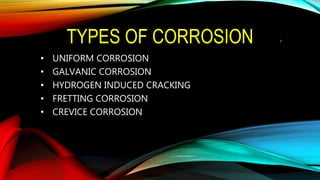

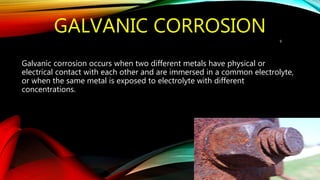

The document discusses corrosion, defining it as the damage to materials due to environmental reactions, highlighting its natural occurrence and preventability. It outlines various types of corrosion, their consequences on industries such as petroleum and construction, and the financial losses incurred. Prevention strategies are emphasized, including material selection, proper design, protective methods, and maintenance.