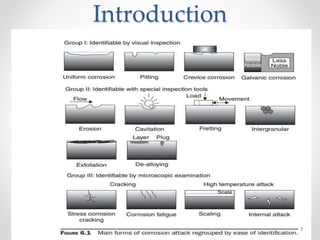

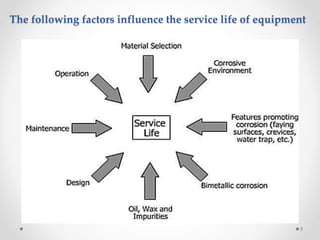

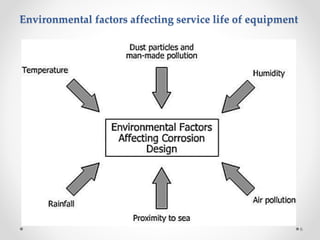

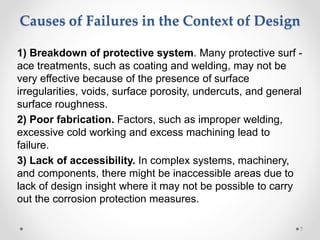

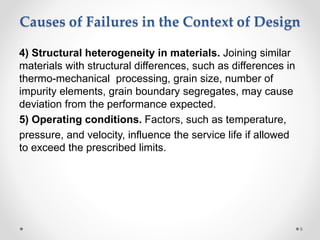

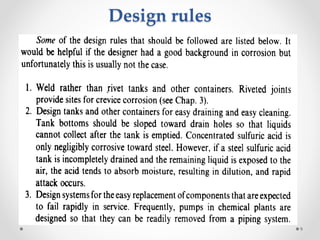

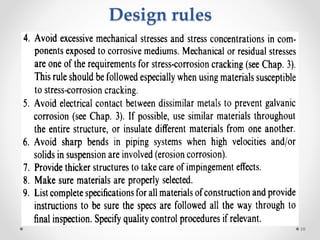

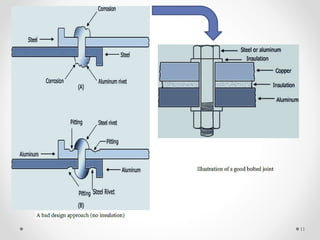

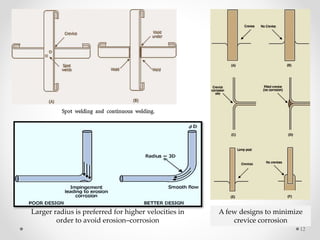

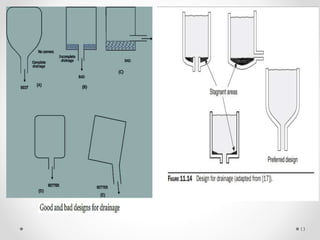

The document discusses the importance of corrosion prevention at the design stage, emphasizing that good design is as cost-effective as a poor one, yet a bad design leads to higher long-term expenses. It outlines several factors influencing equipment service life, including environmental conditions and design flaws, such as inadequate protective systems and poor fabrication. The conclusion suggests that adhering to specific design rules can help minimize issues like crevice corrosion and improve overall component longevity.