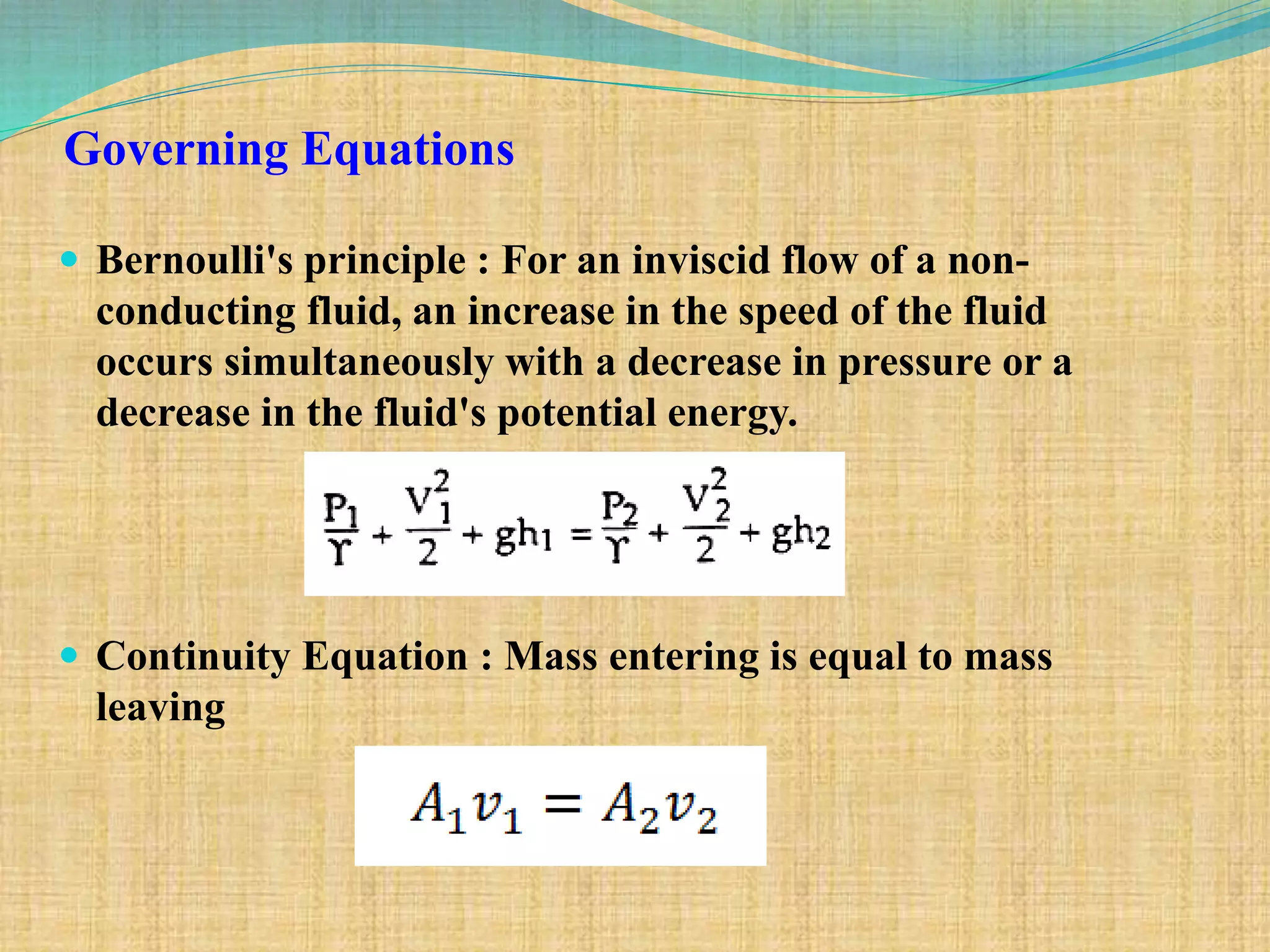

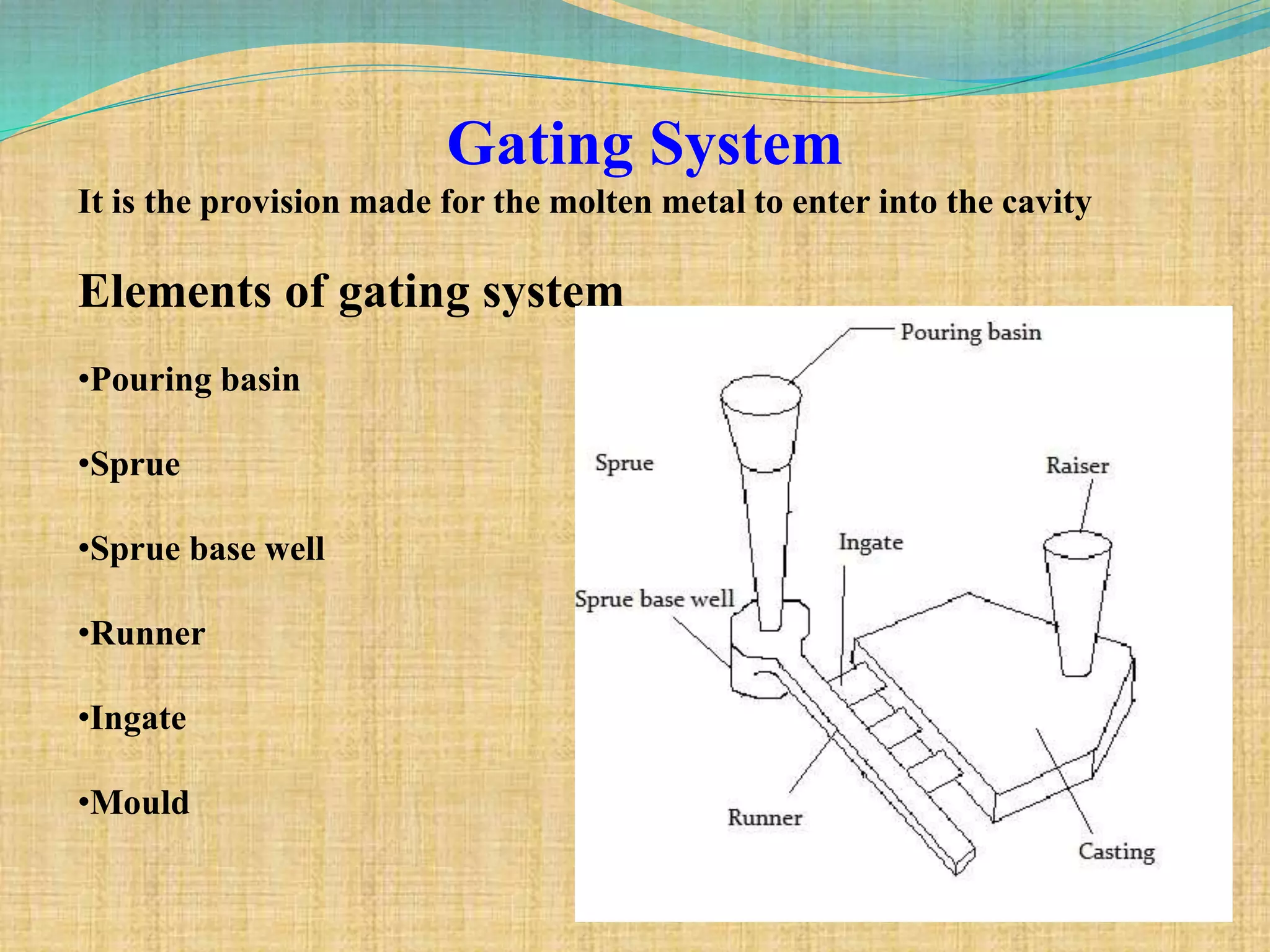

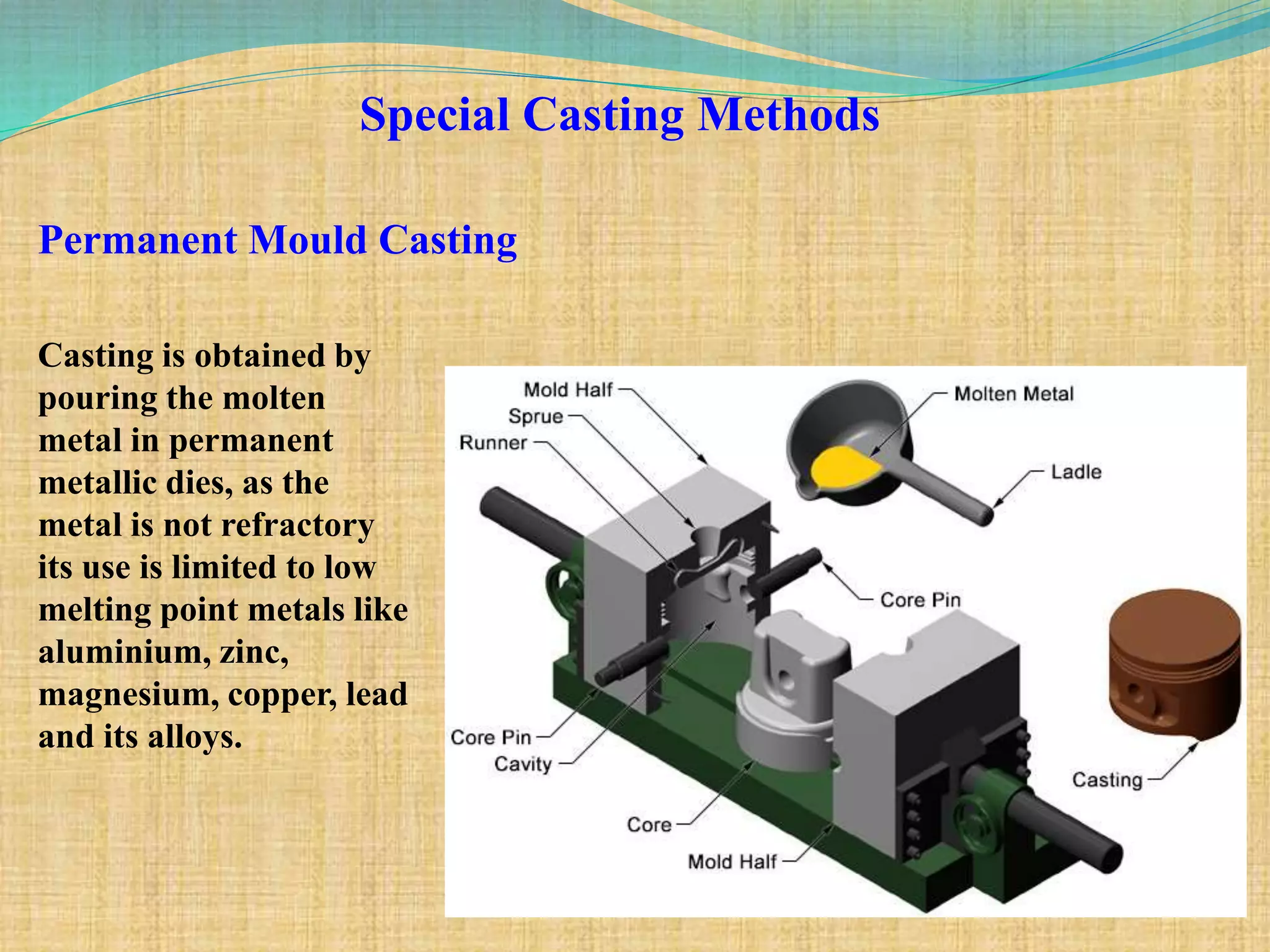

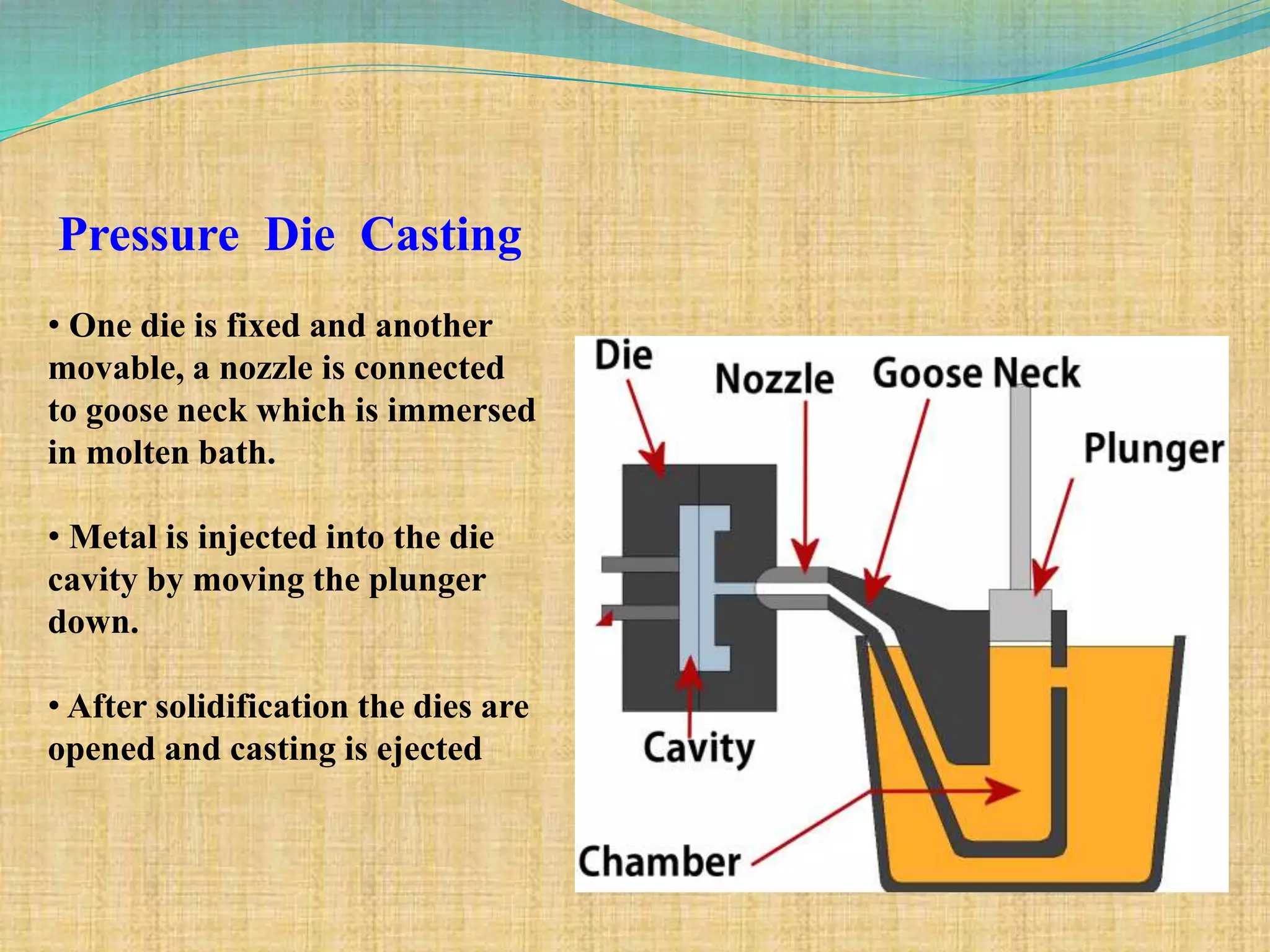

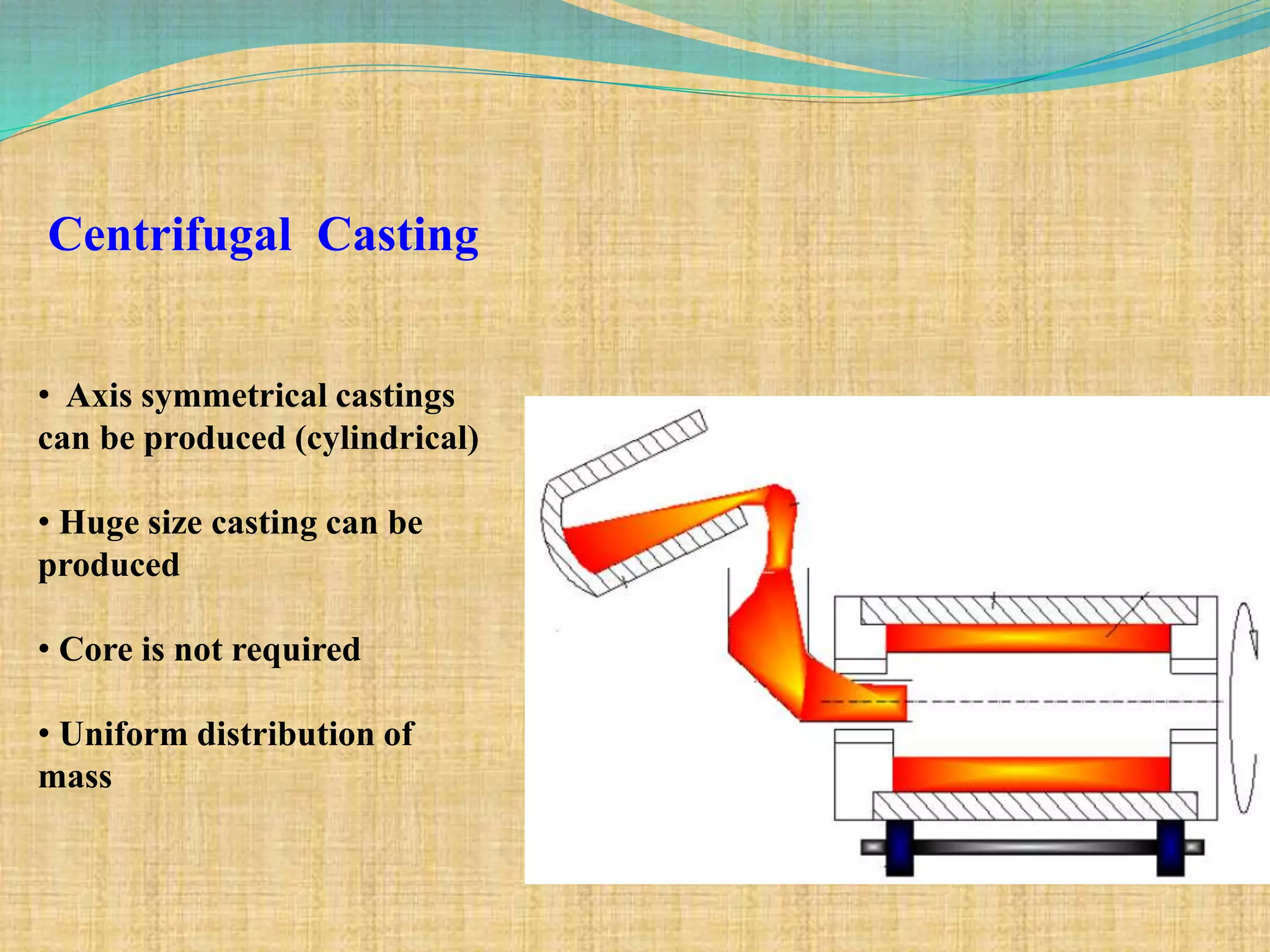

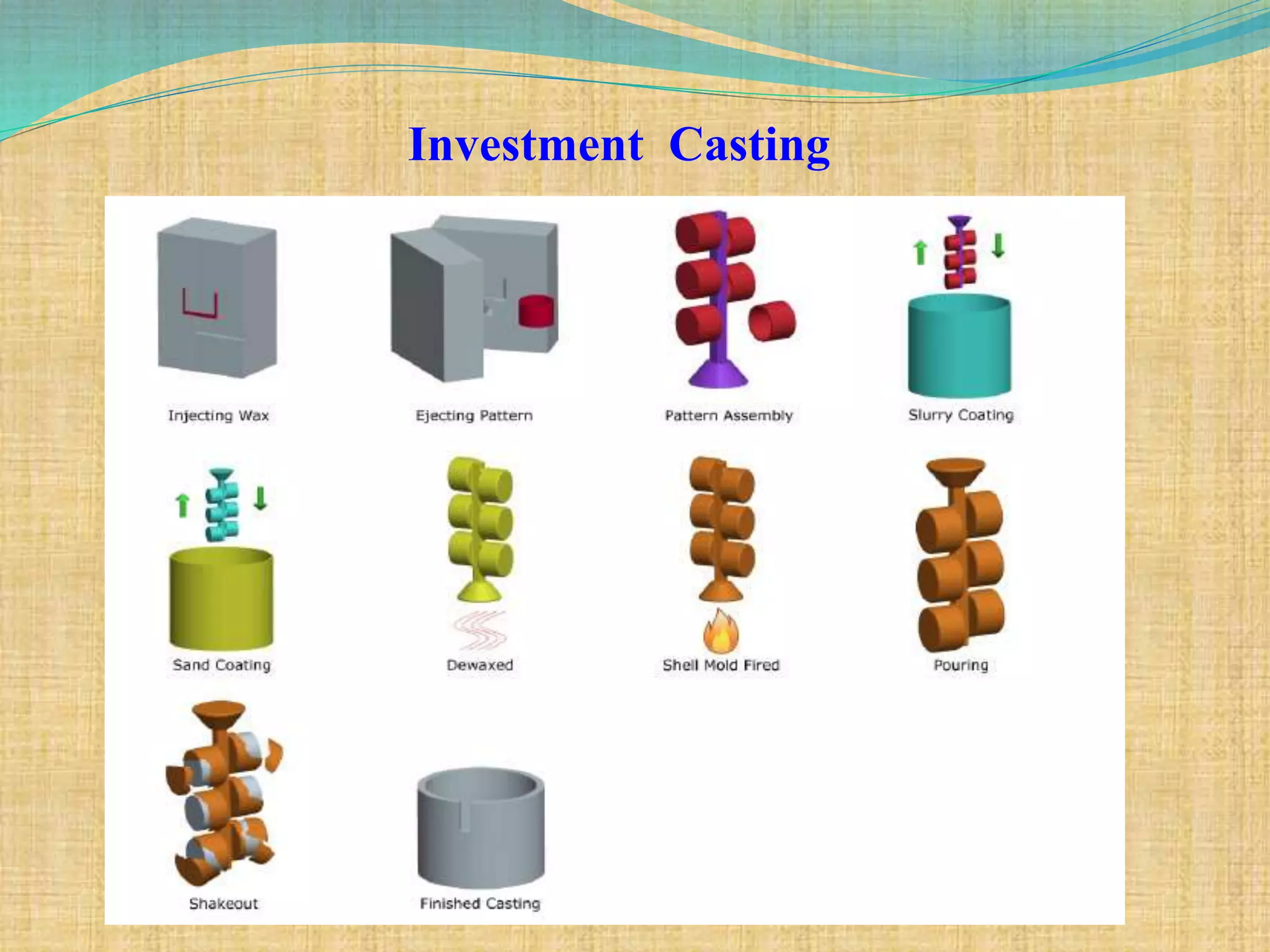

The document discusses casting techniques in engineering, covering its history, need, classification, methods, and defects, as well as inspection processes for castings. It details various casting methods, such as sand casting, pressure die casting, and investment casting, along with their specific properties and applications. Additionally, it highlights common casting defects and inspection methods to ensure quality in the casting process.