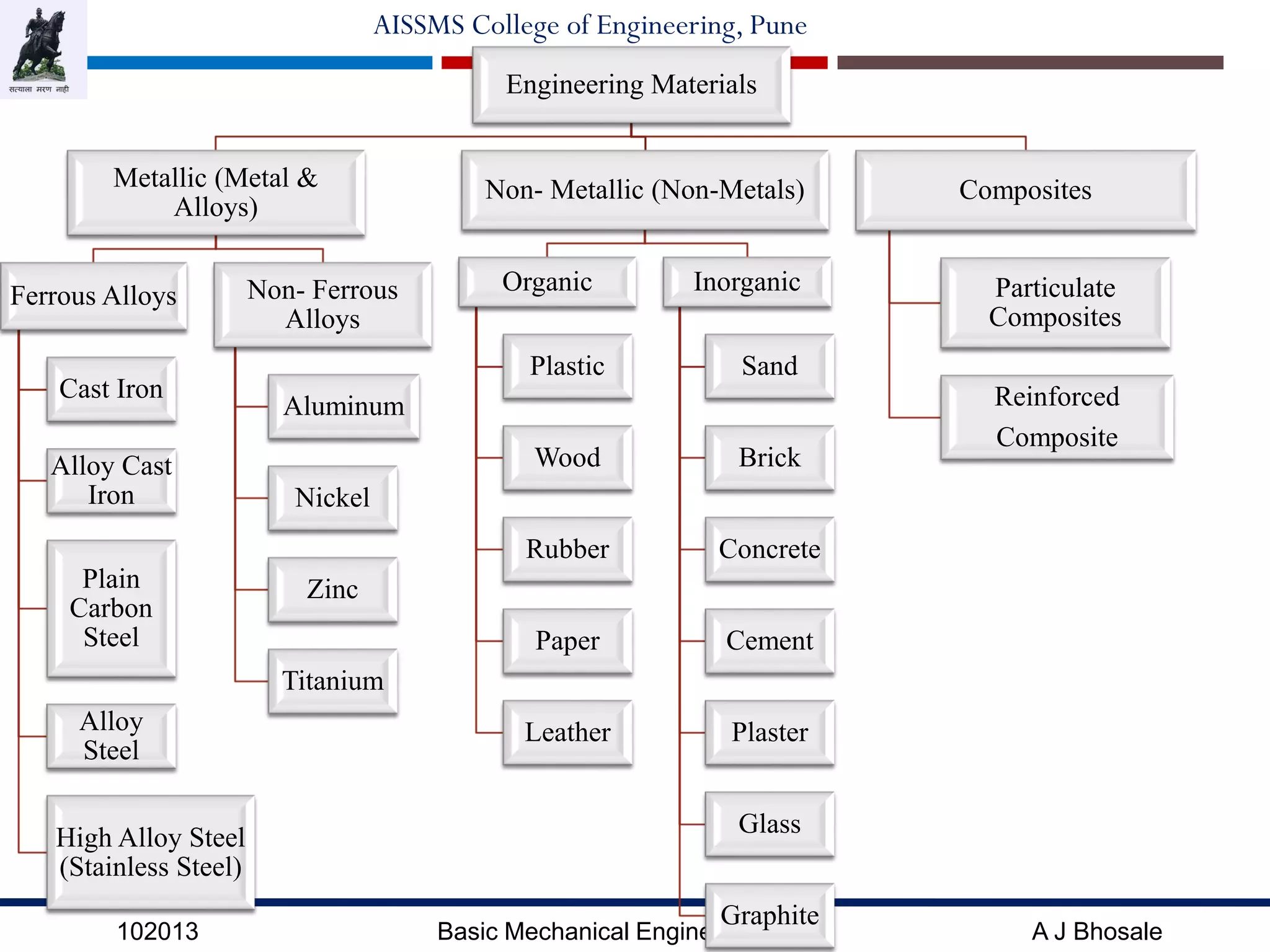

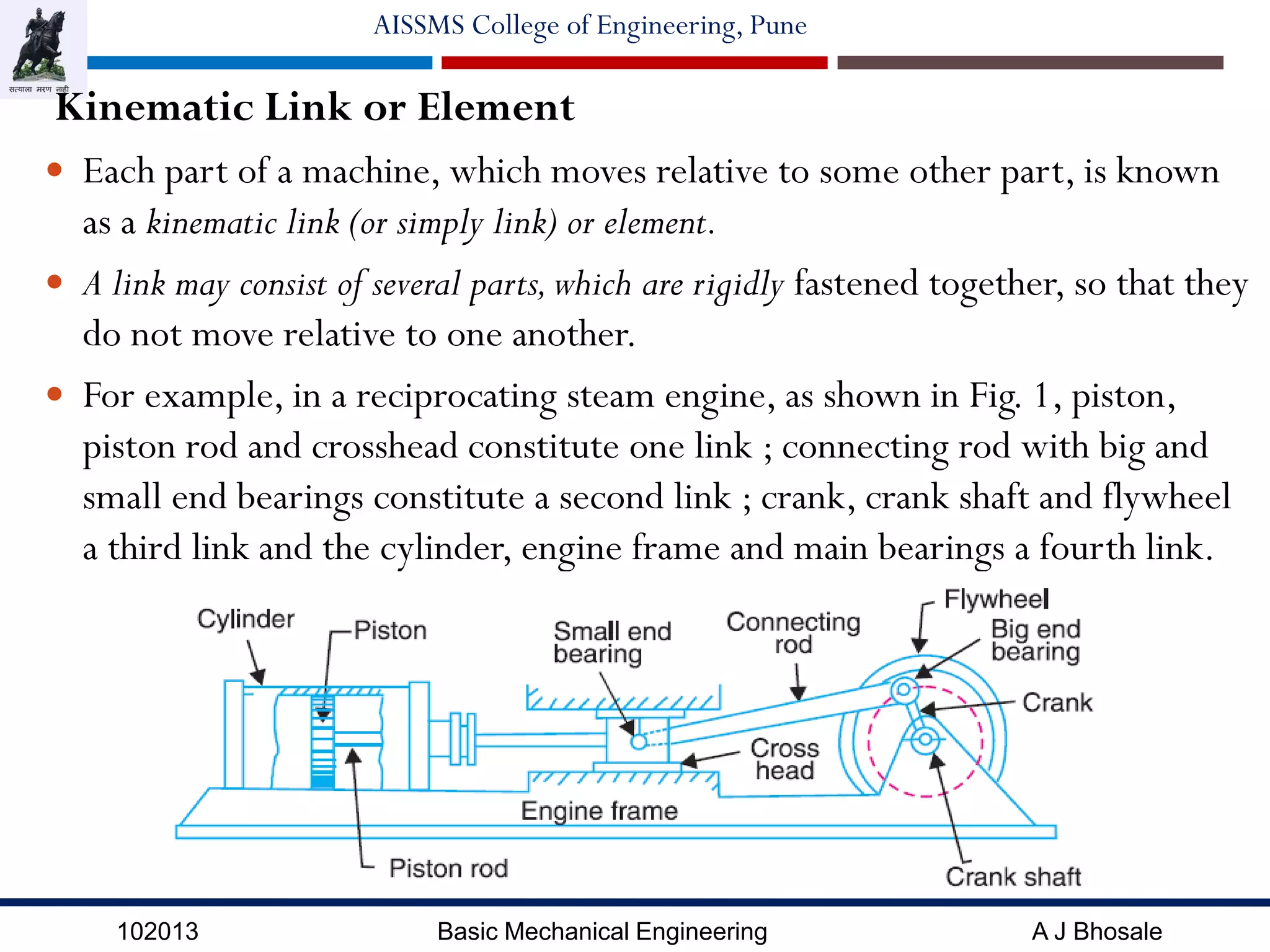

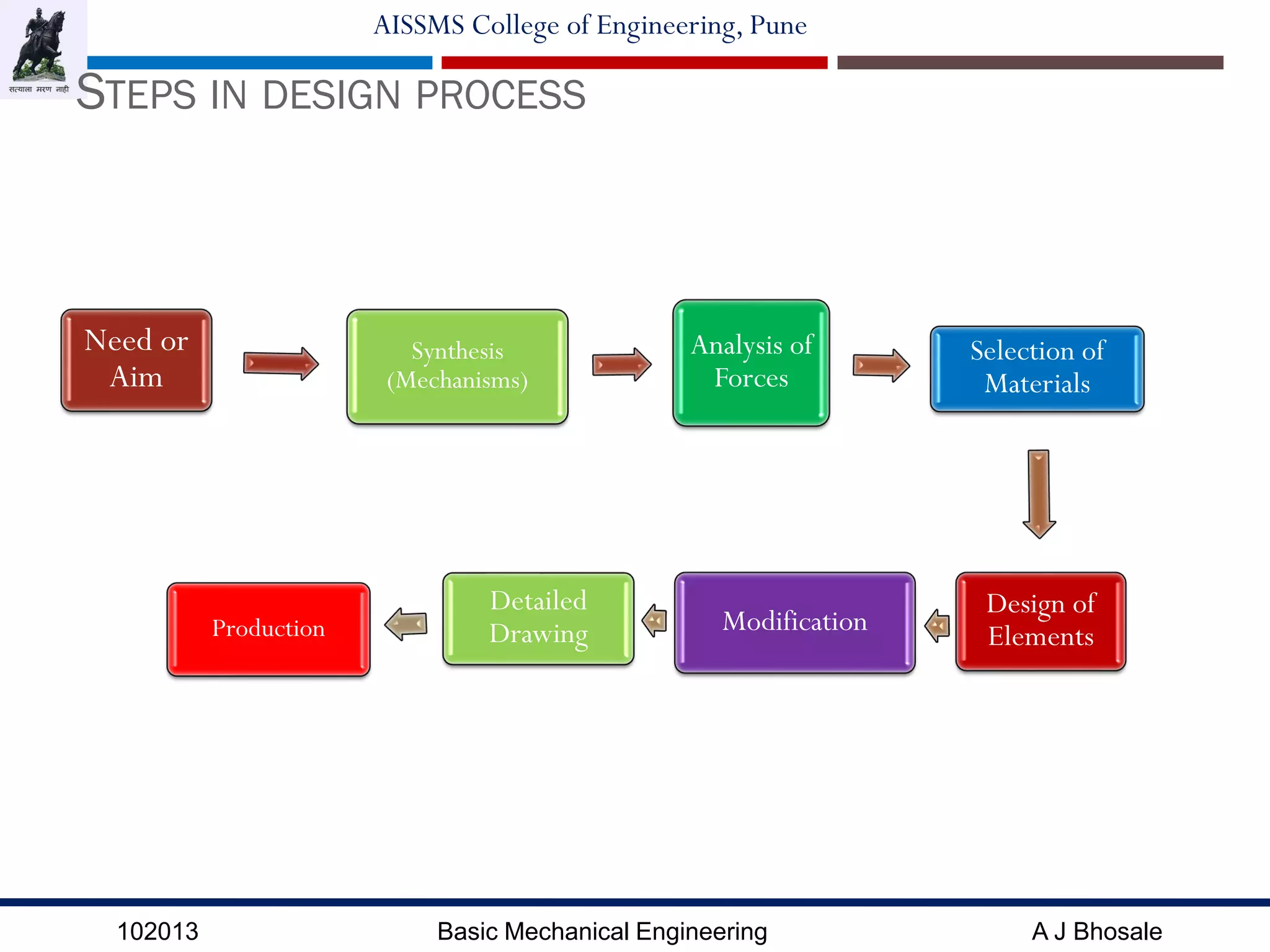

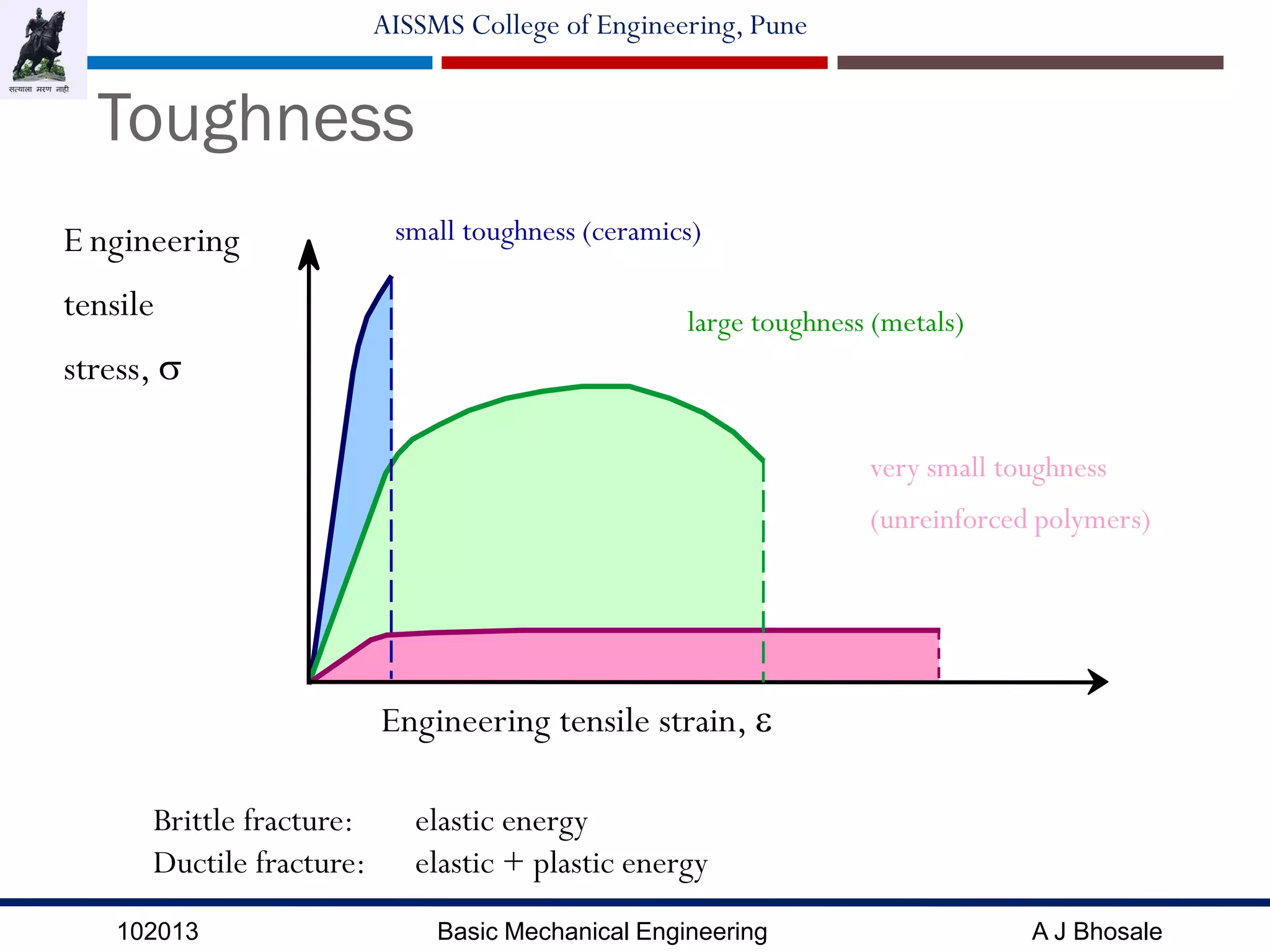

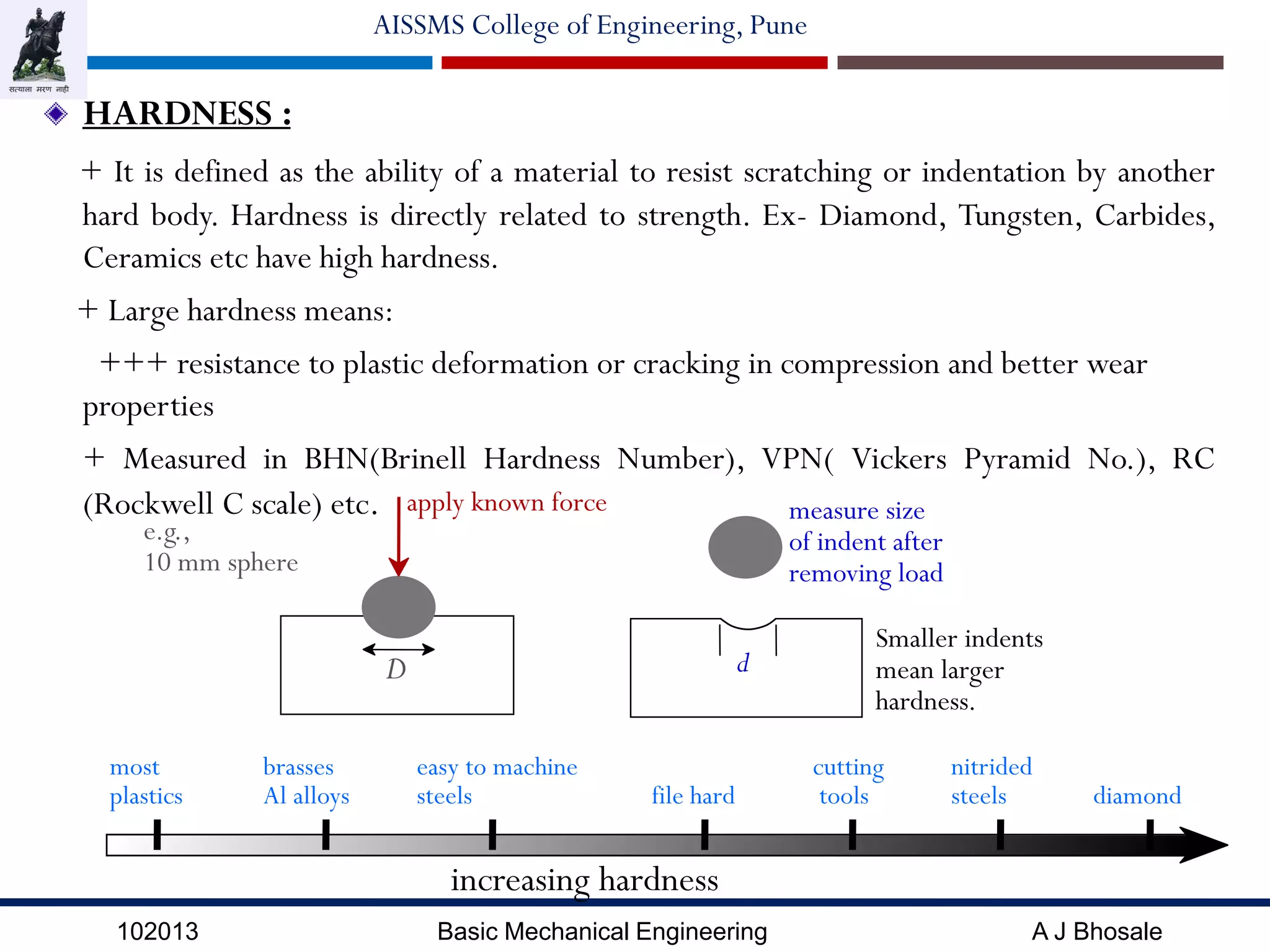

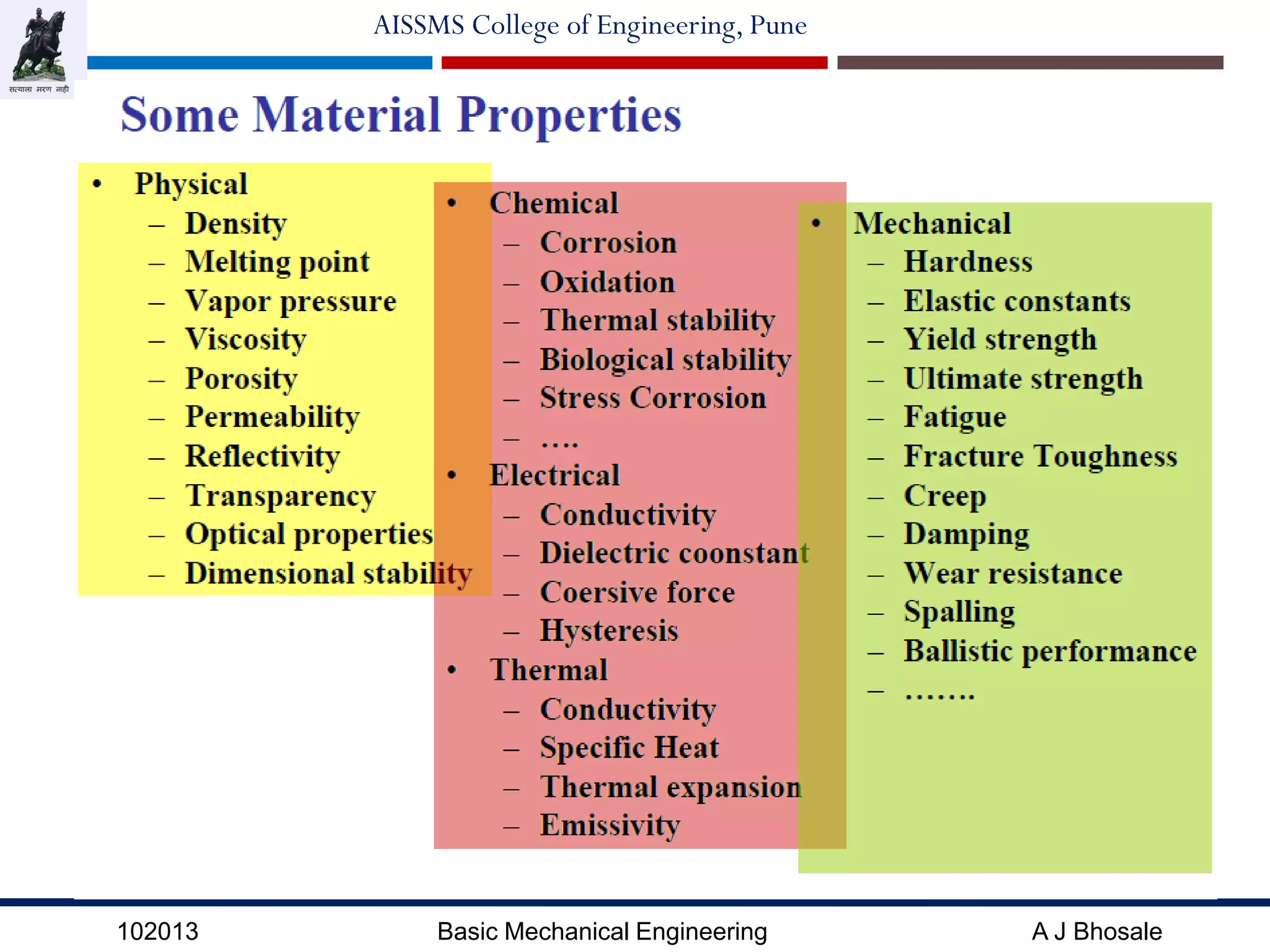

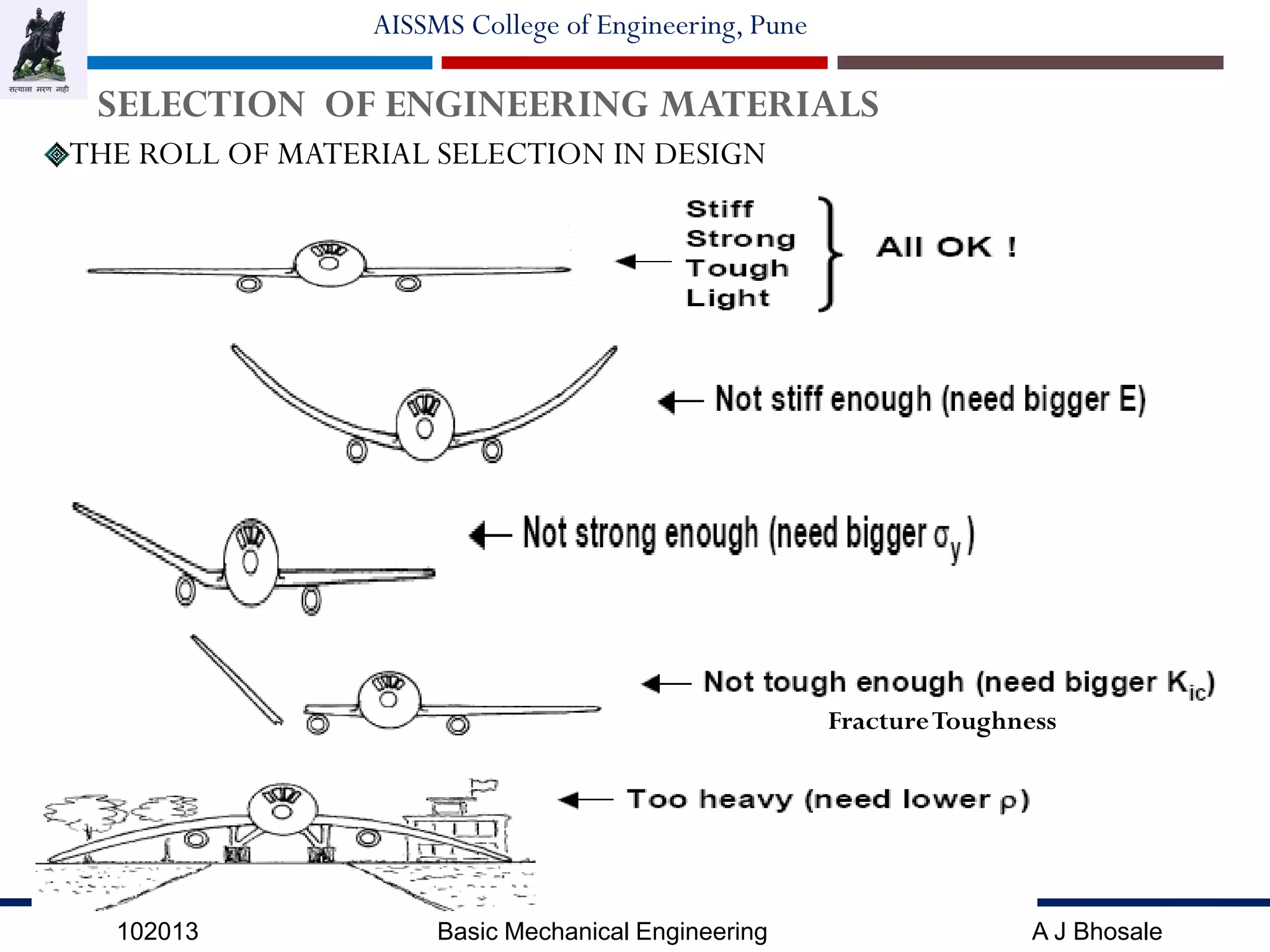

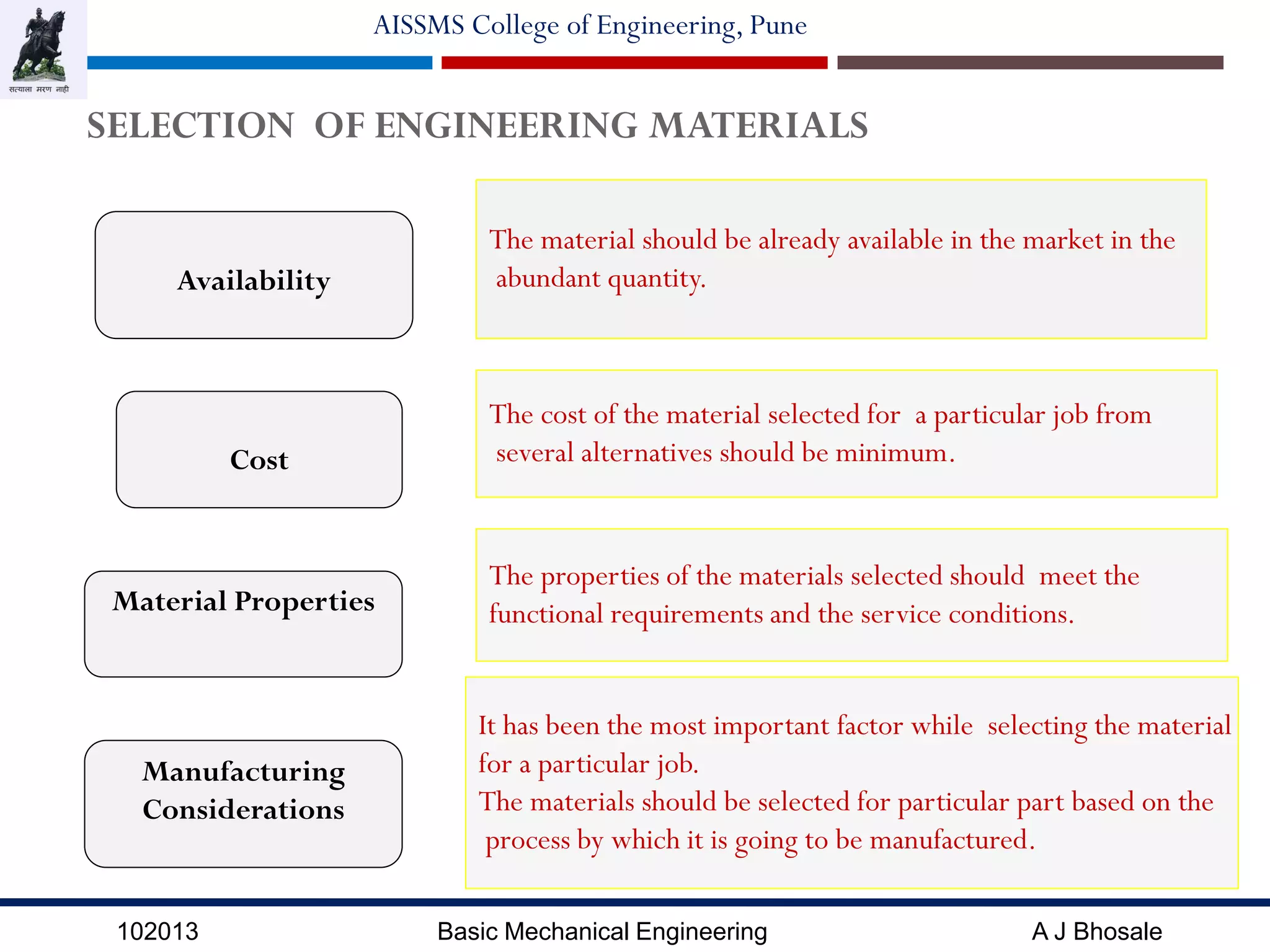

The document outlines the design fundamentals in mechanical engineering, detailing the steps in the design process, which includes defining problems, selecting mechanisms, analyzing forces, and choosing materials. It discusses various design types such as adaptive, developmental, and new design, as well as the mechanical properties of materials like strength, hardness, ductility, and toughness. Additionally, it emphasizes the importance of material selection based on cost, availability, and performance for specific engineering applications.

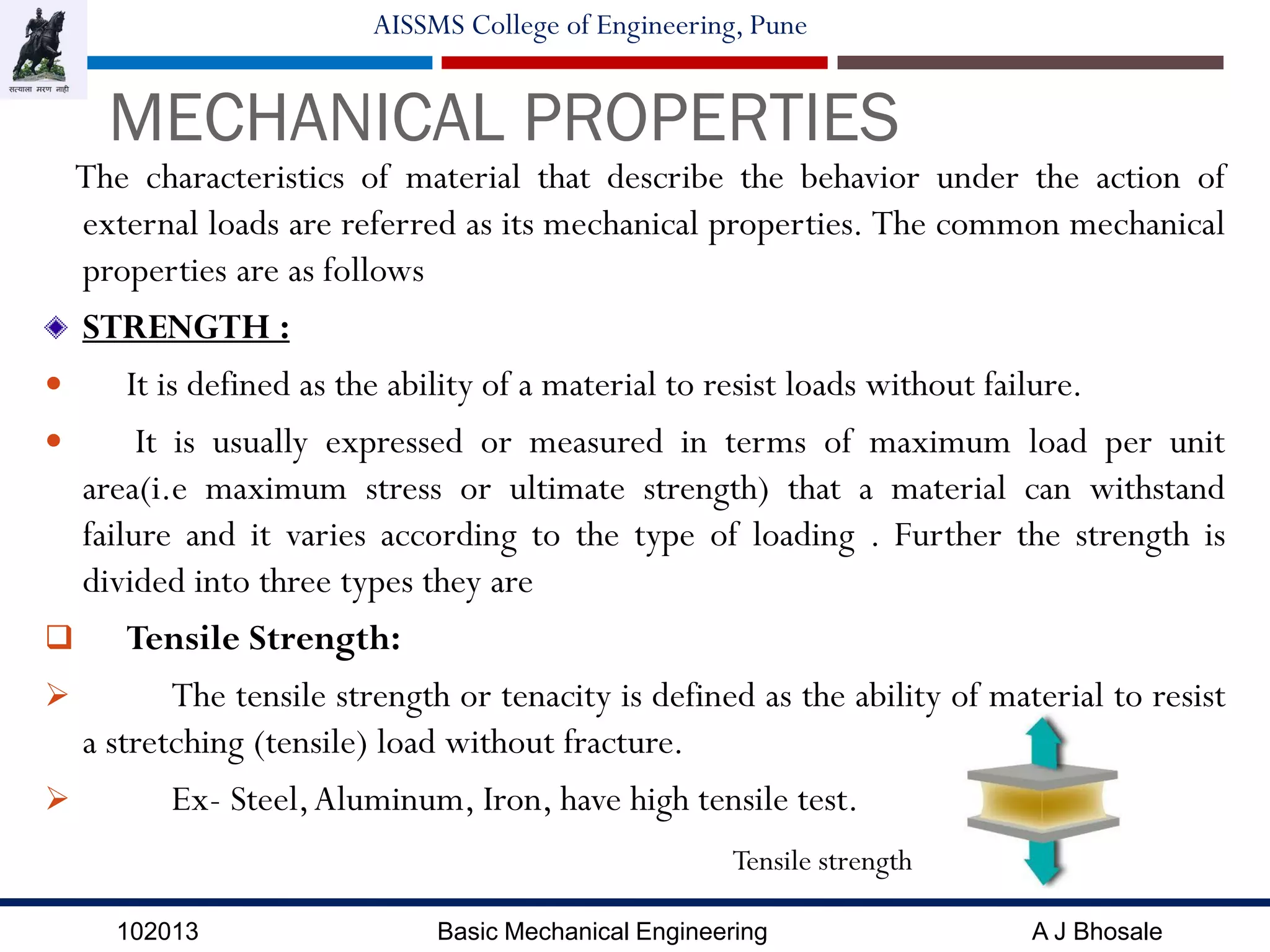

![102013 Basic Mechanical Engineering A J Bhosale

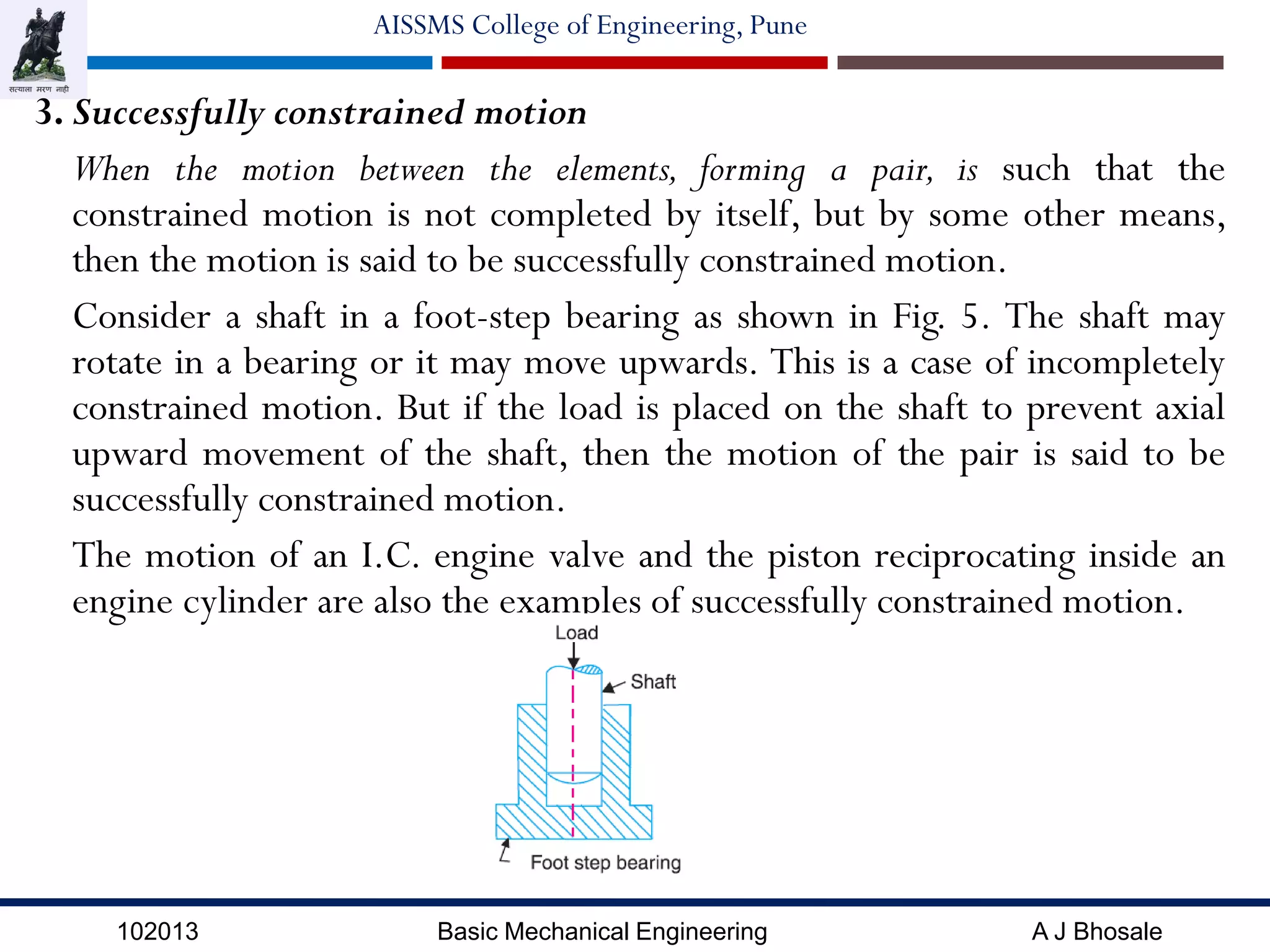

AISSMS College of Engineering, Pune

The effect of environmental conditions [Like temperature,

humidity, etc.] should be given more attention during

selection of material.

Environmental

Considerations

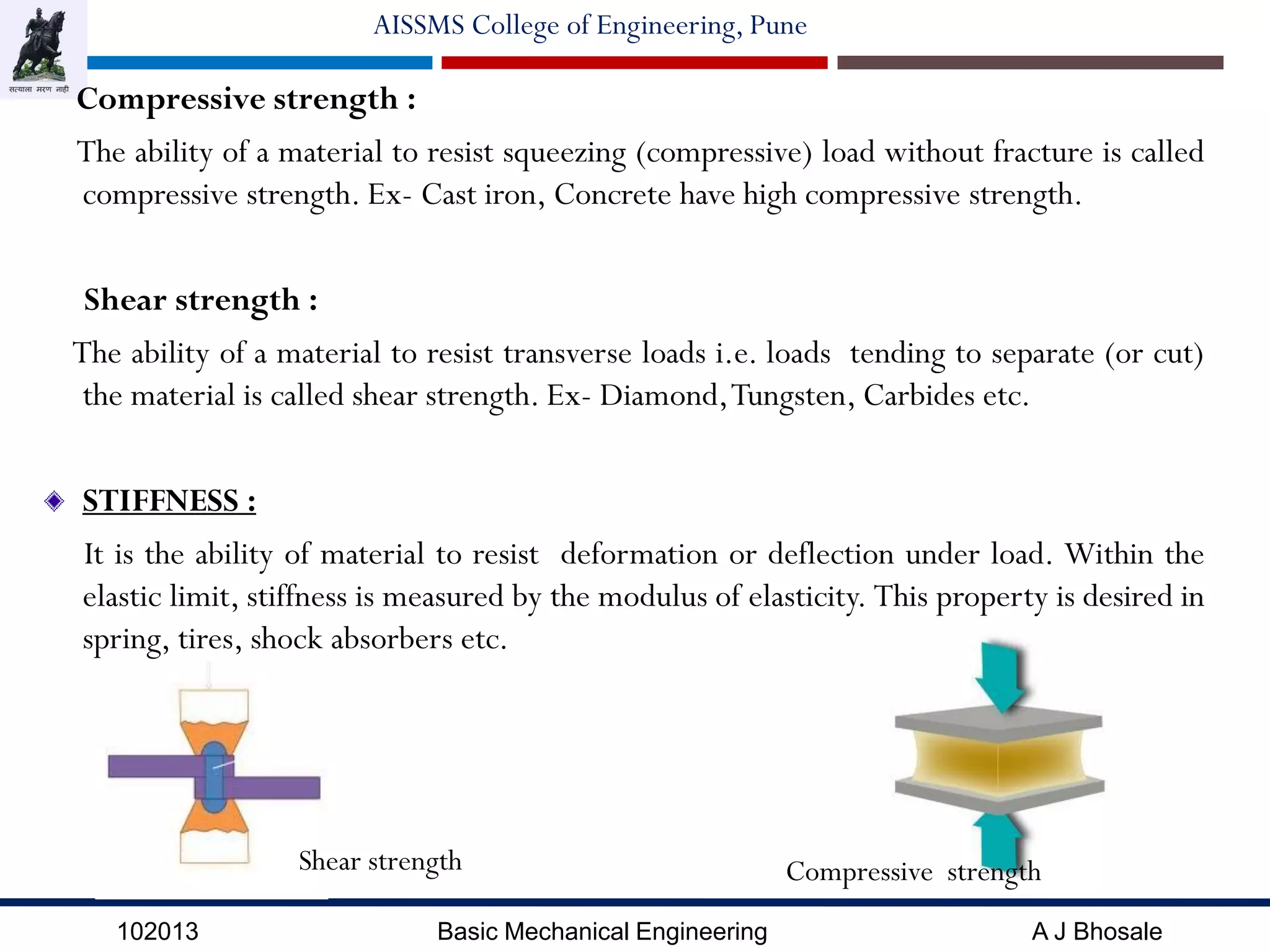

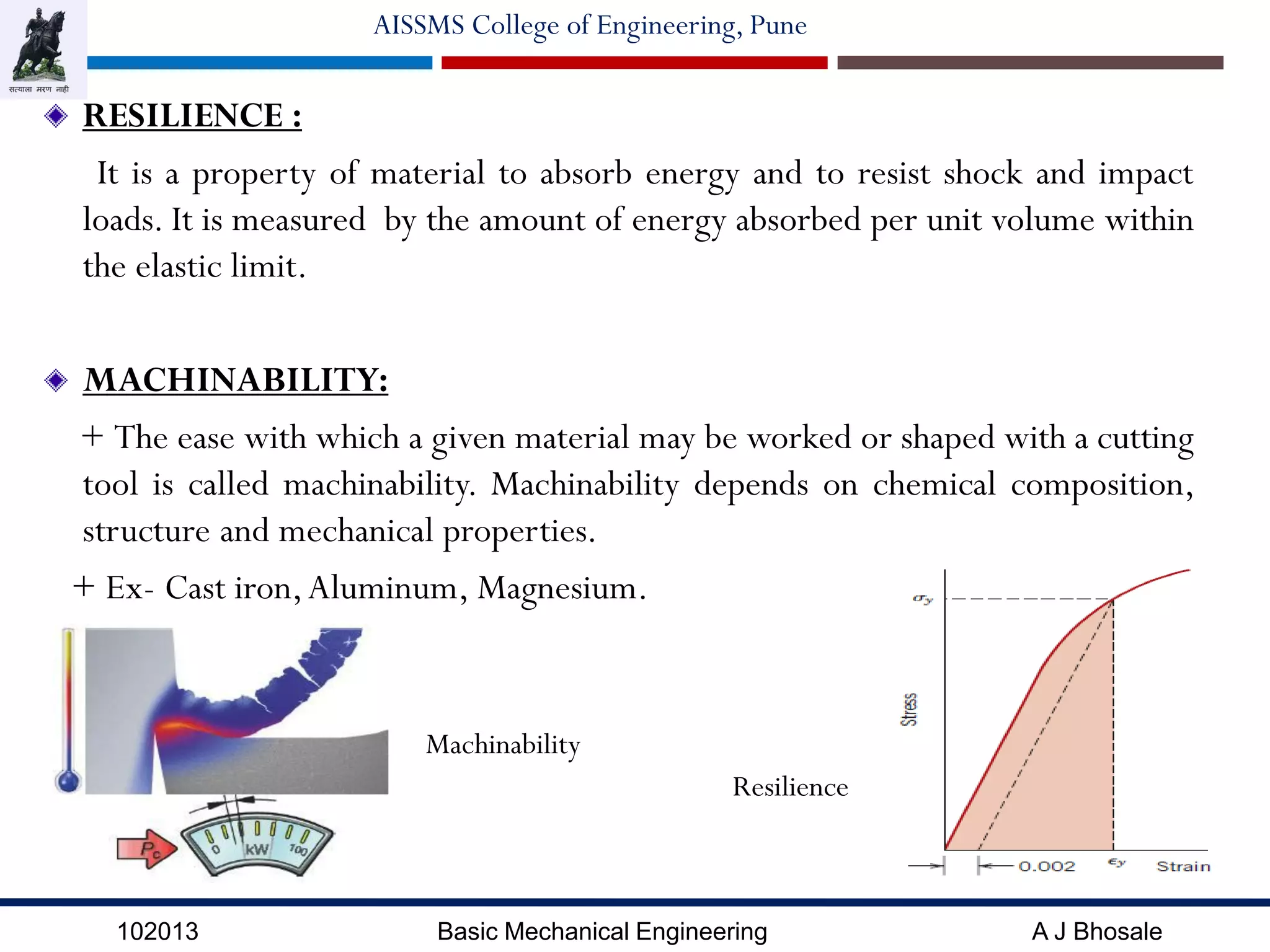

Machinability is the case with which a given metal can be

machined. Machinability of the material depends upon hardness,

strength and chemical Composition of materials.

Machinability

Formability

It is an indication of suitability of the metal for a machine part

that requires forming. Forming depends upon ductility and tensile

Strength.](https://image.slidesharecdn.com/chapter2-170206072506/75/Design-Fundamentals-31-2048.jpg)