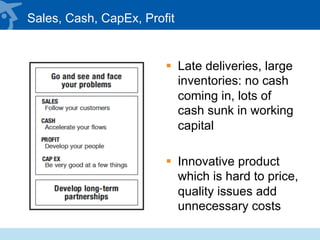

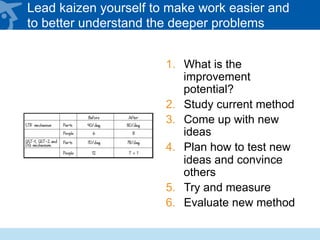

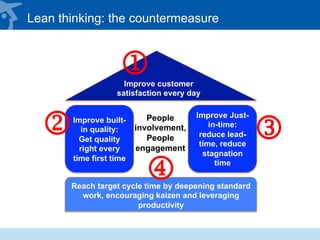

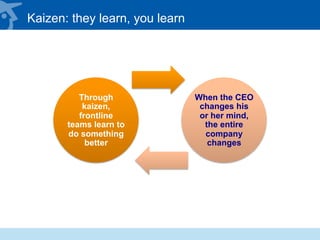

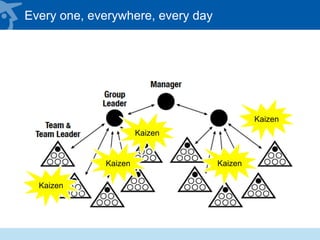

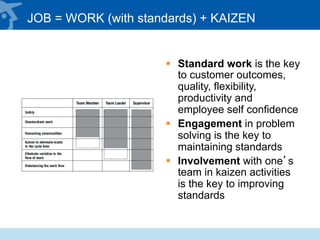

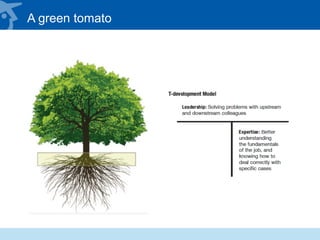

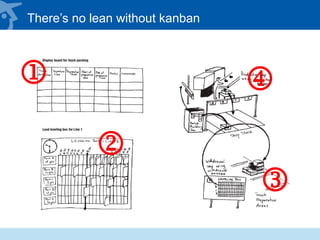

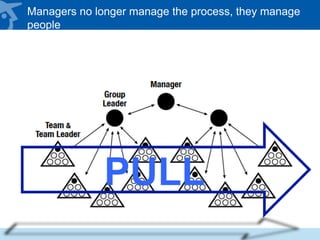

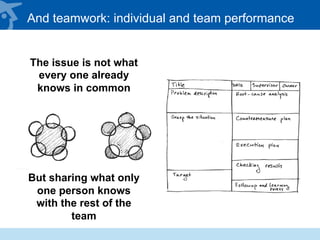

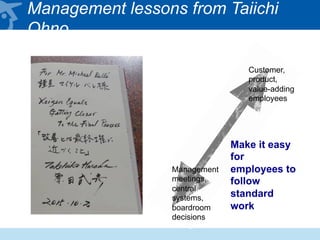

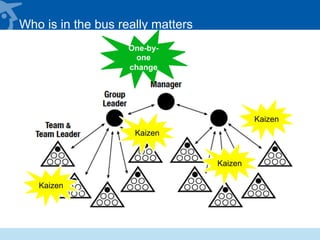

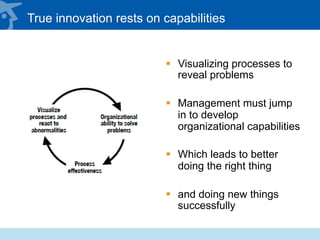

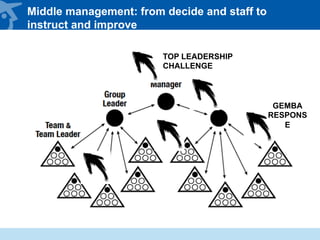

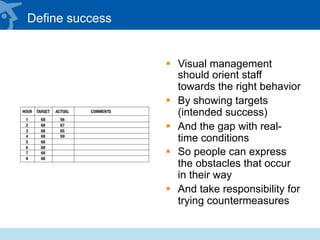

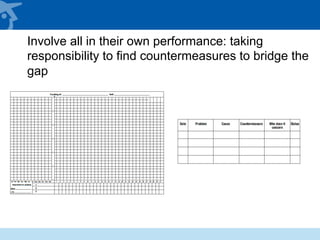

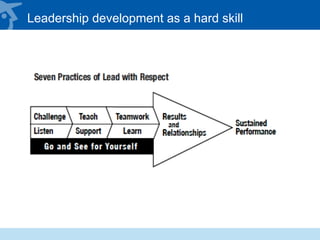

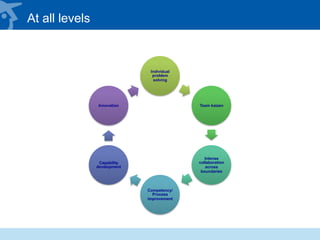

Michael Ballé presented on lean management principles and culture change. He discussed how managers can lead by going to the gemba (workplace) to observe problems firsthand and lead kaizen (continuous improvement) activities. Small, incremental improvements can lead to large-scale change over time. Management's role shifts from deciding and directing to instructing employees and helping them improve their work. Developing leaders at all levels is key to sustainability.