The document discusses lean transformation and the lean global network. It provides:

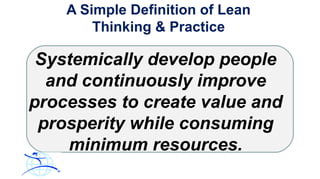

1) An overview of the Lean Global Network which is a network of institutes working to bring lean thinking and practices to their countries to improve organizational performance, raise living standards, and enable more fulfilling work.

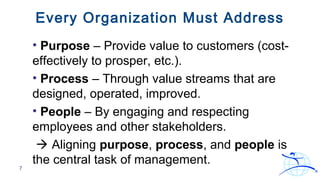

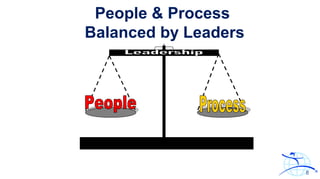

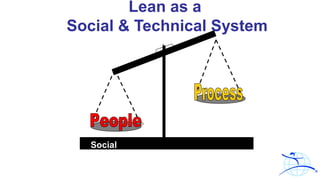

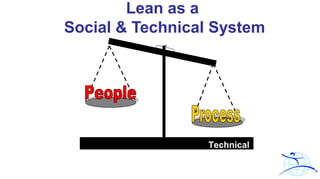

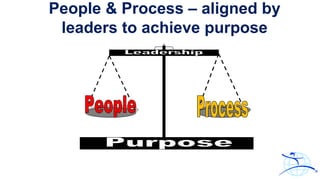

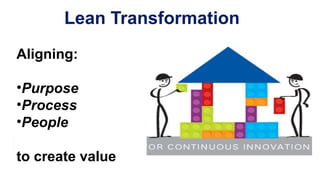

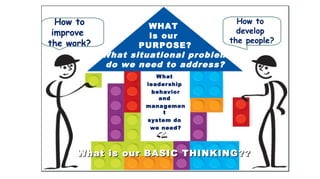

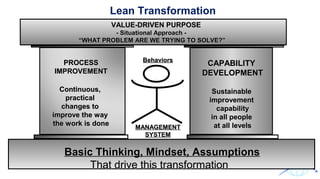

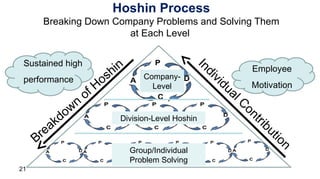

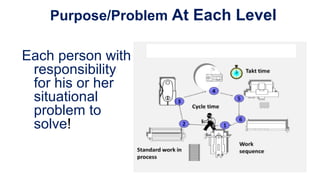

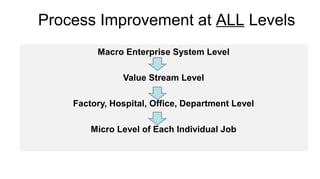

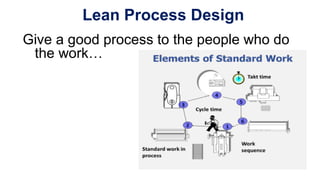

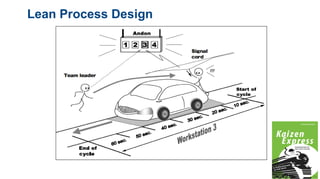

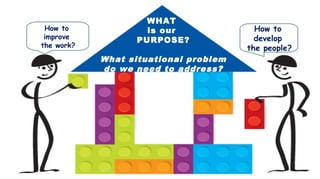

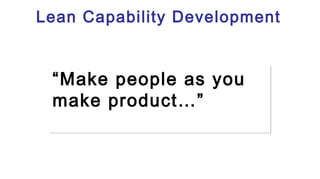

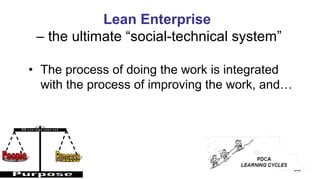

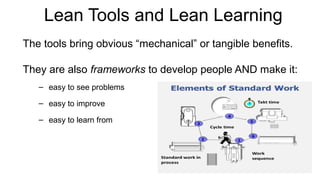

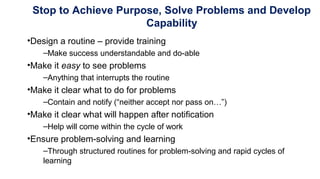

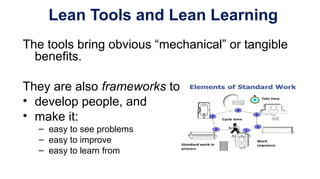

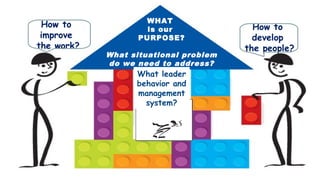

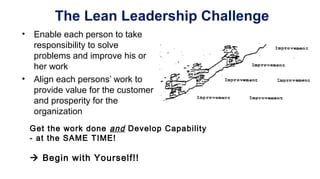

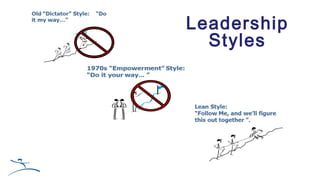

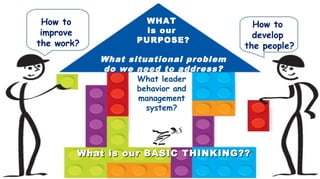

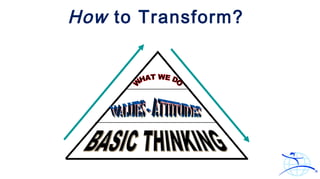

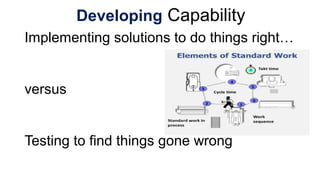

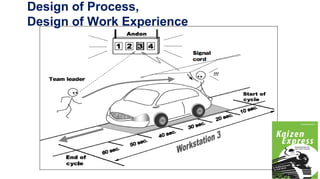

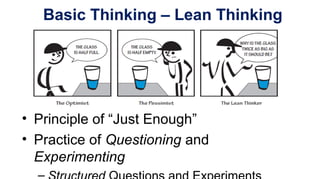

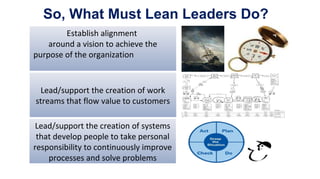

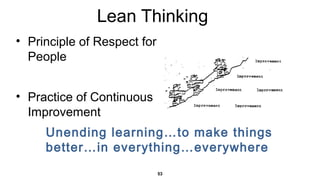

2) A model for lean transformation which involves aligning an organization's purpose, processes, and people development to create value. It emphasizes clear communication of purpose, continuous process improvement, and building capabilities.

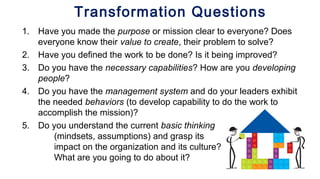

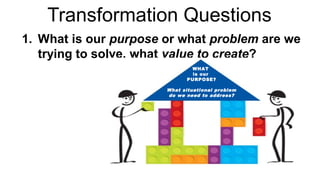

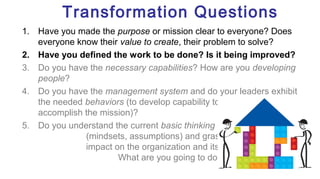

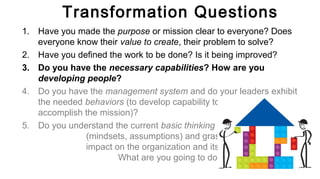

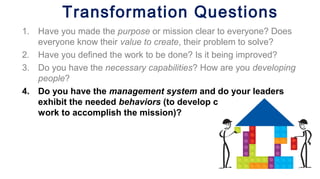

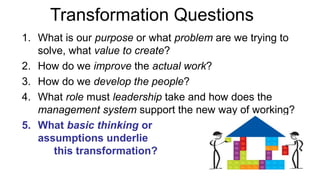

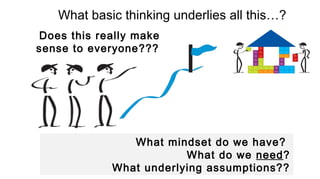

3) Questions organizations should consider around clearly defining their purpose and problem to solve, improving processes, developing employee capabilities, exhibiting the right leadership behaviors, and assessing underlying assumptions.