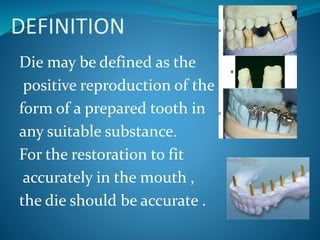

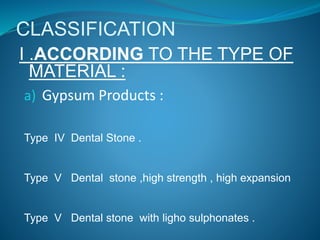

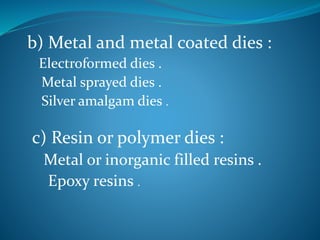

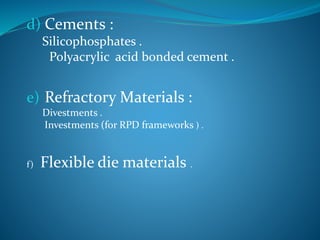

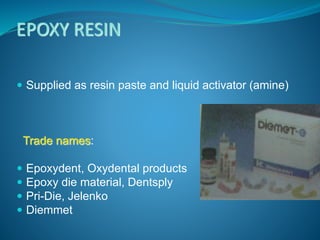

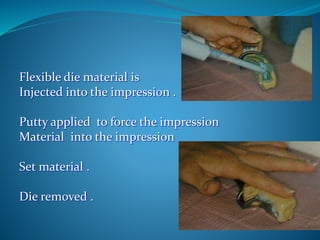

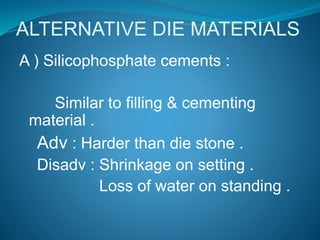

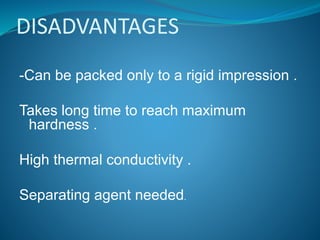

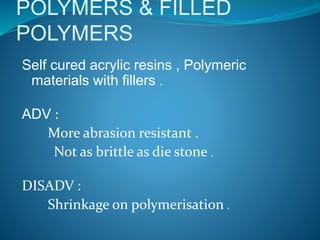

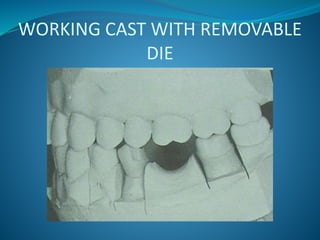

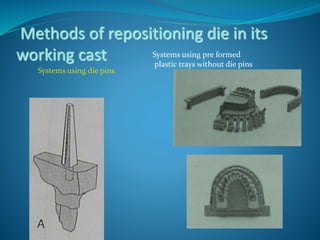

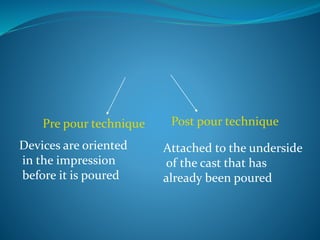

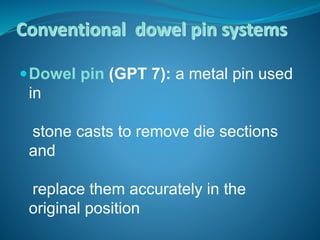

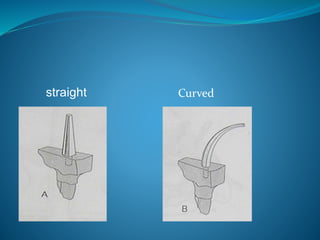

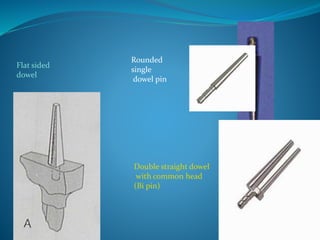

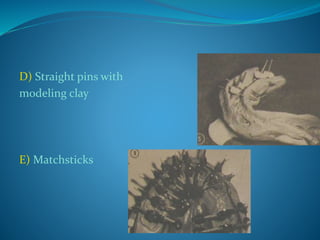

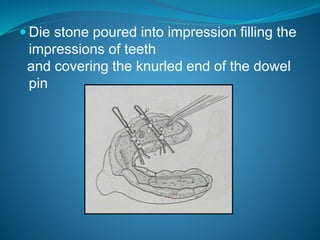

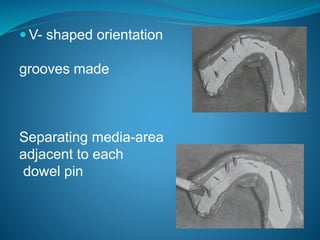

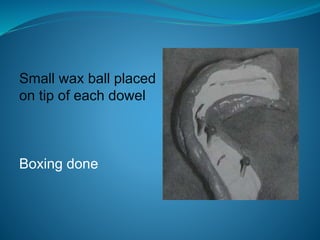

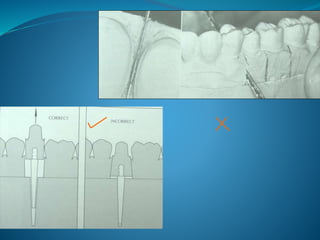

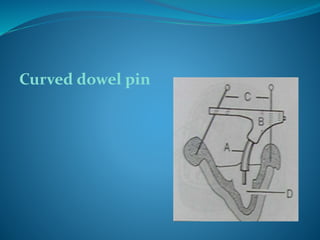

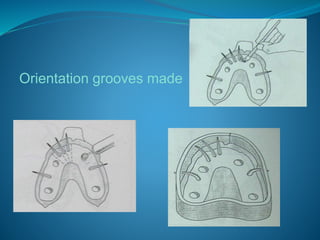

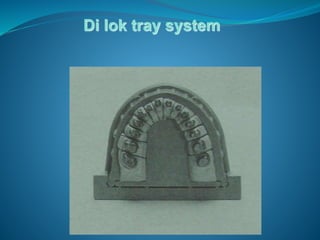

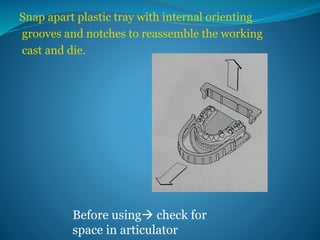

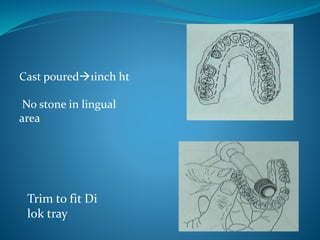

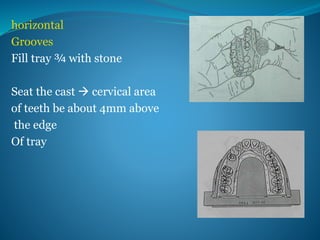

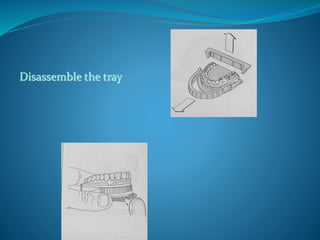

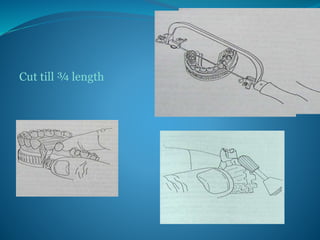

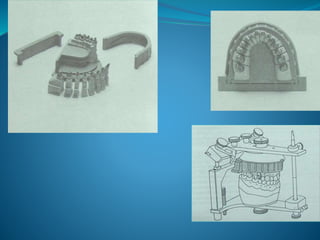

The document discusses various die materials and systems used for indirect restorations. It defines a die as a positive reproduction of a prepared tooth used to fabricate restorations outside the mouth. Common die materials include gypsum, resins, metals and polymers, each with advantages and disadvantages. Removable die systems like dowel pins, Di-Lok and Pindex are discussed which allow repositioning of dies in the working cast for wax pattern fabrication. Proper selection of die material and system depends on factors like accuracy, strength and compatibility with impression materials.