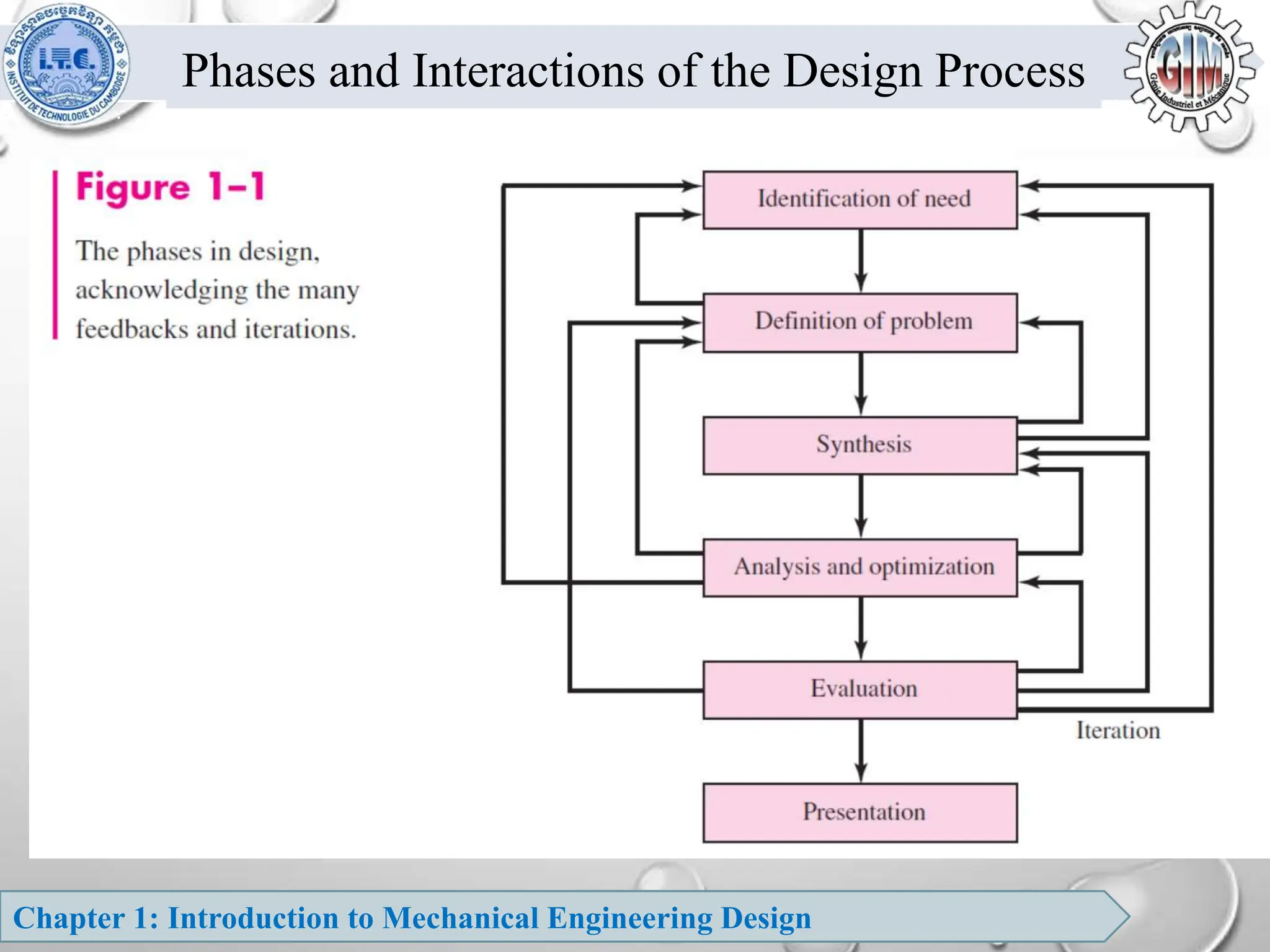

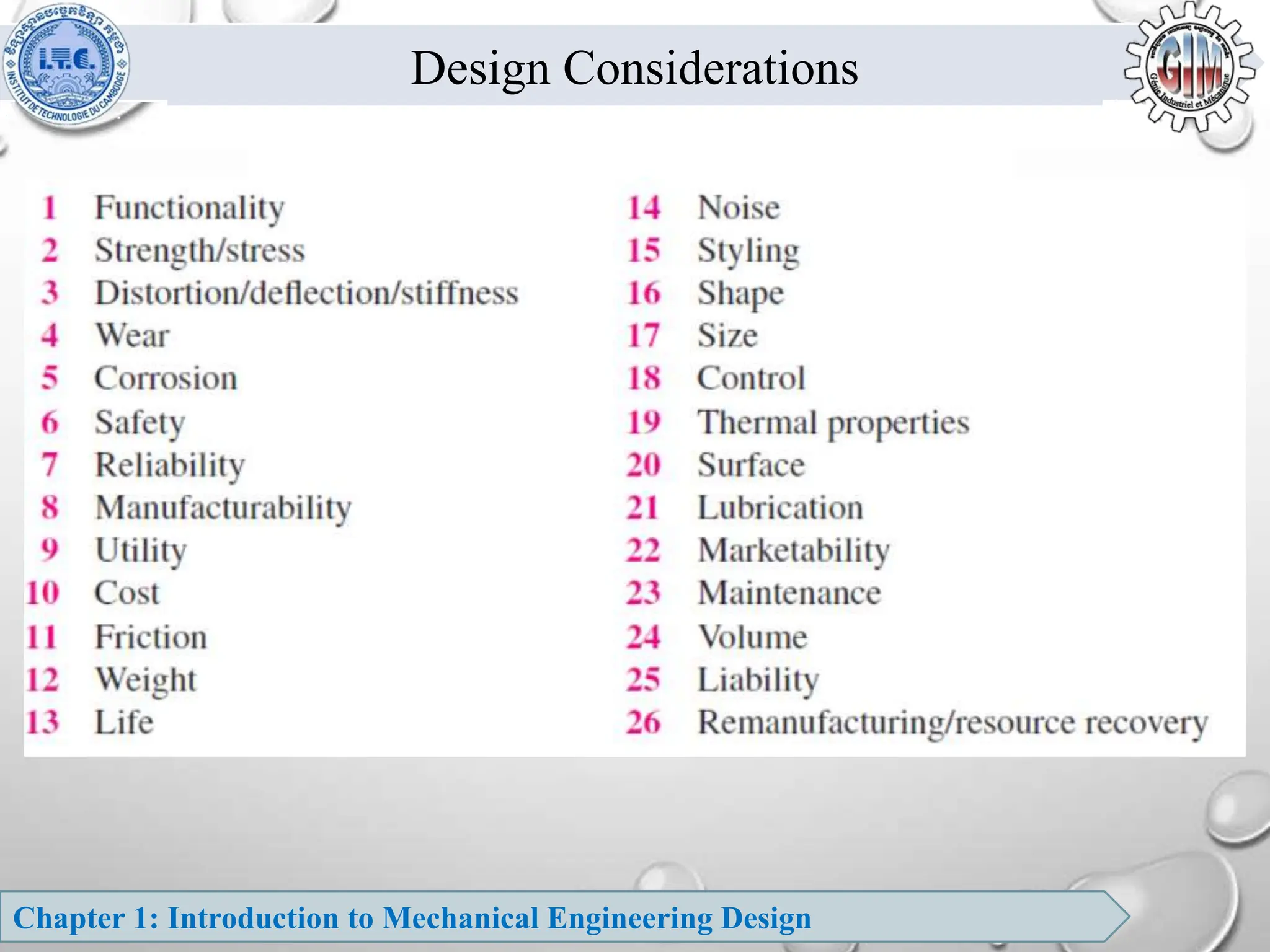

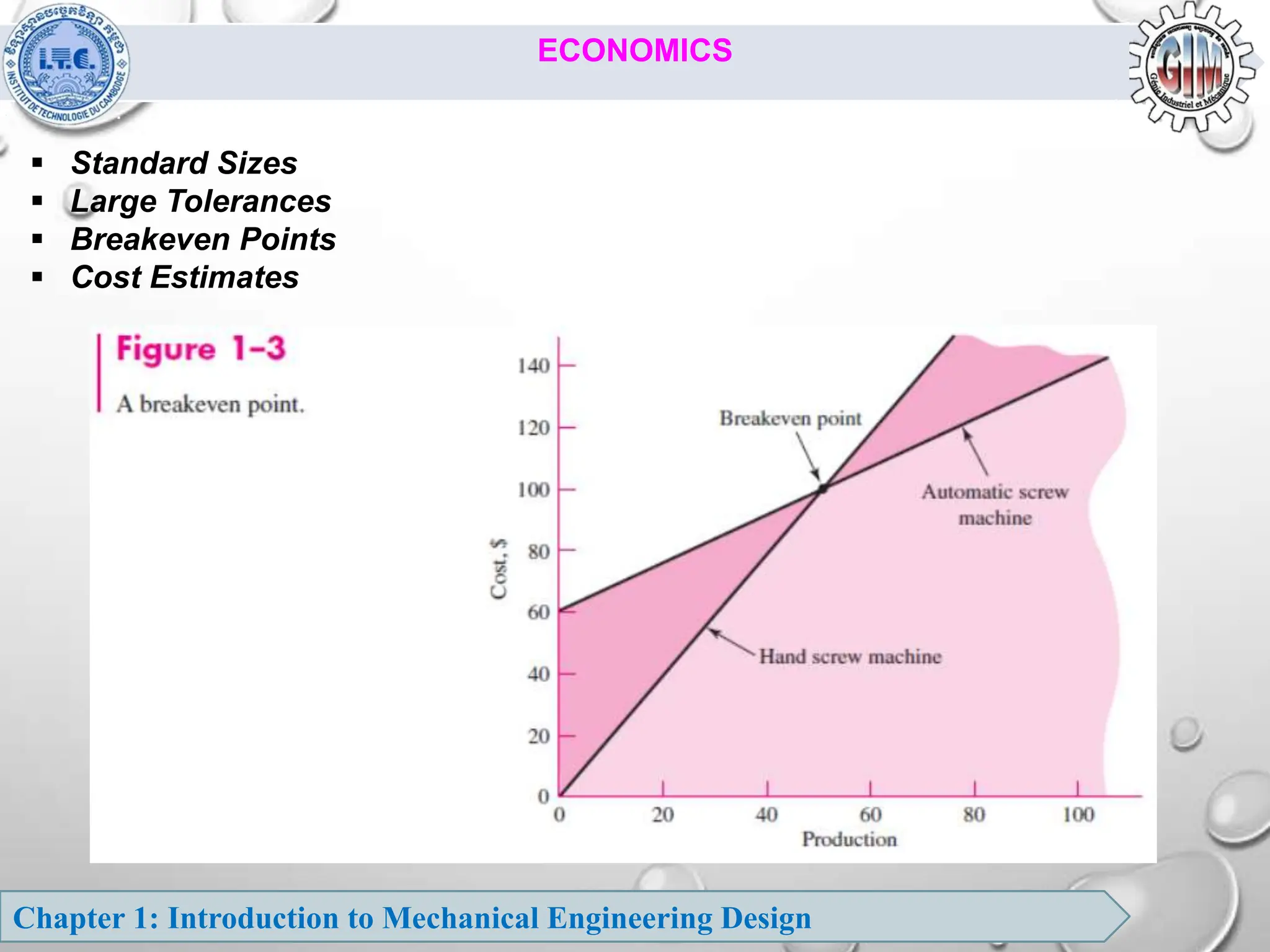

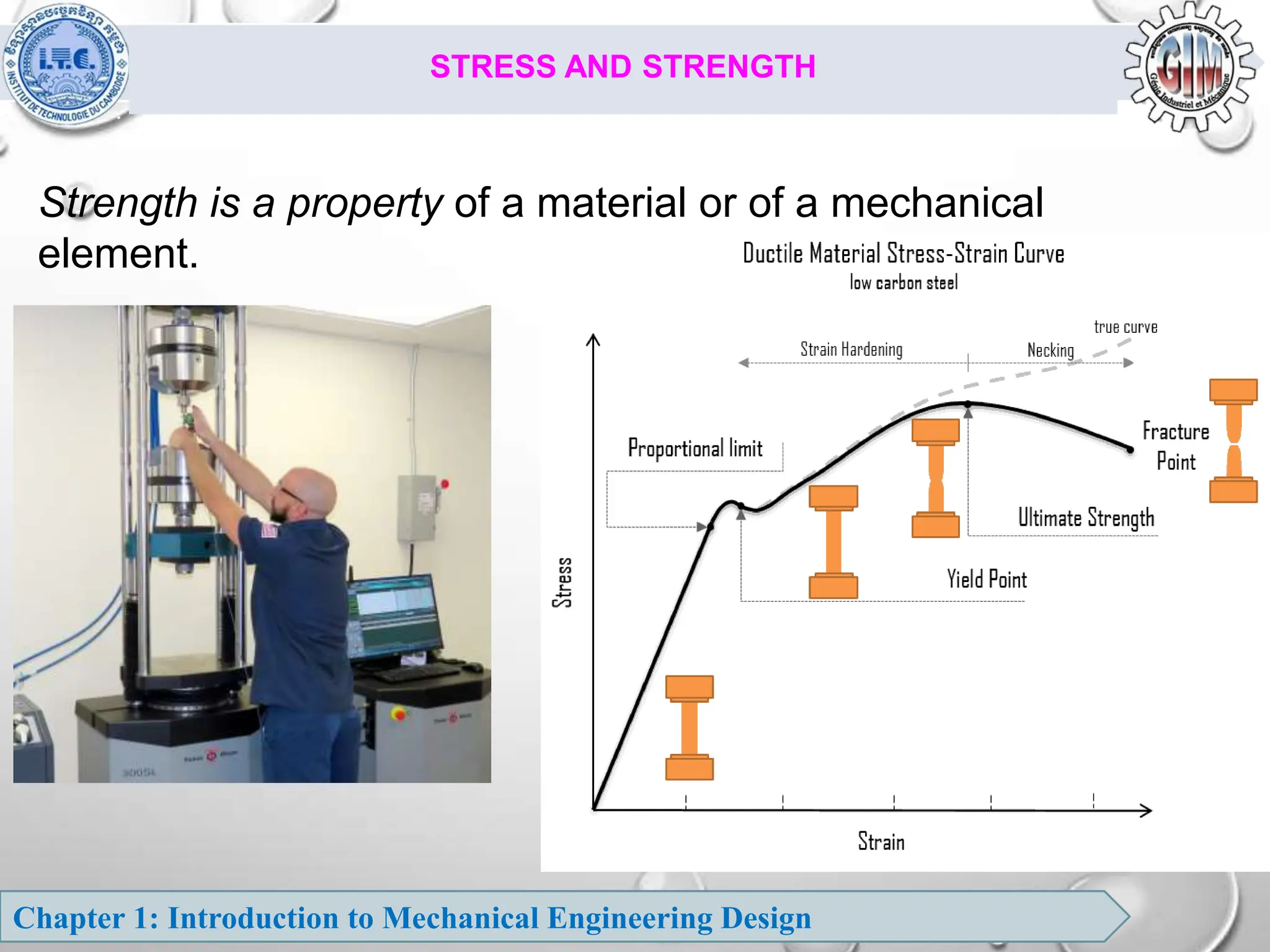

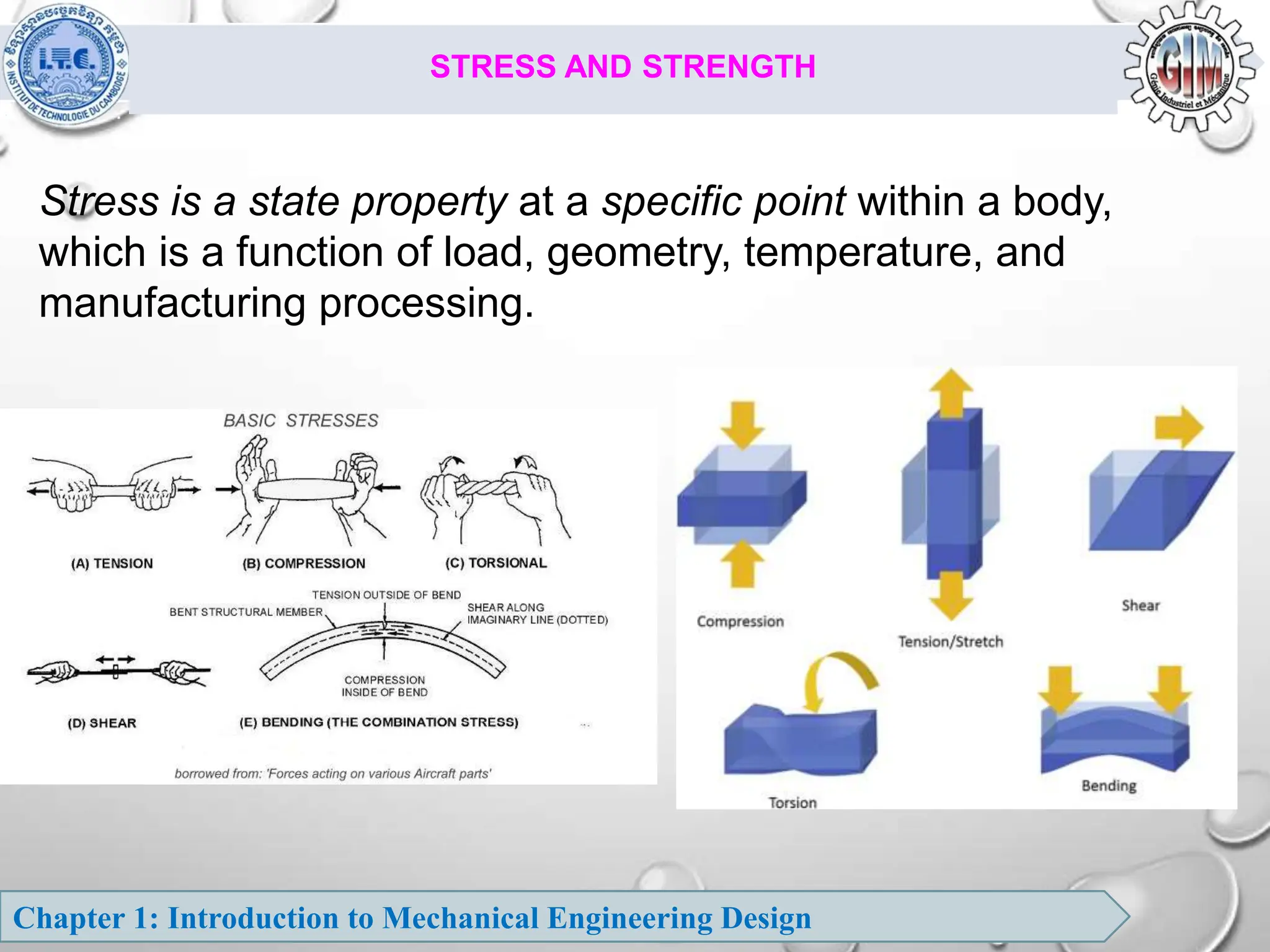

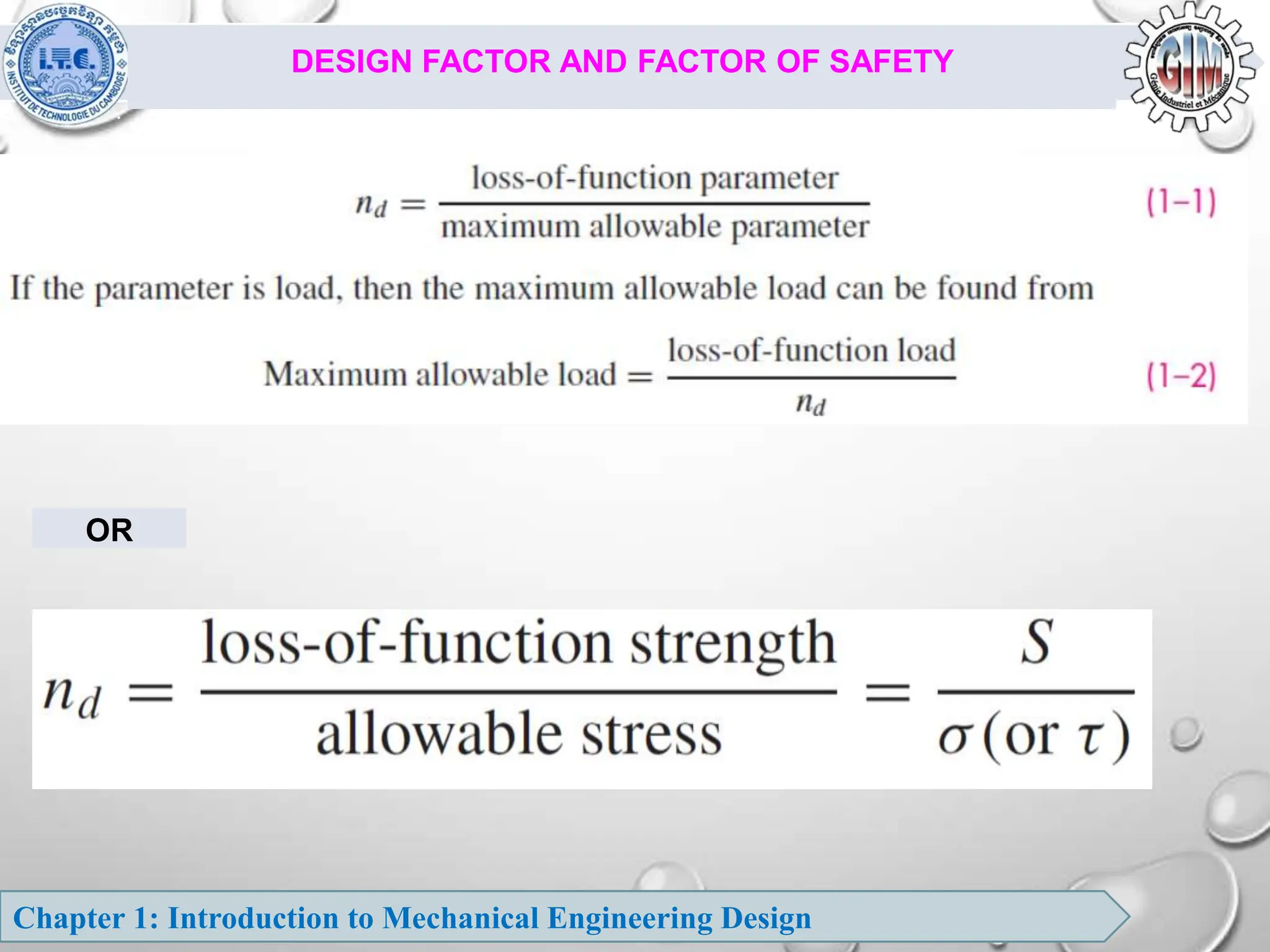

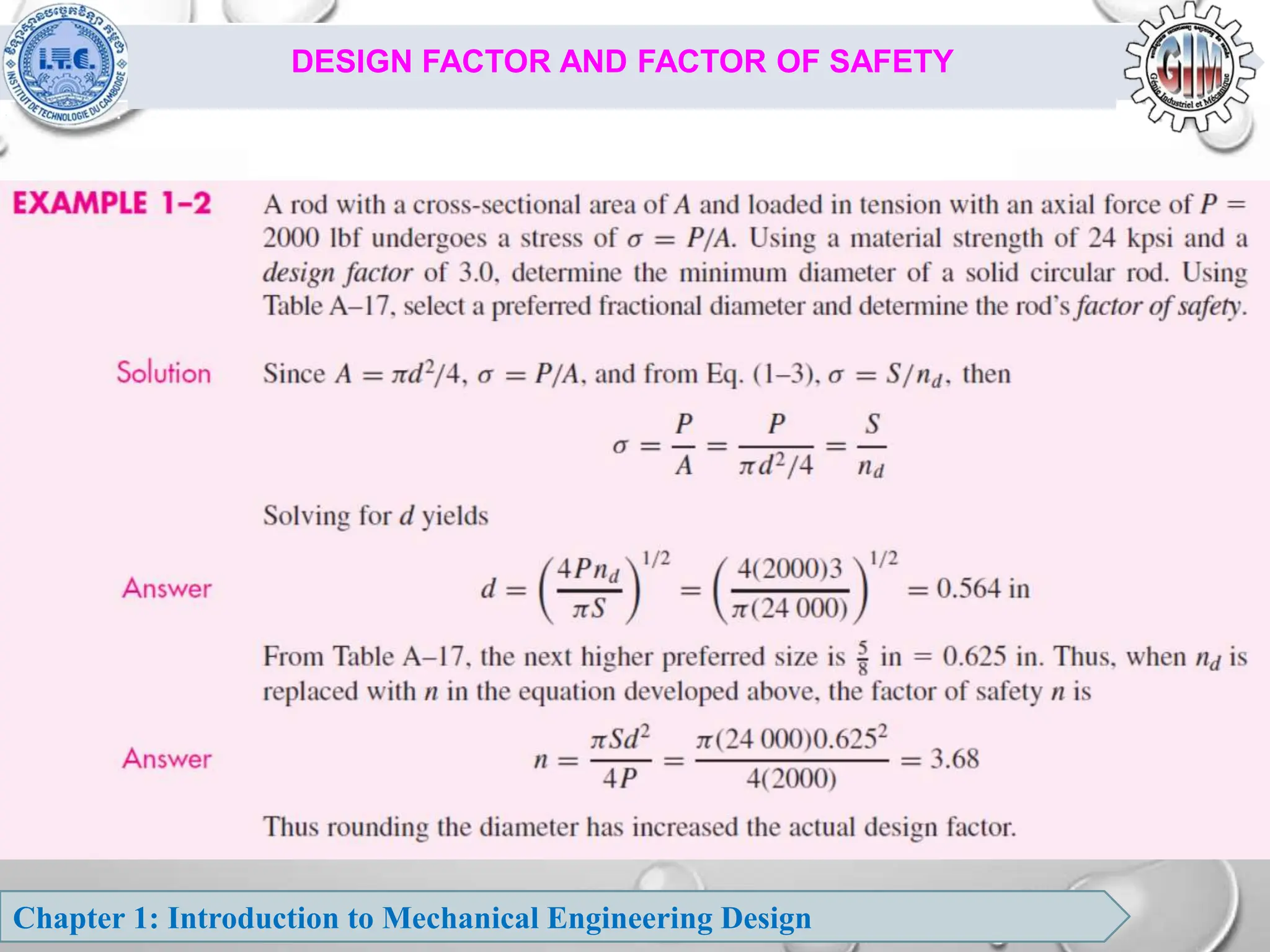

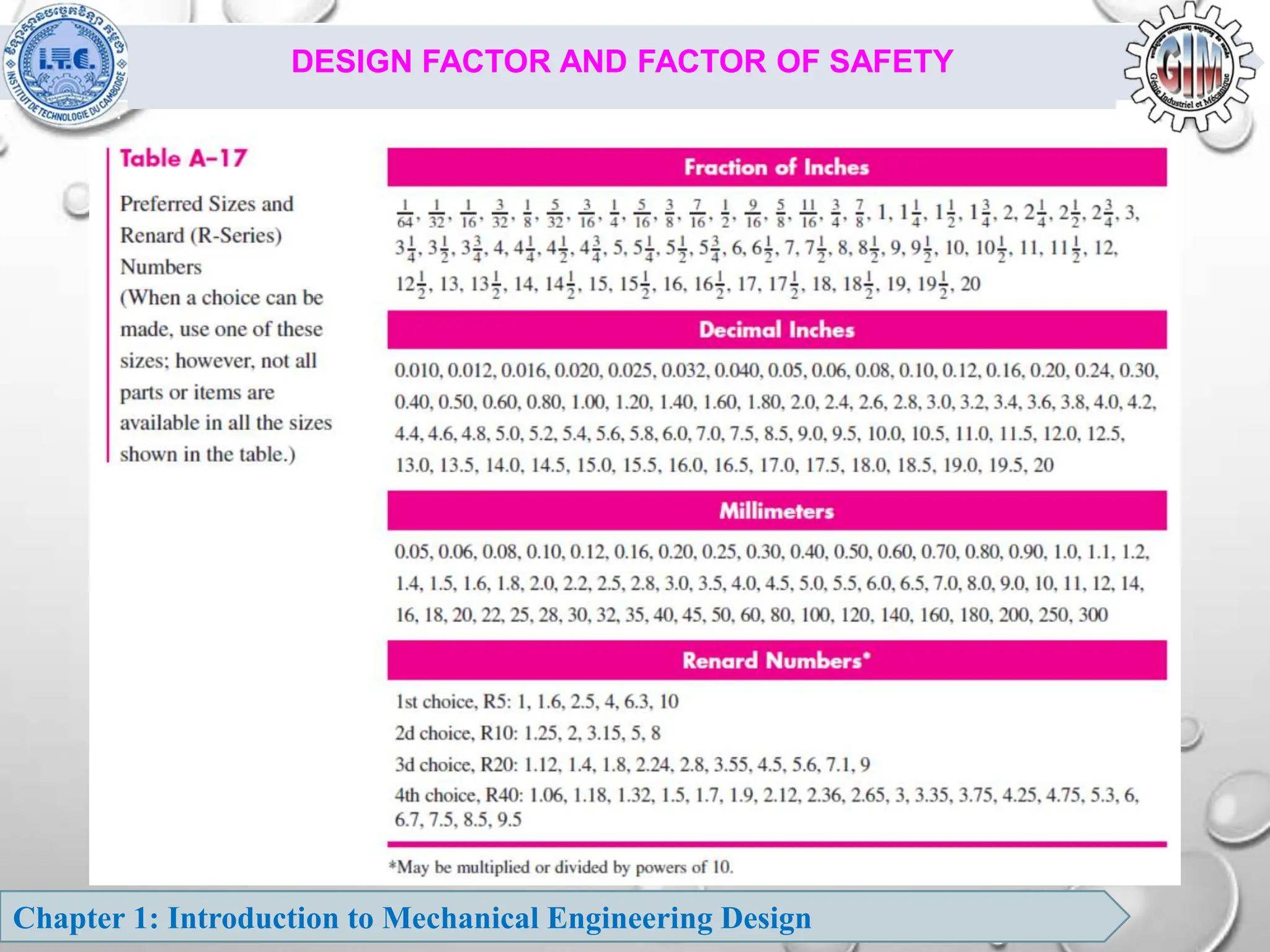

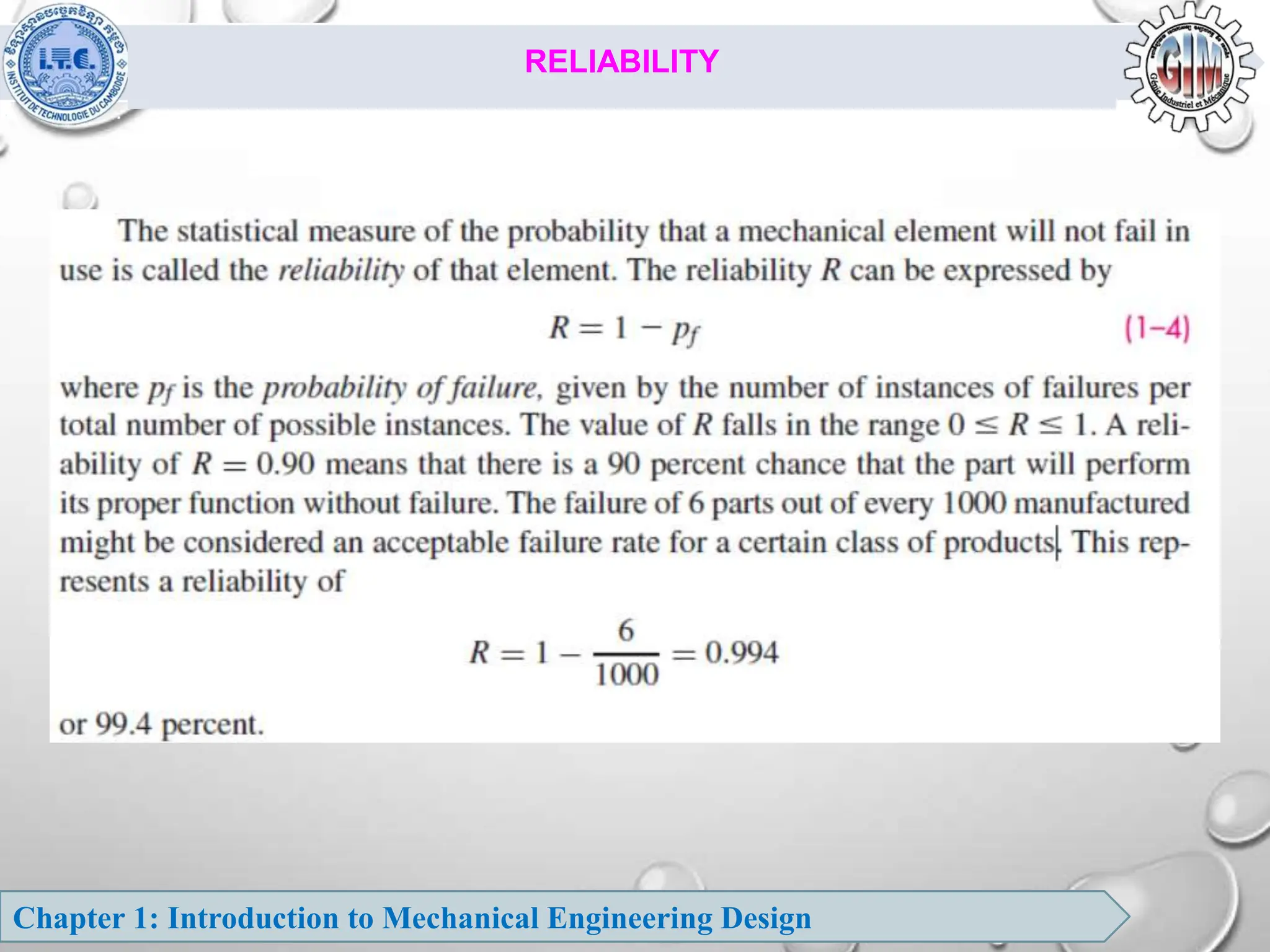

Chapter 1 introduces mechanical engineering design, outlining its iterative and communication-intensive nature, while emphasizing the importance of functionality, safety, and reliability. It discusses the phases of the design process, design tools such as CAD software, and the responsibilities of design engineers regarding standards, codes, and economics. Key concepts such as stress, strength, uncertainties, design factors, and tolerances are also highlighted as essential considerations in the engineering design process.

![[CHAPTER 1: INTRODUCTION TO MECHANICAL ENGINEERING DESIGN]

GIM-FC 2024

Seab Piseth | pisethseab@gmail.com | 011 70 48 25

Department of Industrial and Mechanical Engineering

Faculty of Electrical Engineering

Institute of Technology of Cambodia

MECHANICAL

CONSTRUCTION](https://image.slidesharecdn.com/chapter1introductiontomechanicalengineeringdesign-240503090259-46b44e25/75/Chapter-1-Introduction-to-Mechanical-Engineering-Design-pptx-1-2048.jpg)