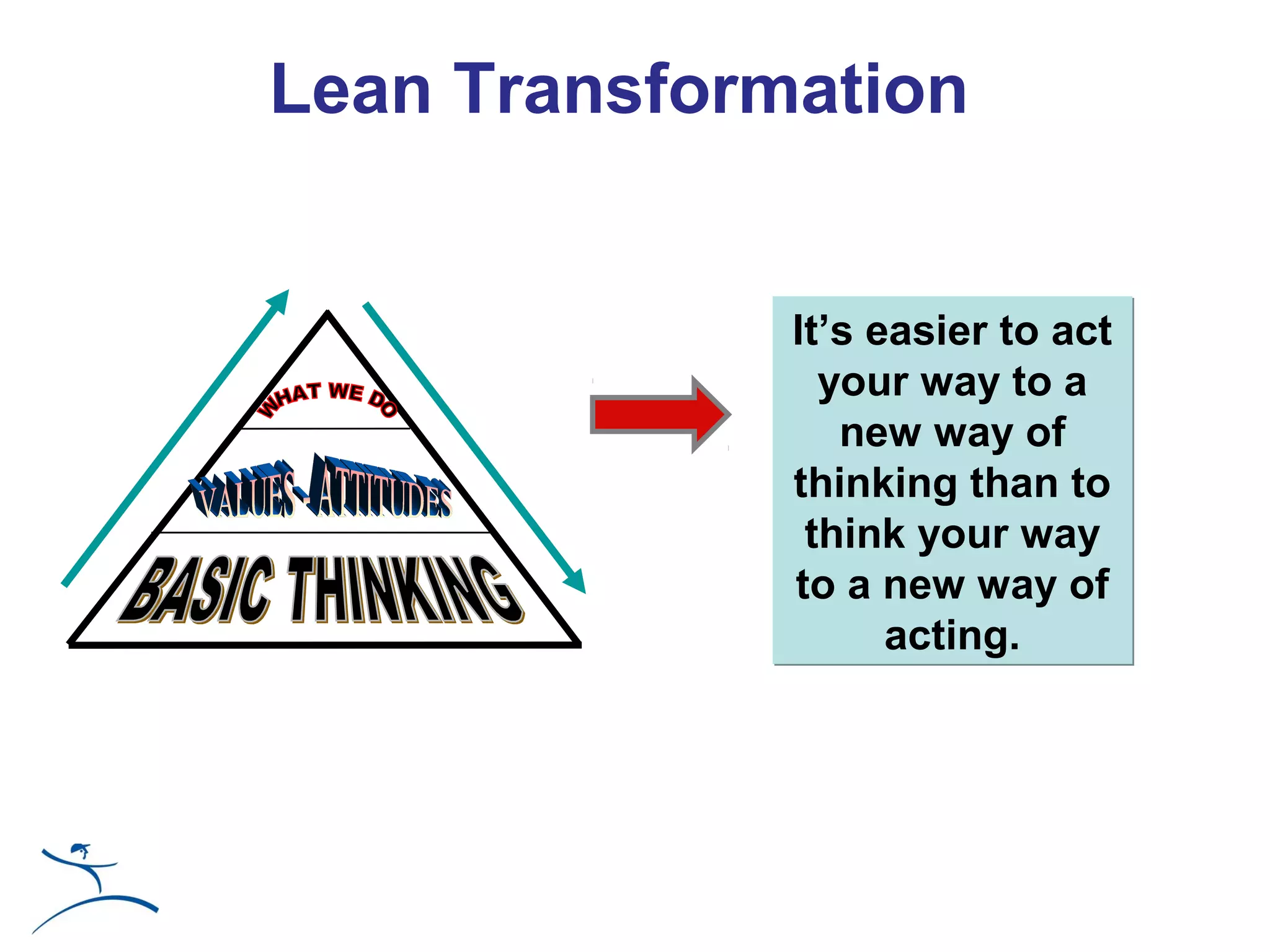

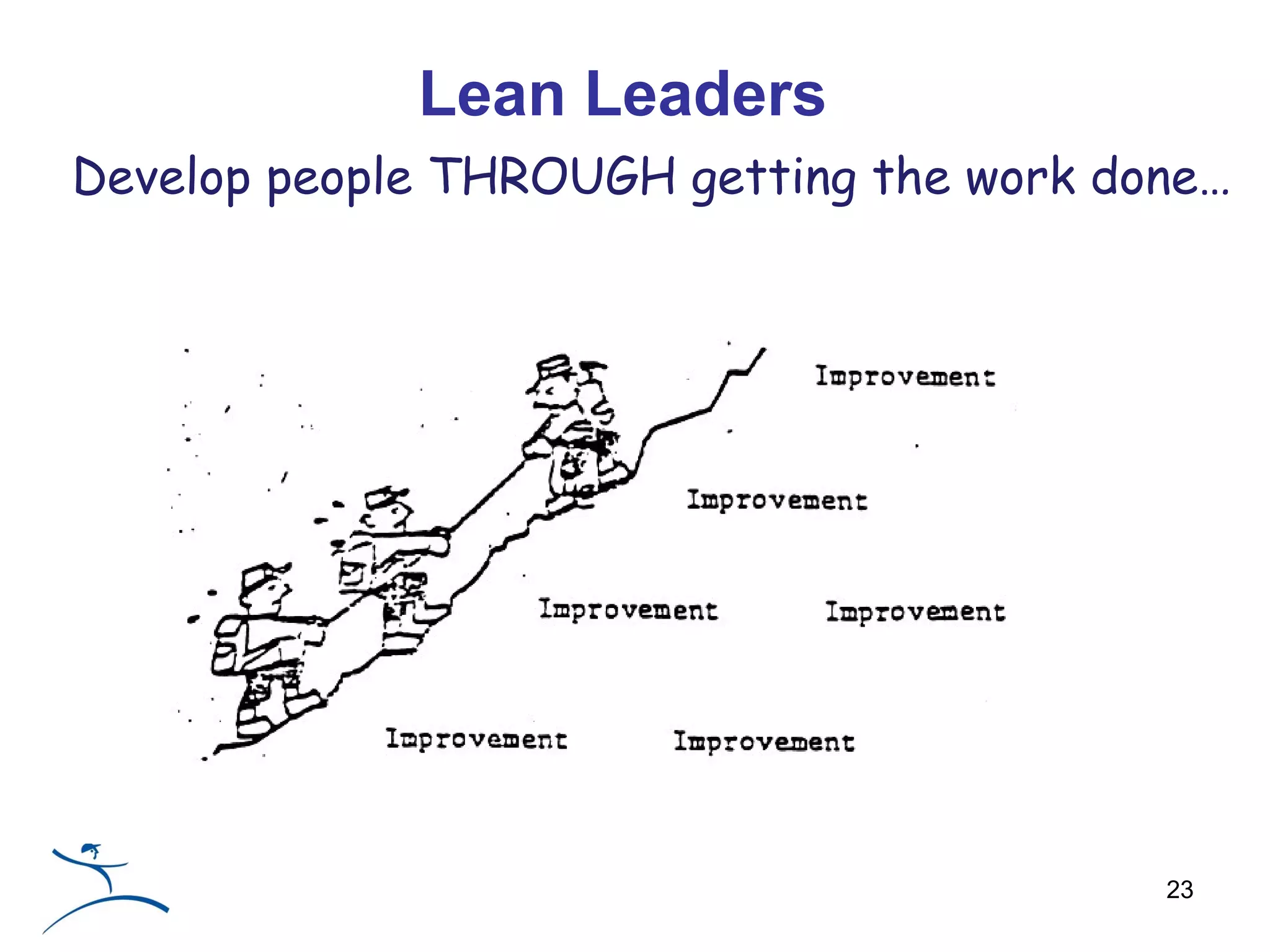

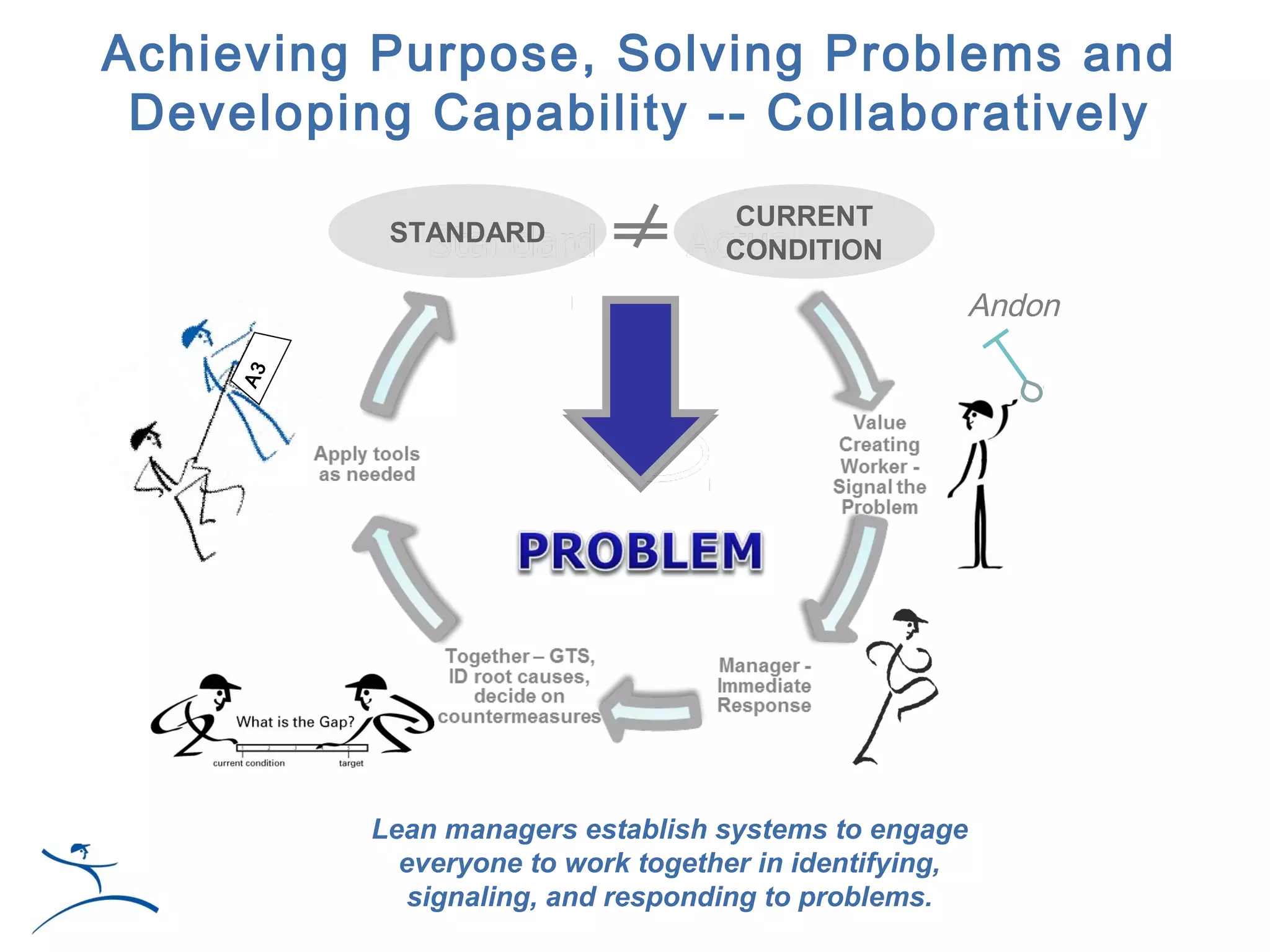

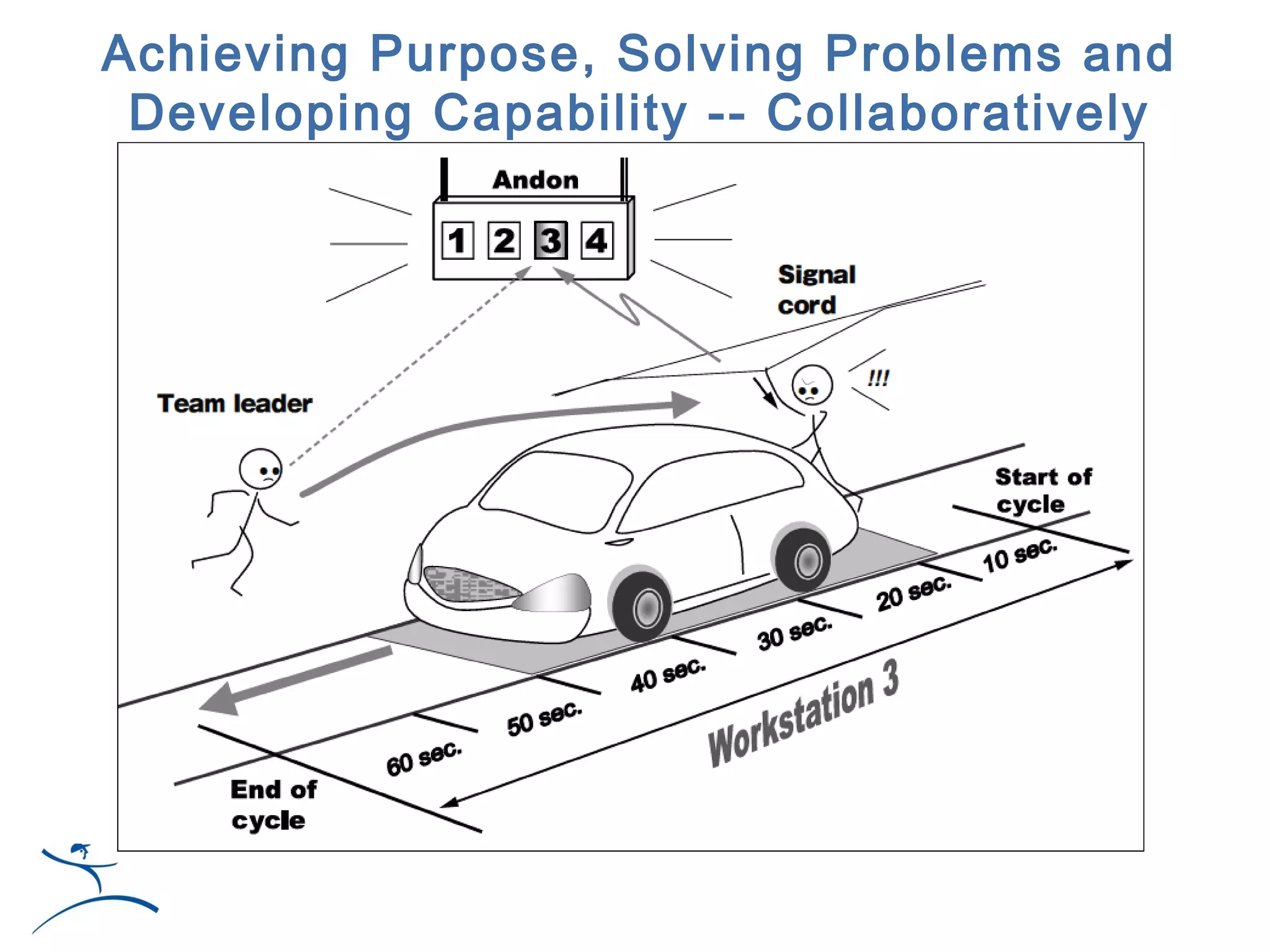

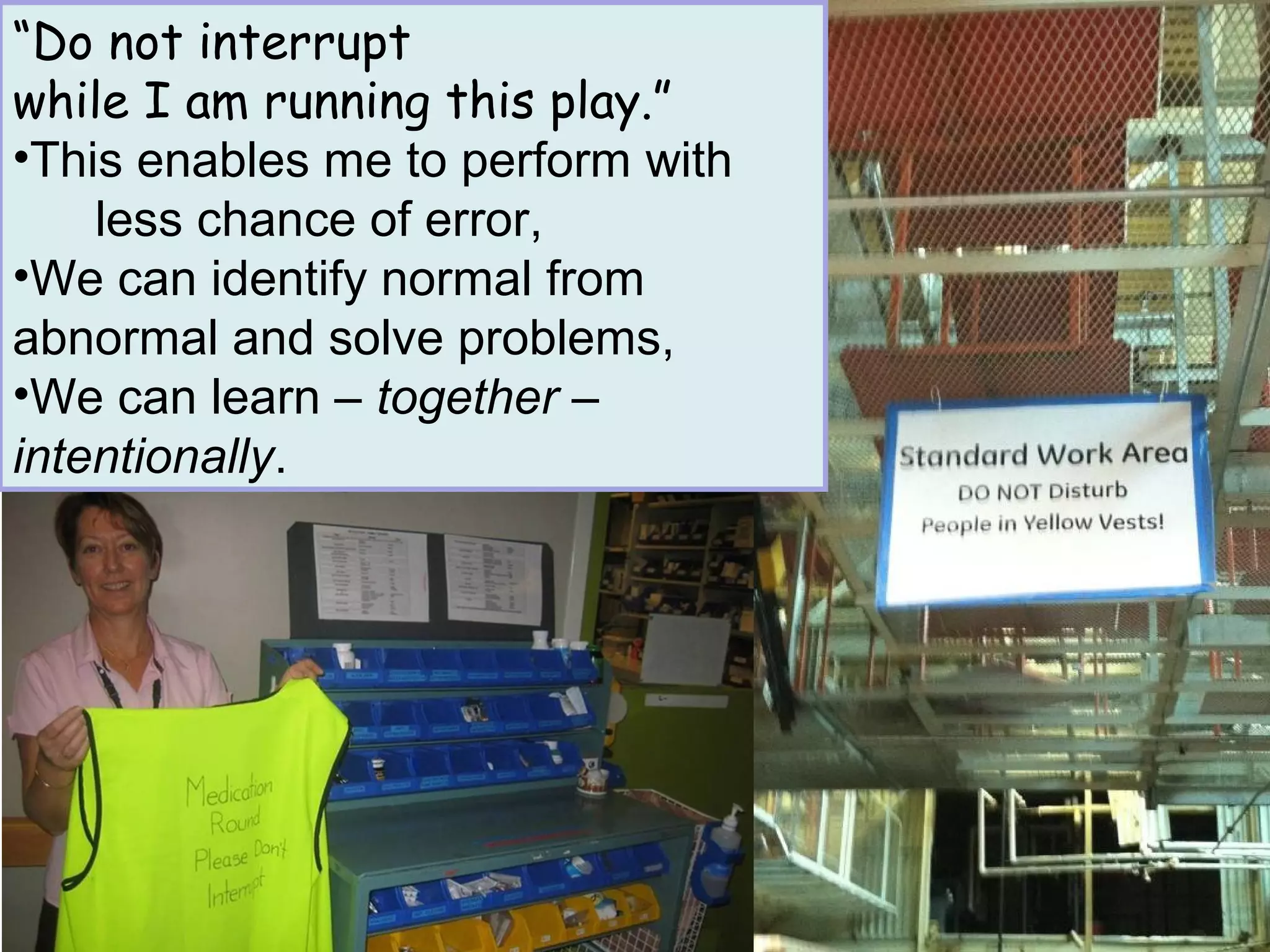

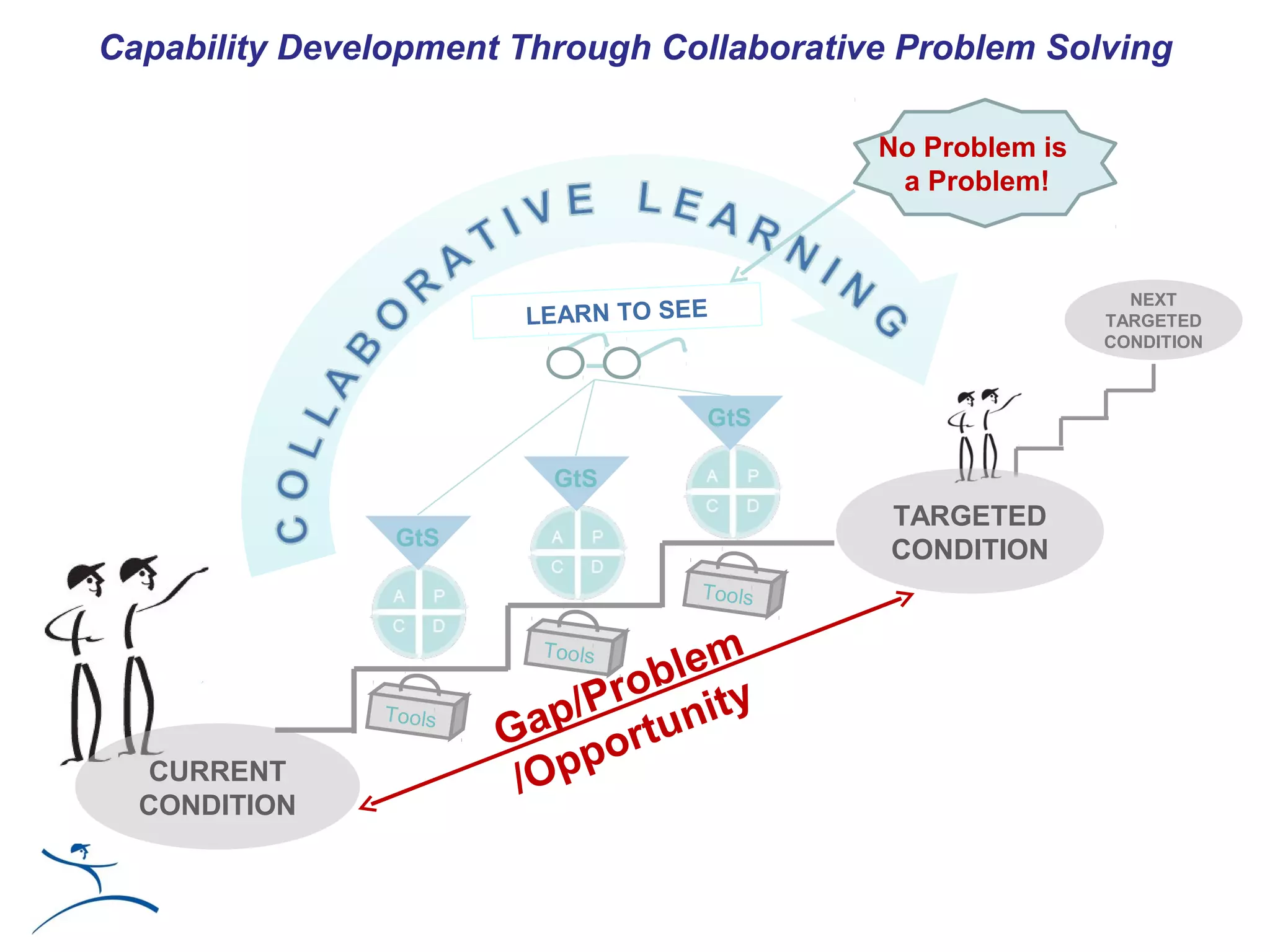

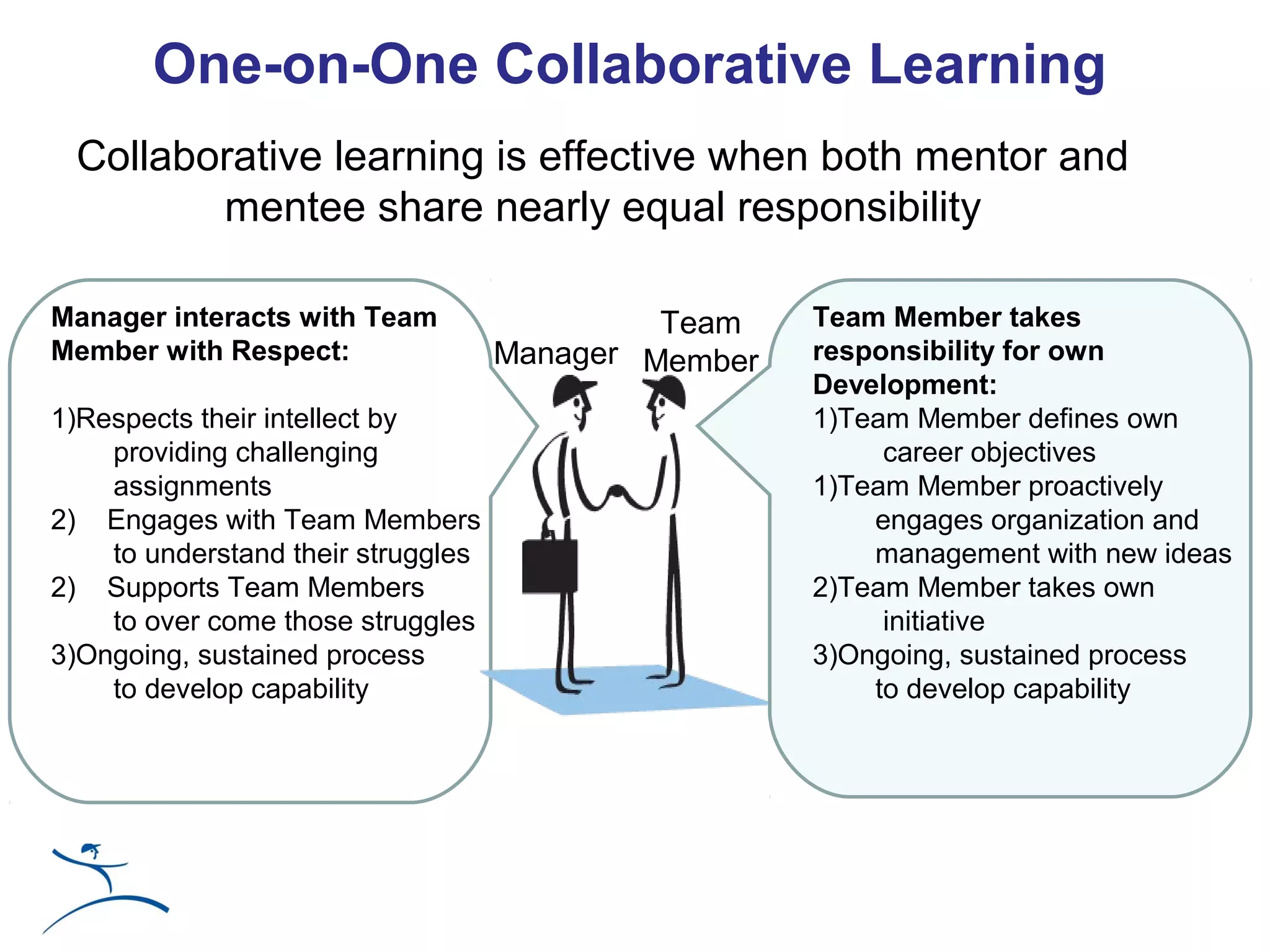

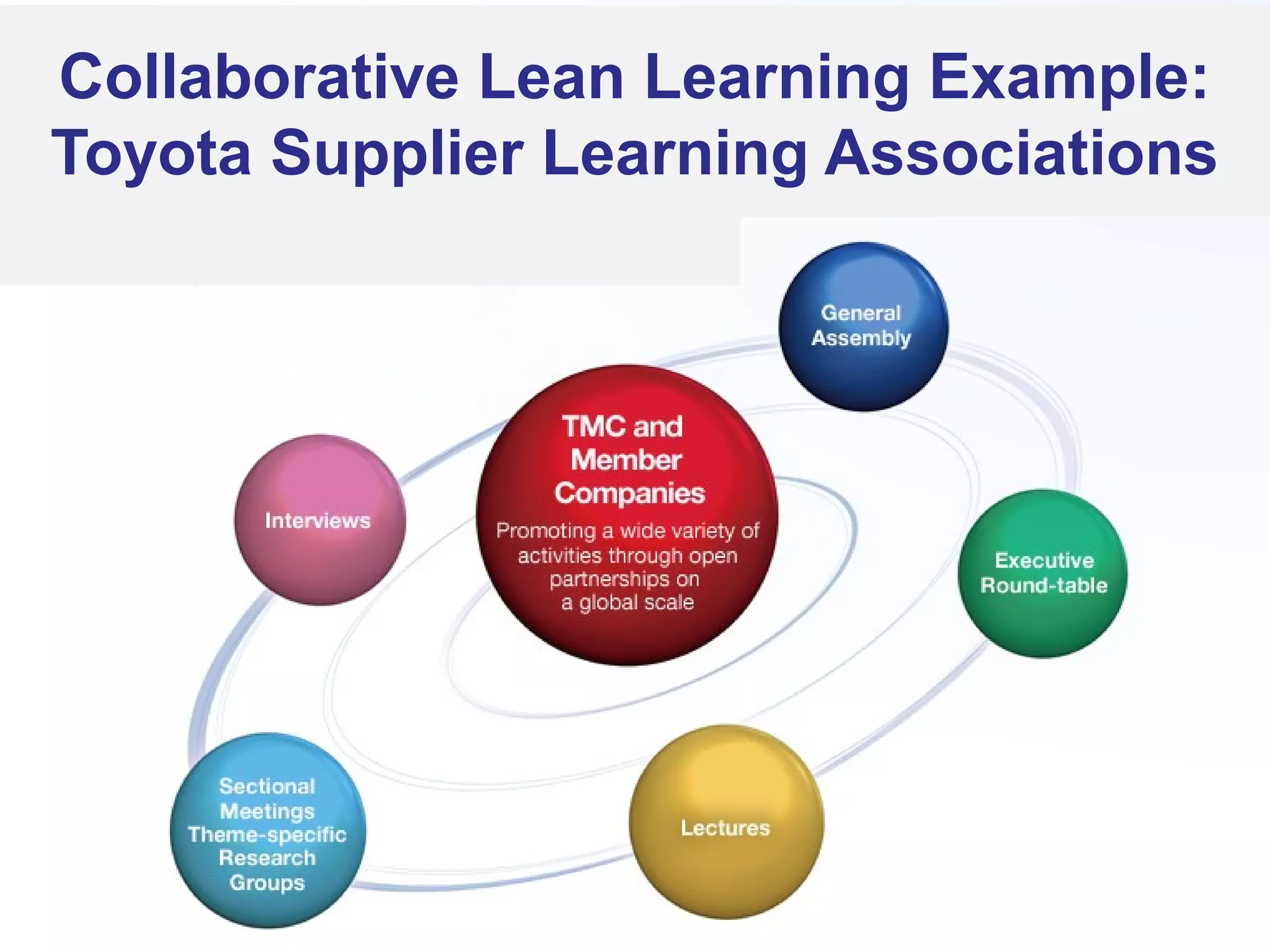

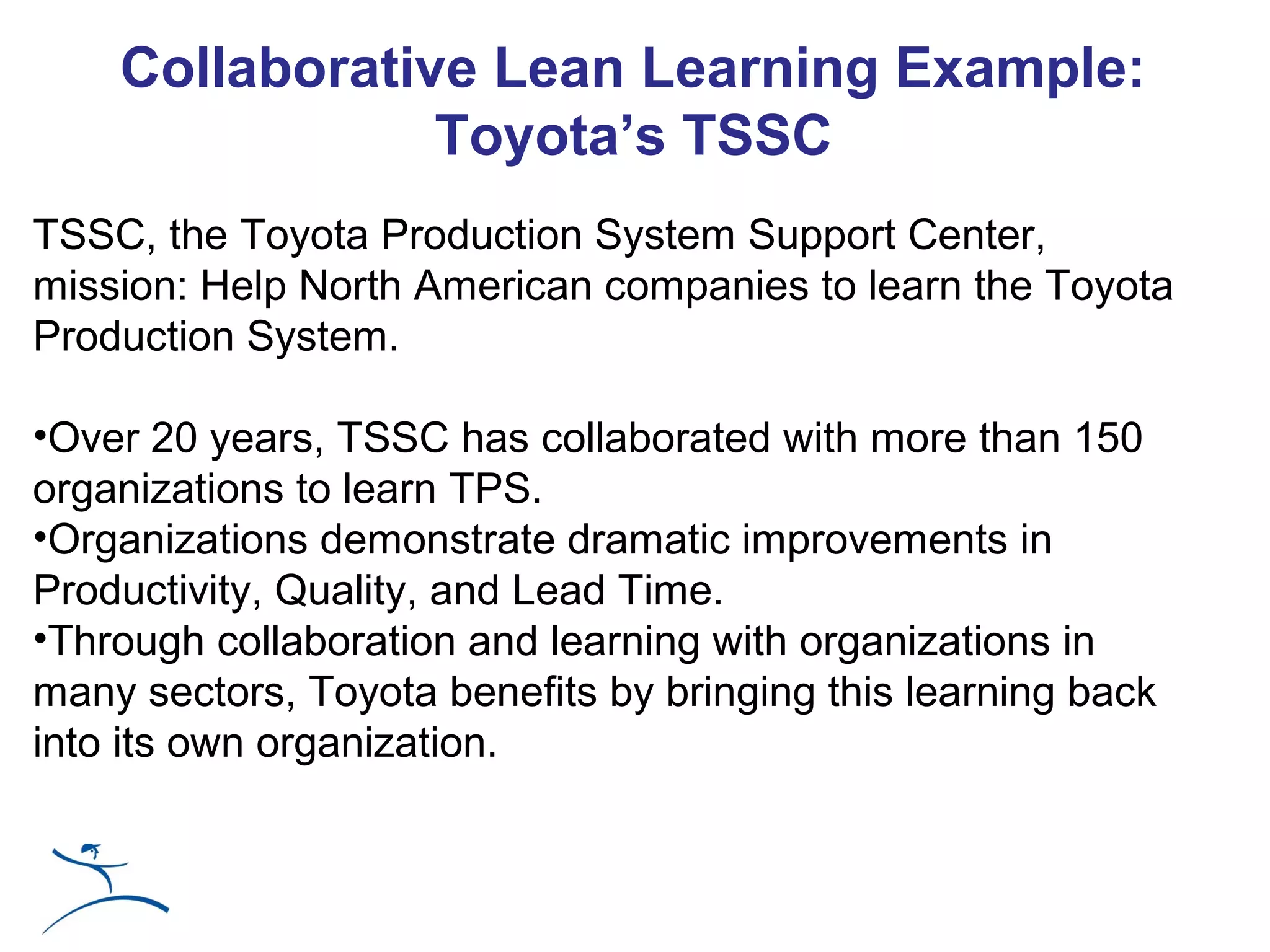

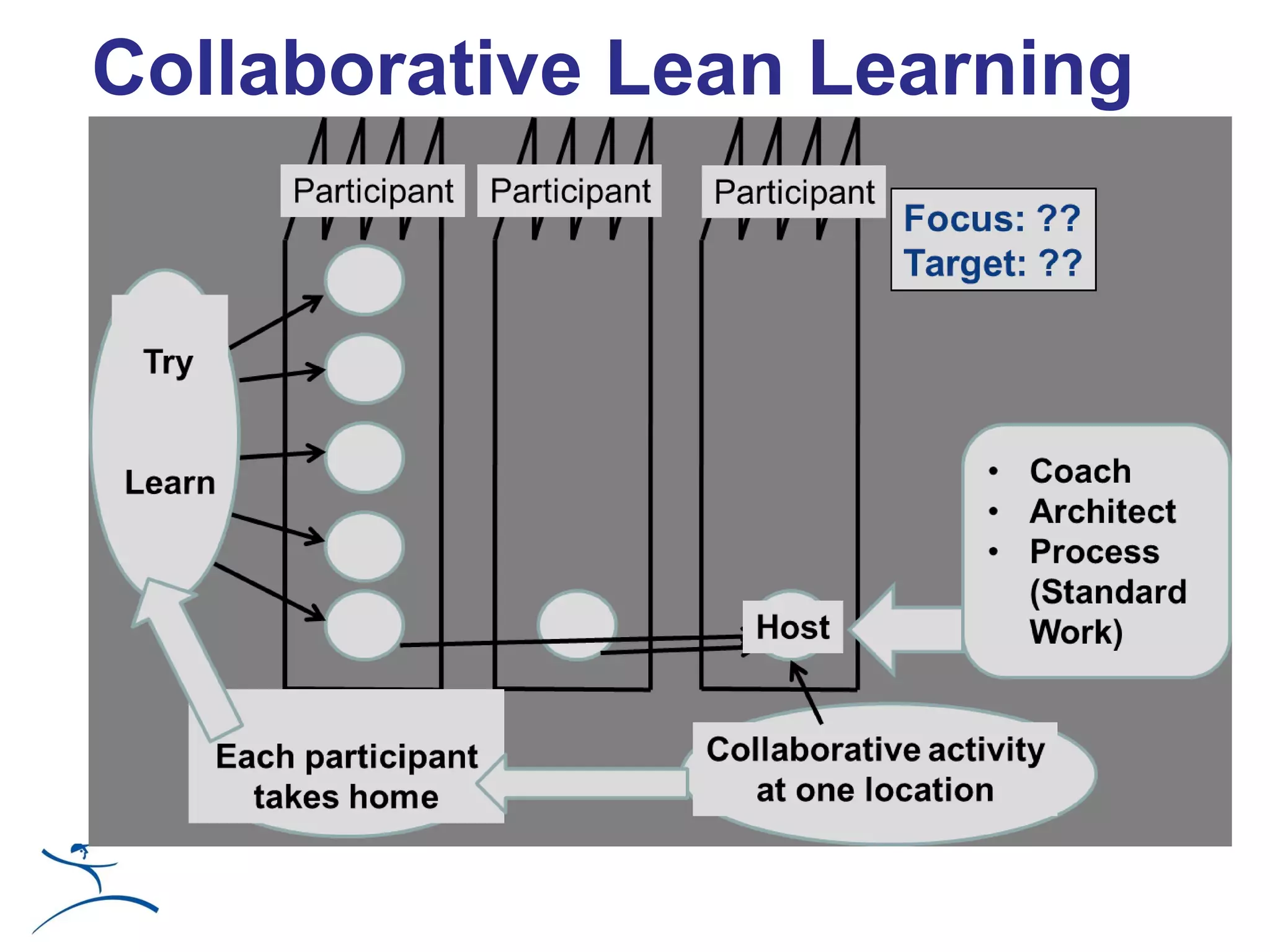

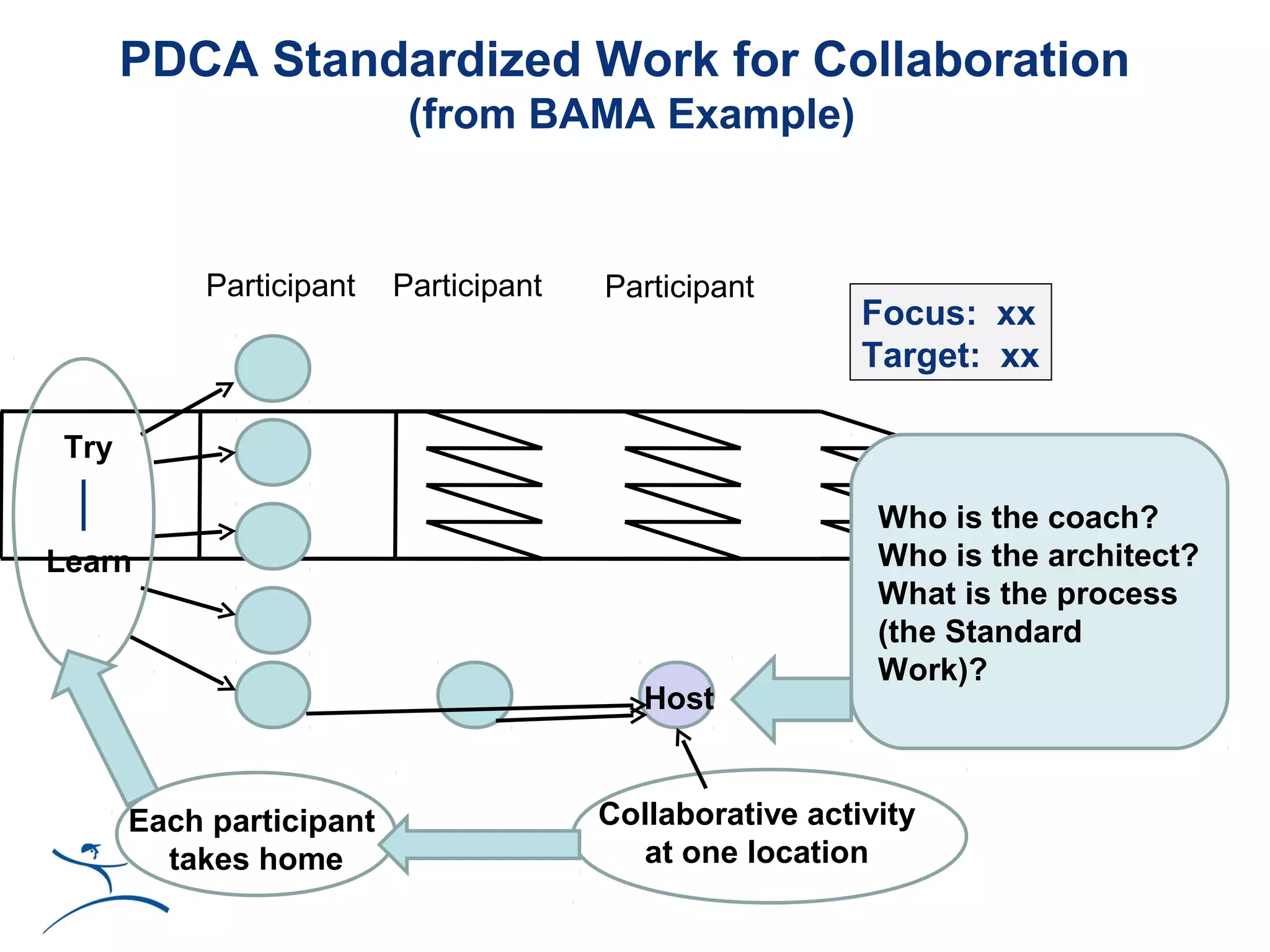

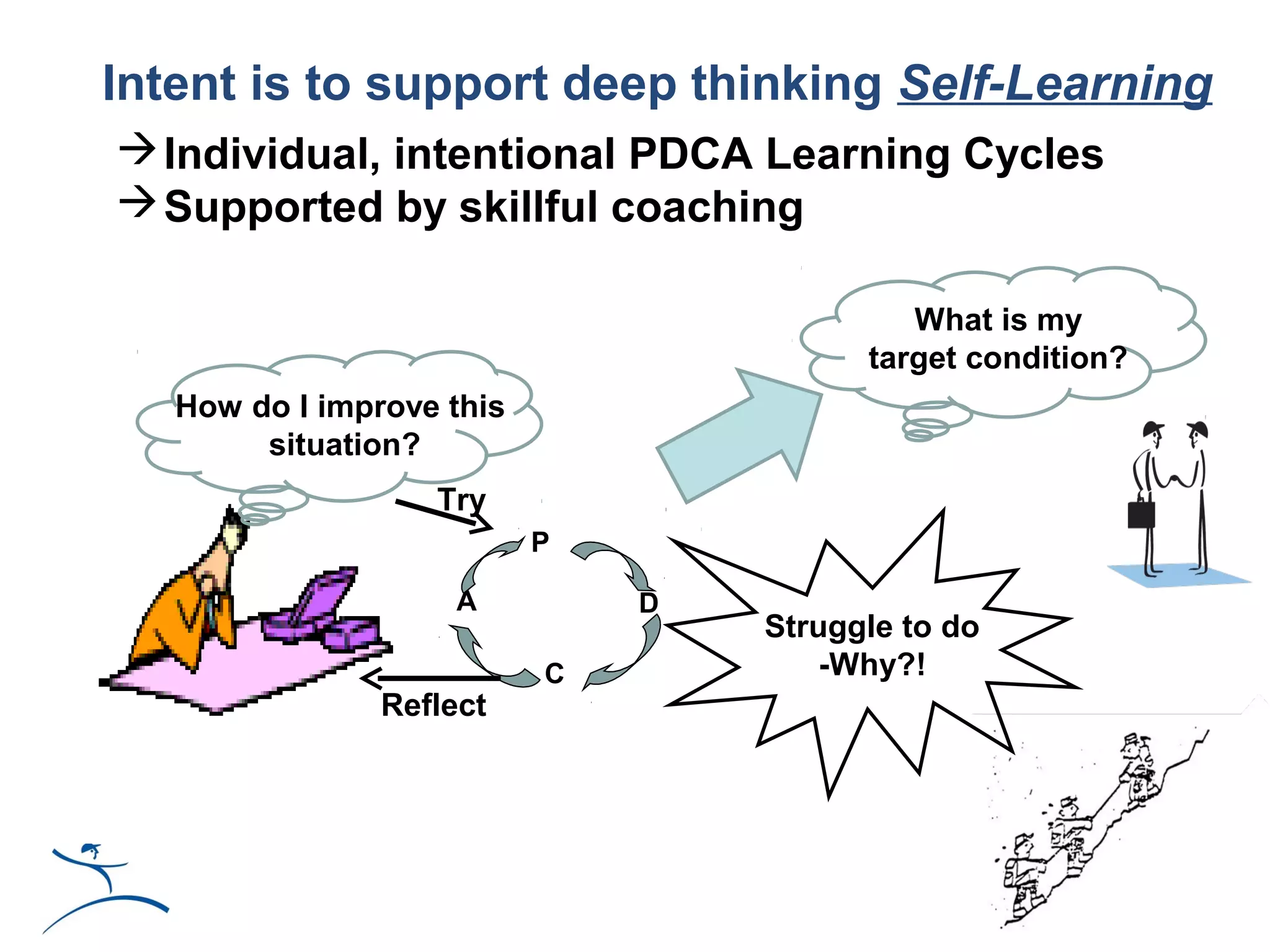

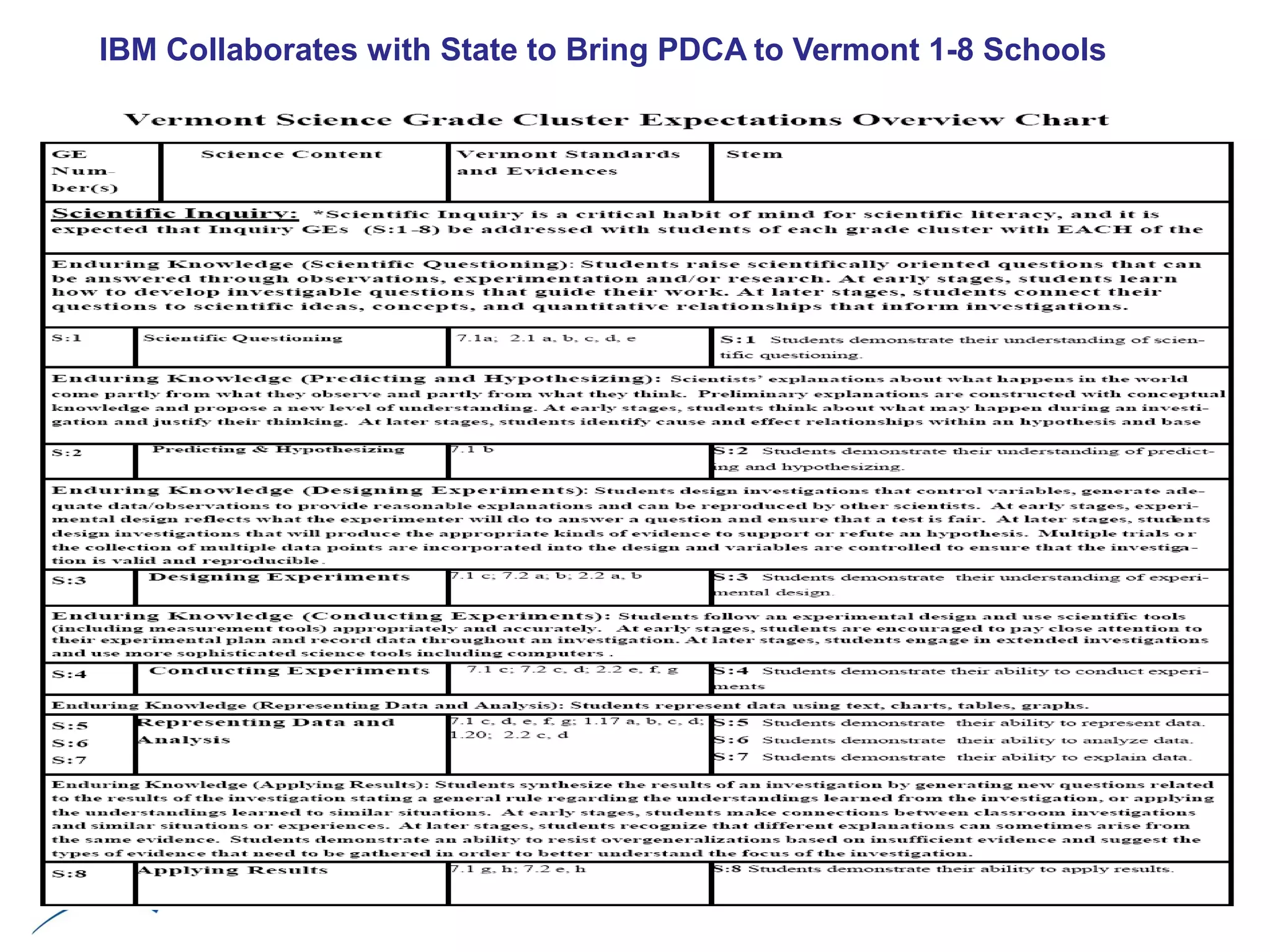

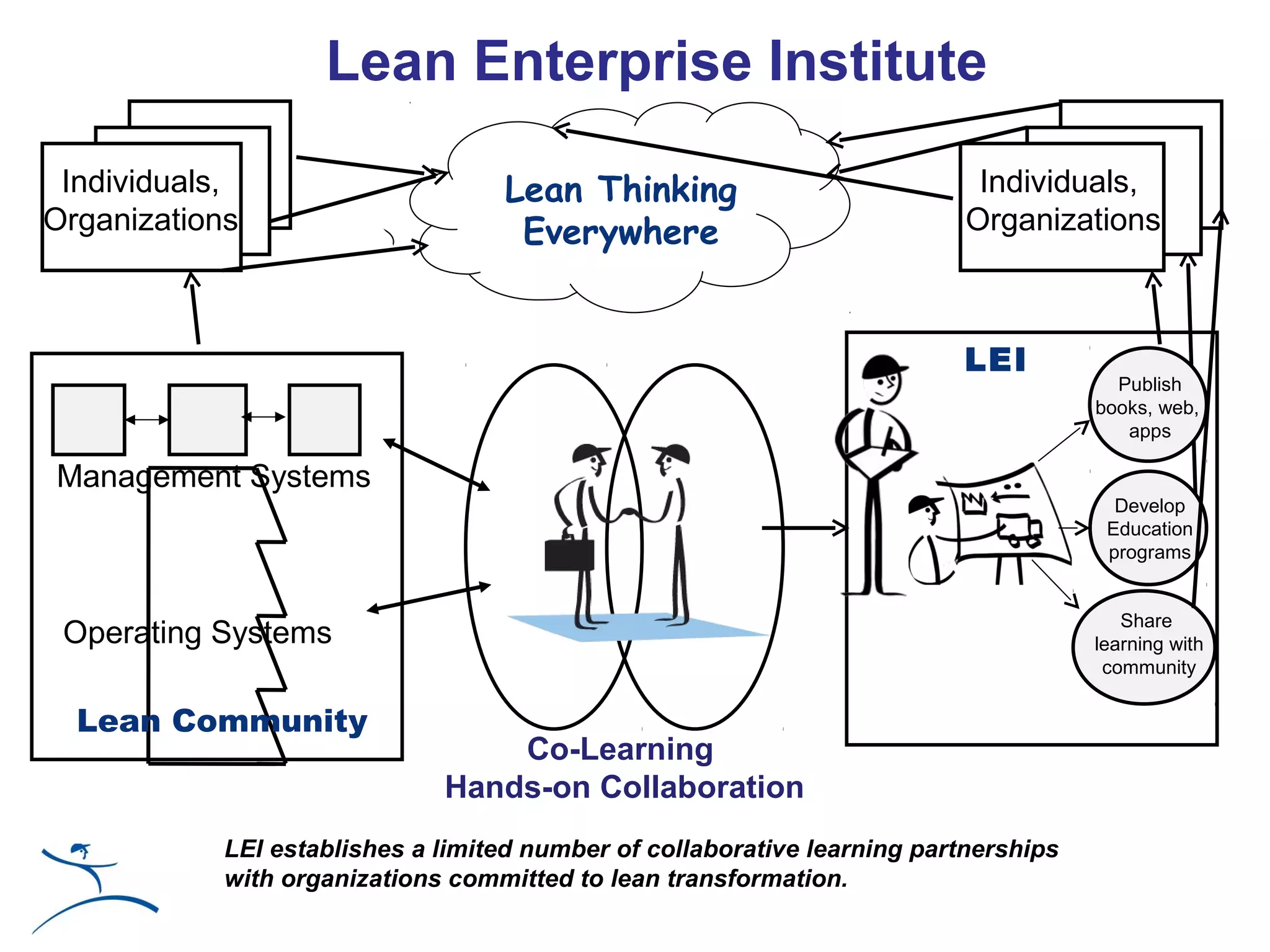

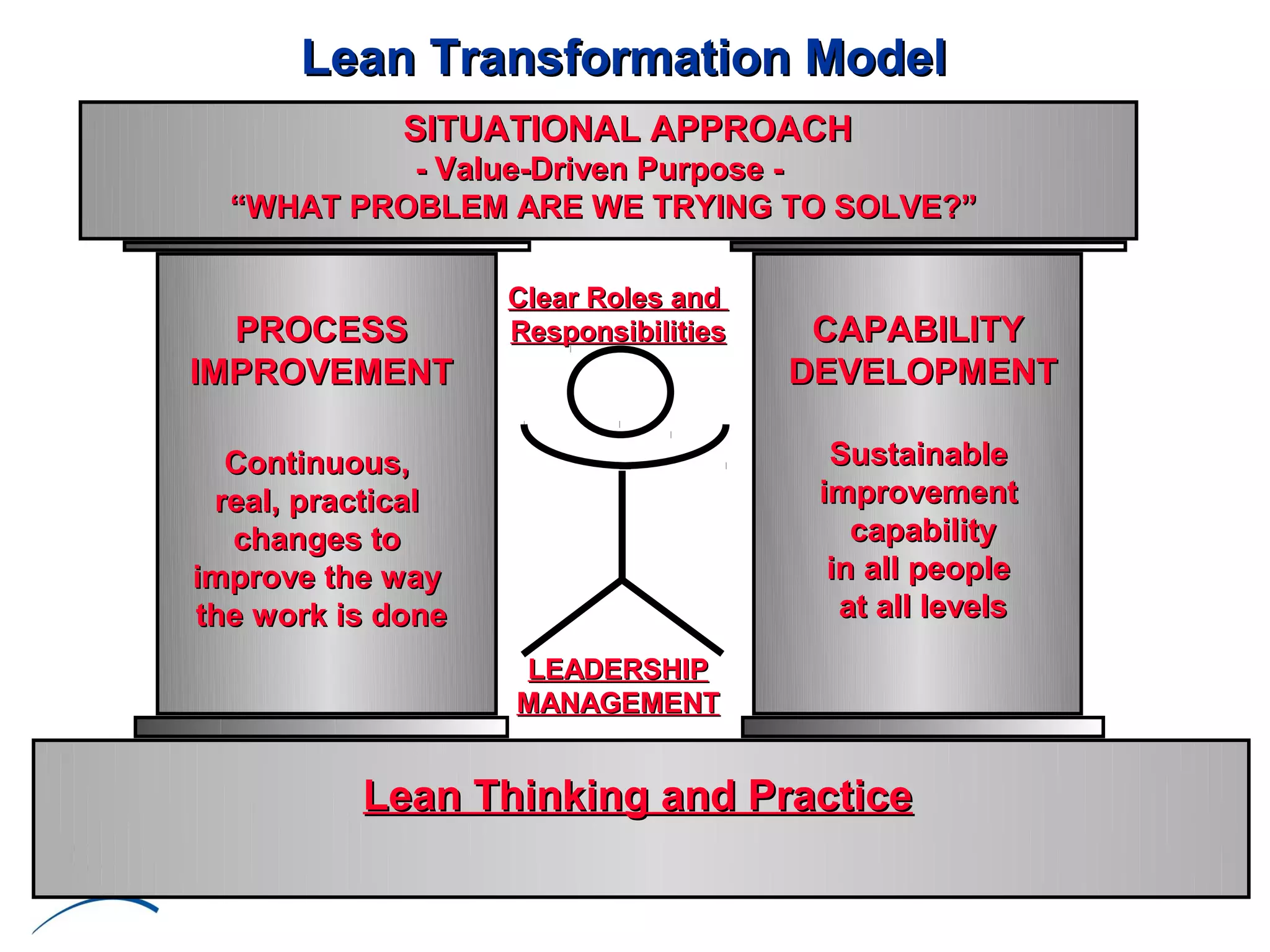

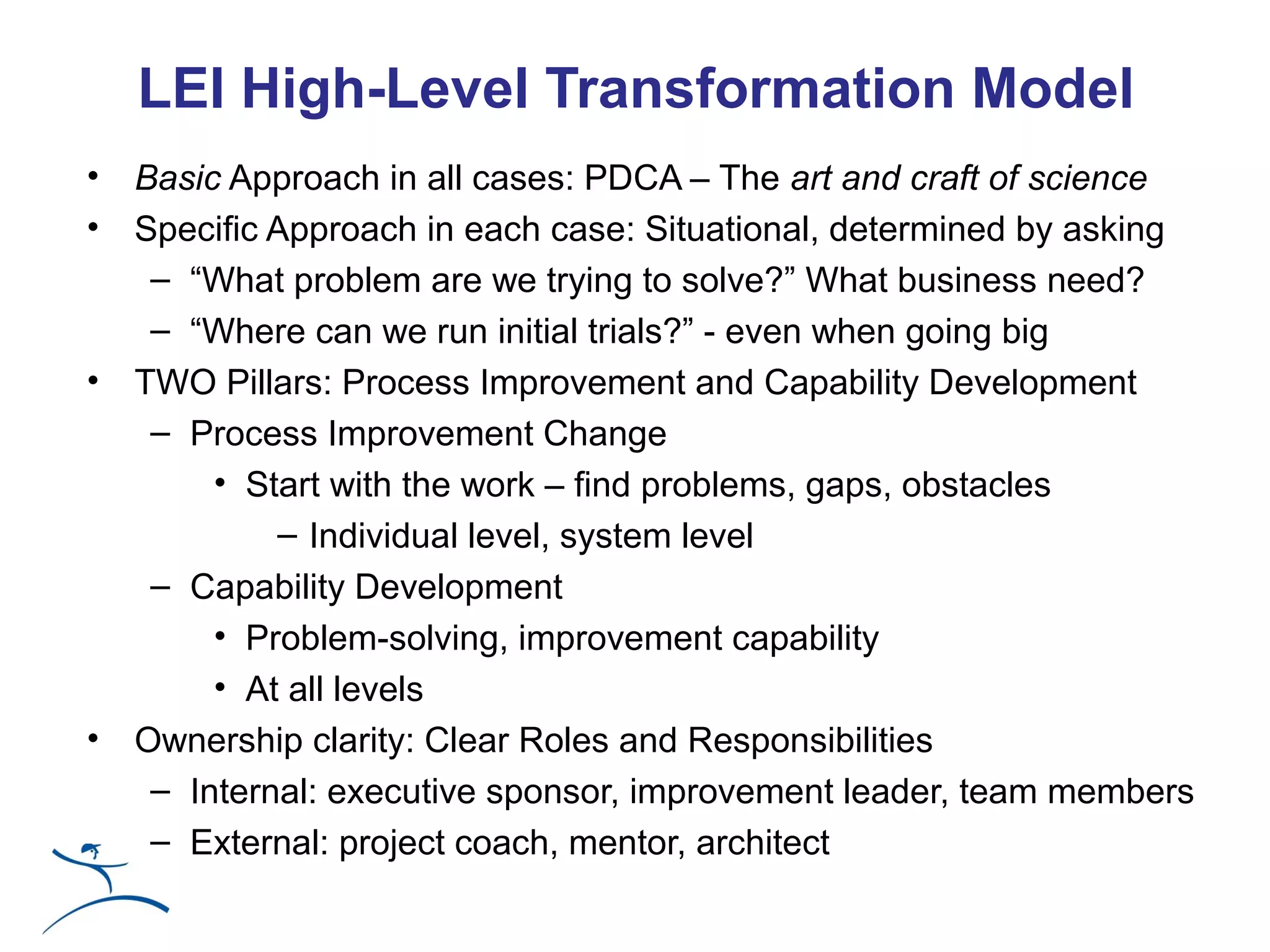

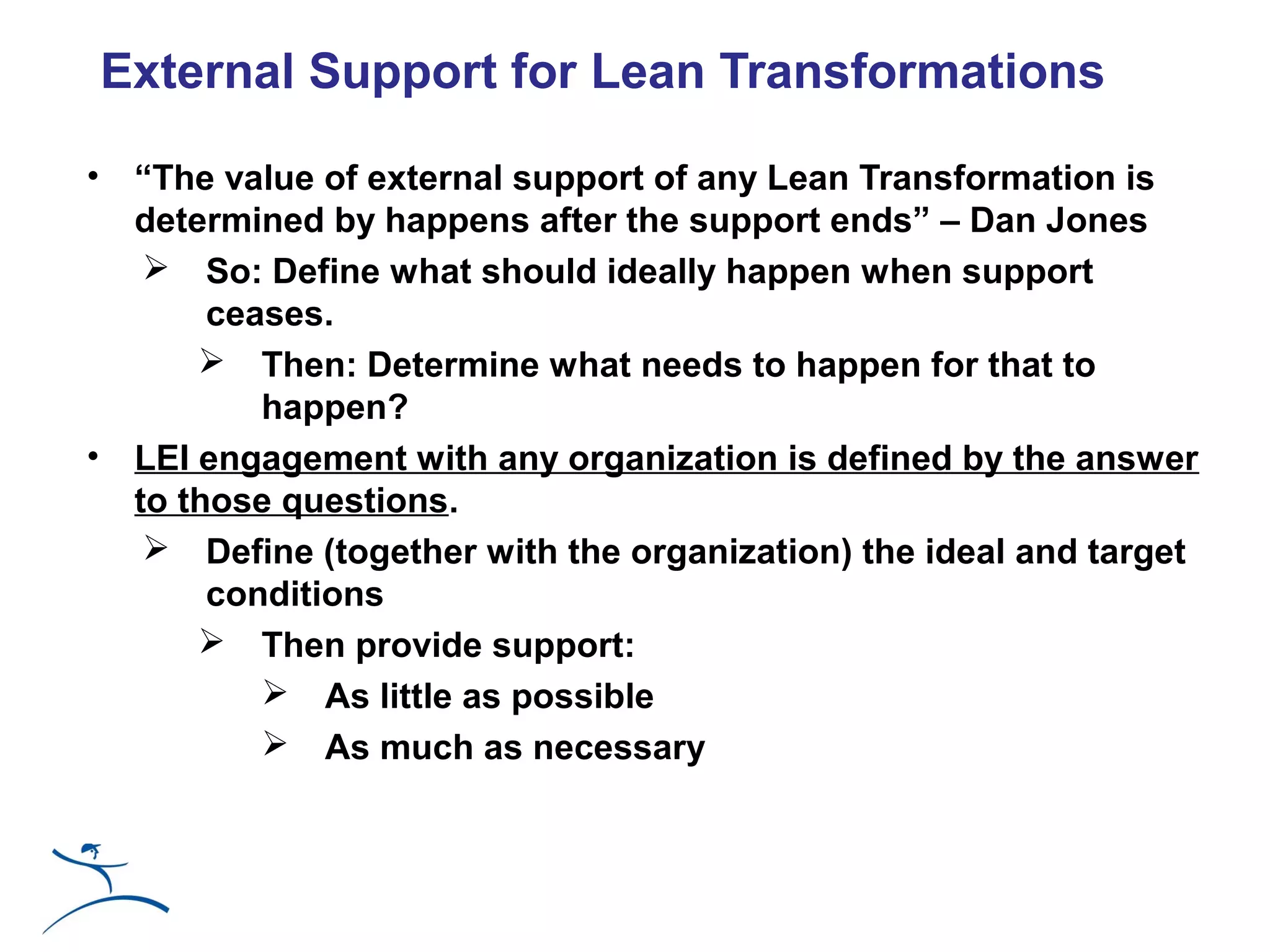

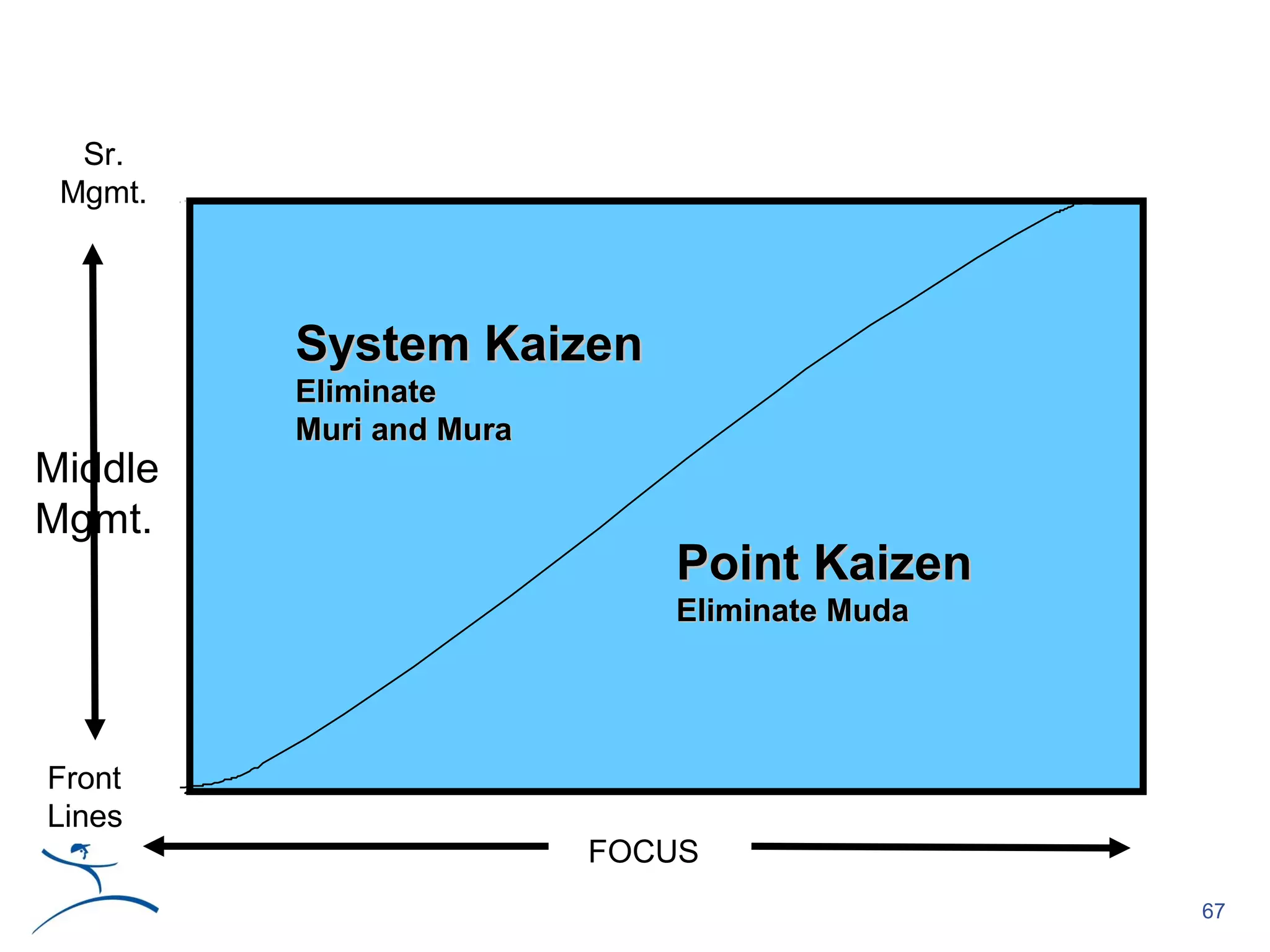

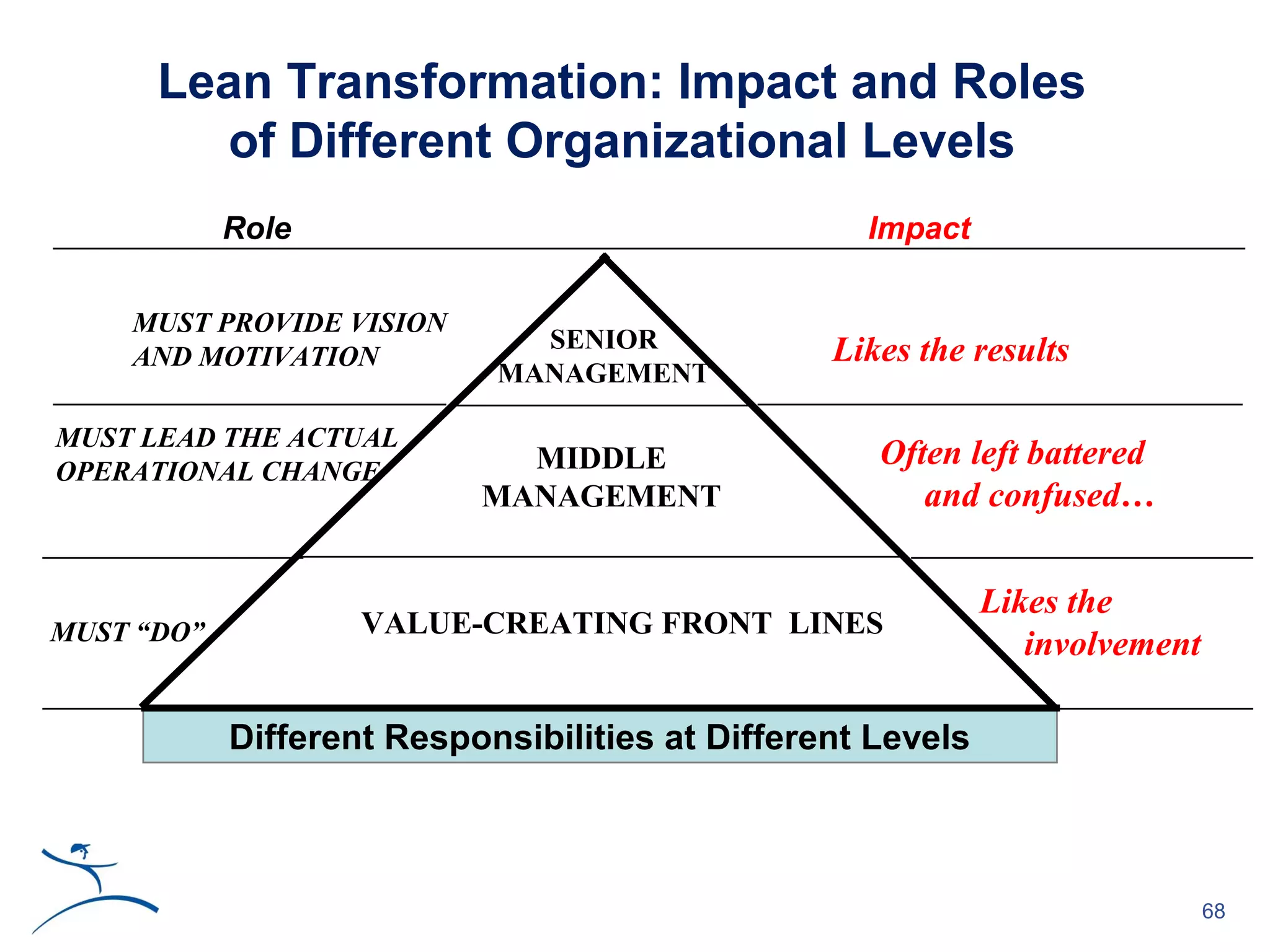

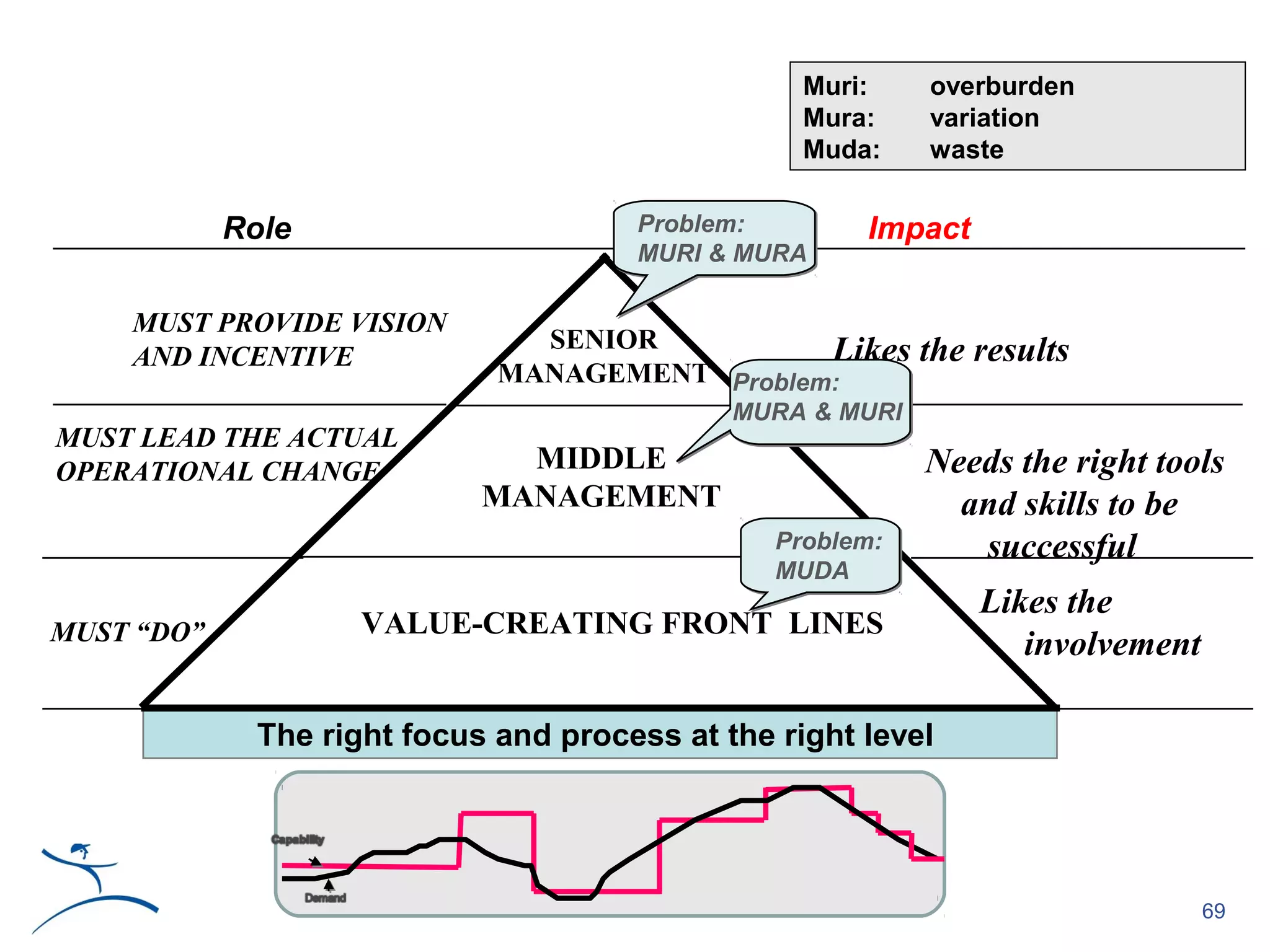

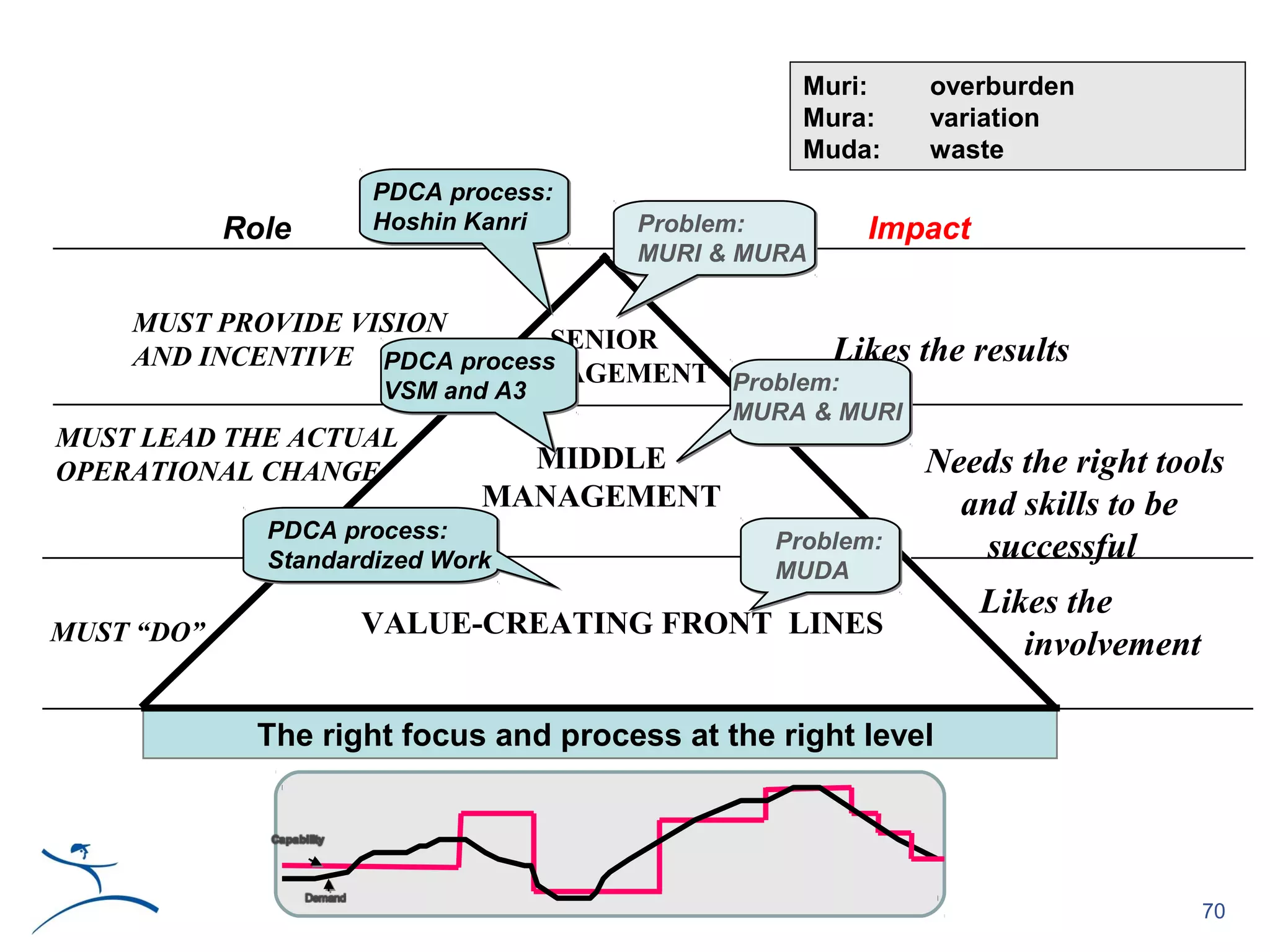

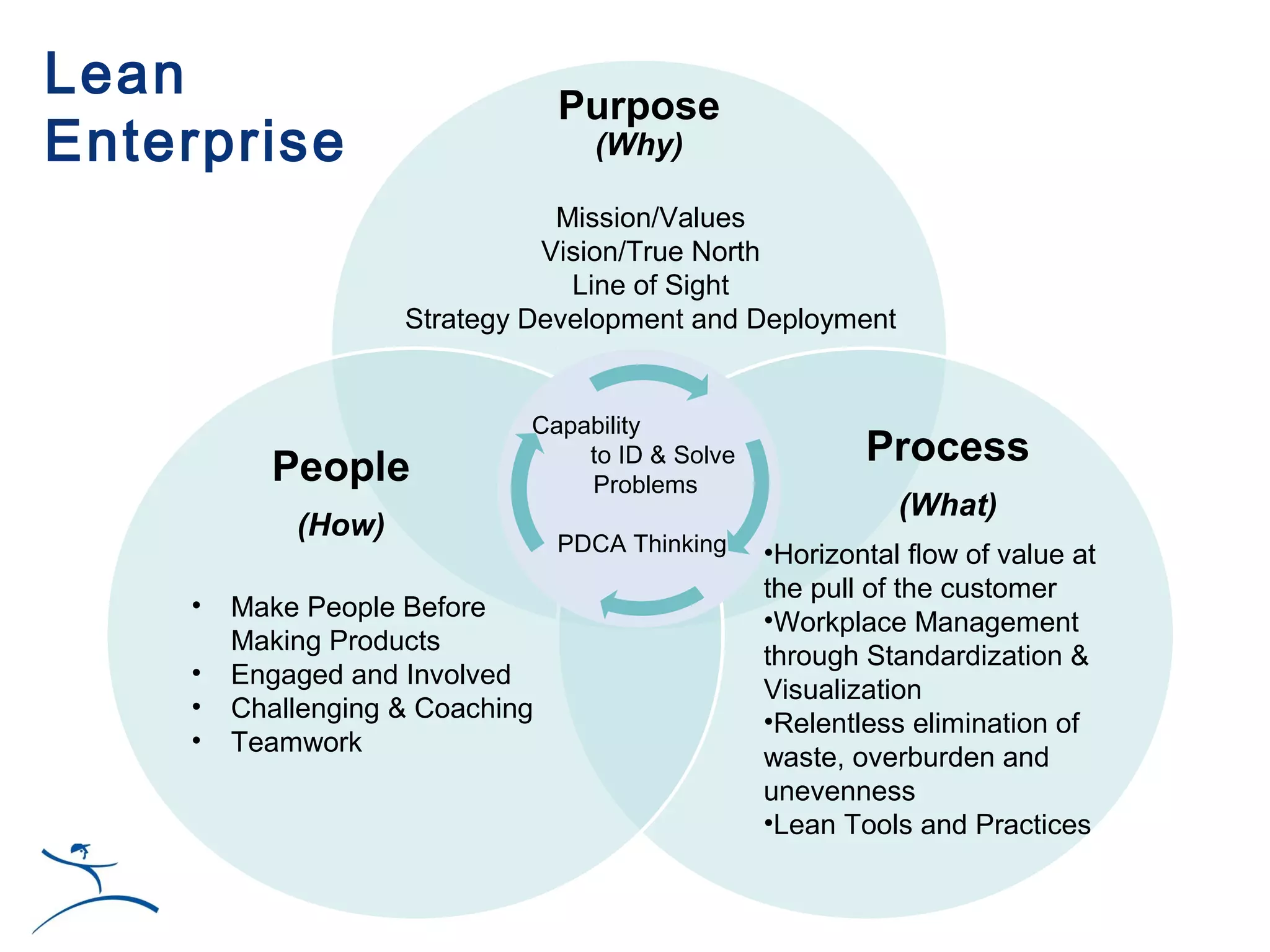

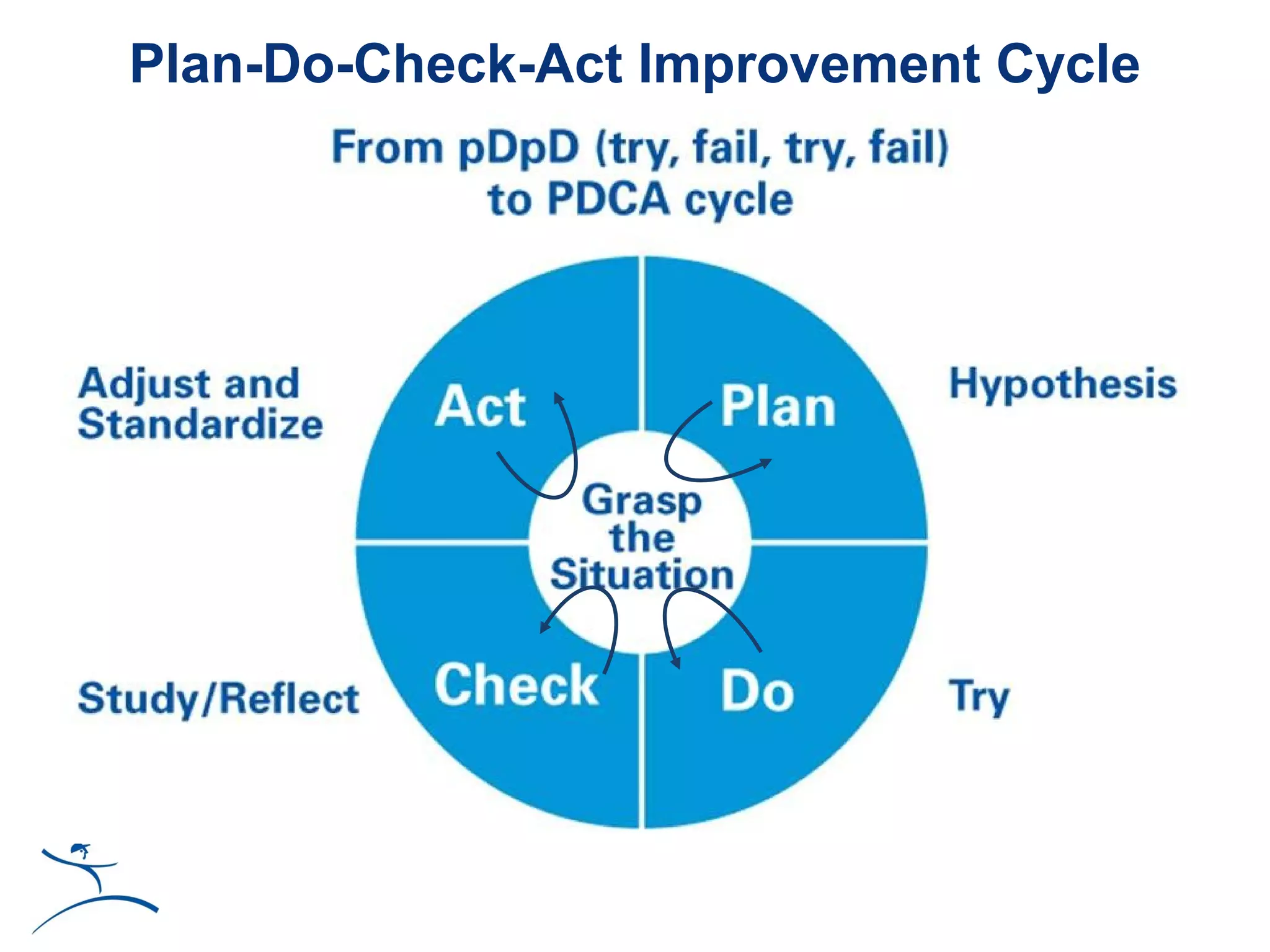

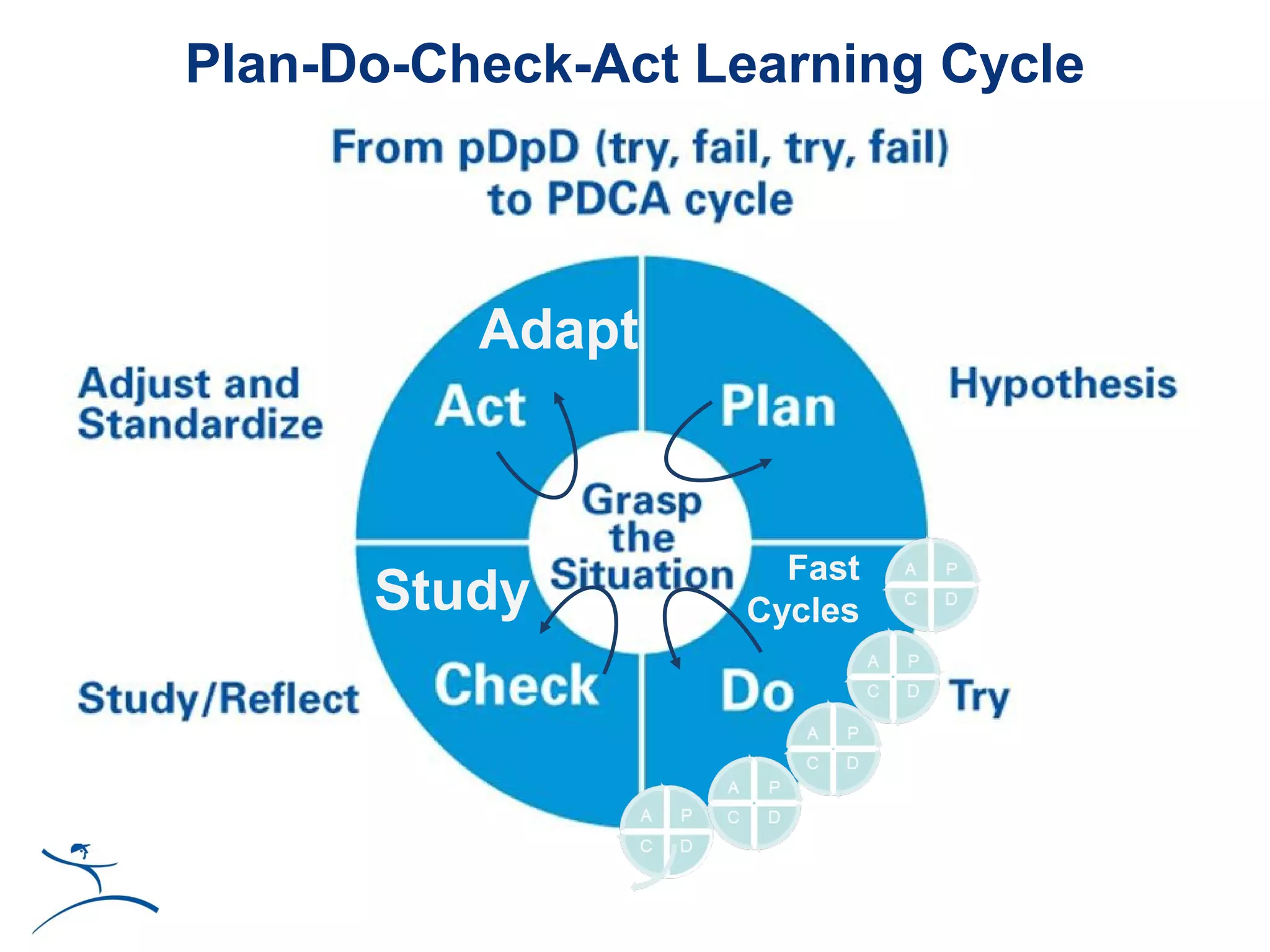

The document discusses lean thinking and collaborative learning as essential components for organizational transformation, emphasizing the importance of shared knowledge and continuous improvement. It highlights the role of management in aligning purpose, process, and people while transforming organizational culture and systems through structured problem-solving and learning cycles. Additionally, it outlines the significance of collaborative mechanisms and relationships in achieving successful lean transformations and developing people's capabilities.