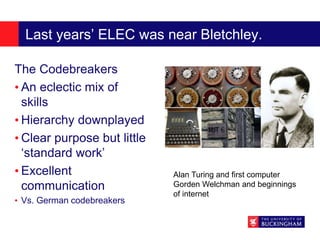

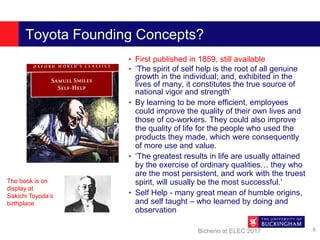

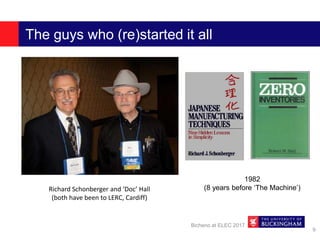

The document summarizes a talk given by John Bicheno at the Fourth European Lean Educator Conference in November 2017. The talk discusses concepts that have been forgotten, ignored, or represent new possibilities for Lean. These include early contributors to Lean like Lillian Gilbreth and Mary Follett, as well as ideas from operations research, behavioral economics, and agile methods. Bicheno argues that Lean must continue adapting and drawing from other fields to remain relevant in a changing world. Maintaining a flexible mindset and pursuing incremental improvements through small wins were presented as ways for Lean to evolve.