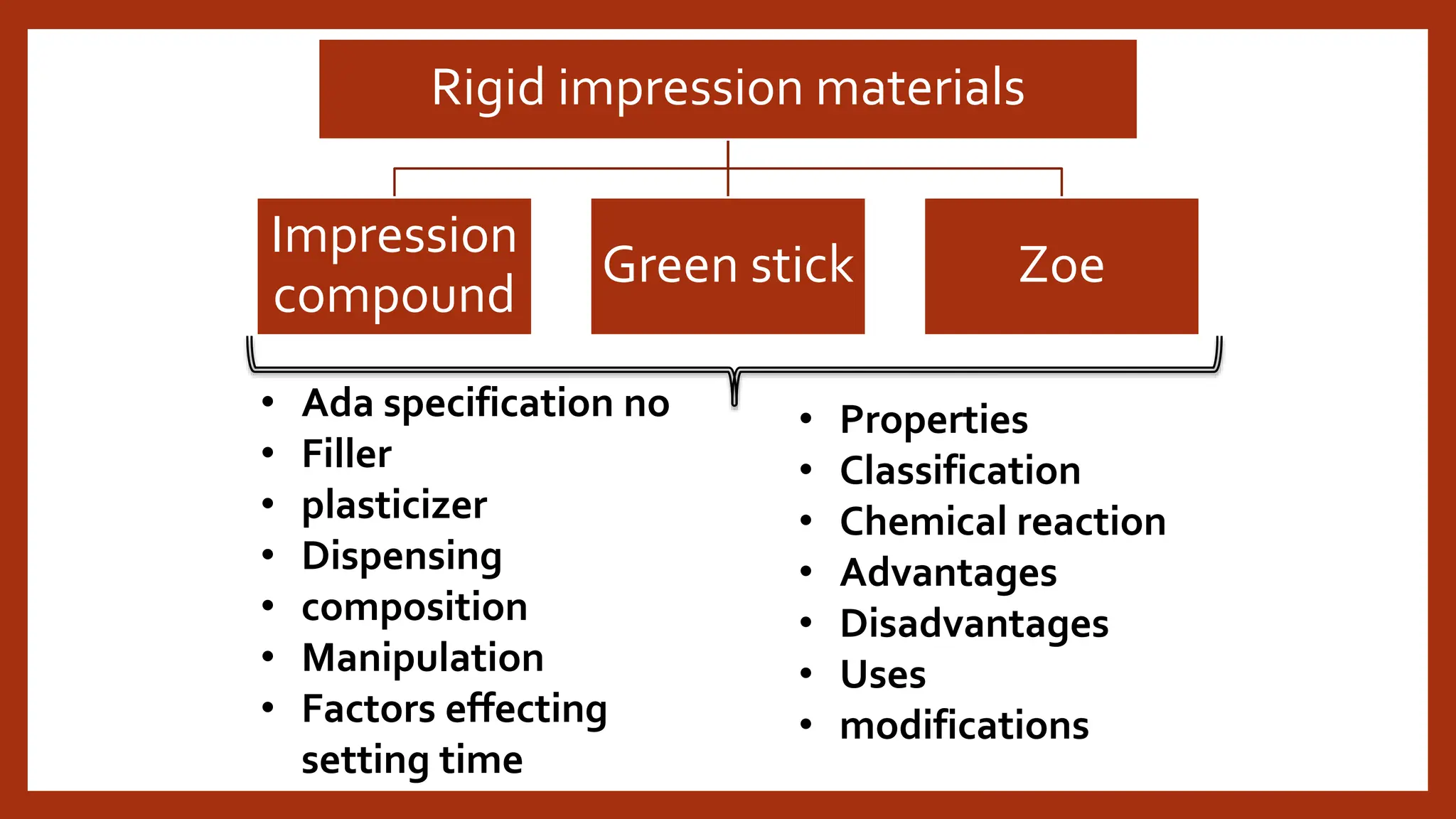

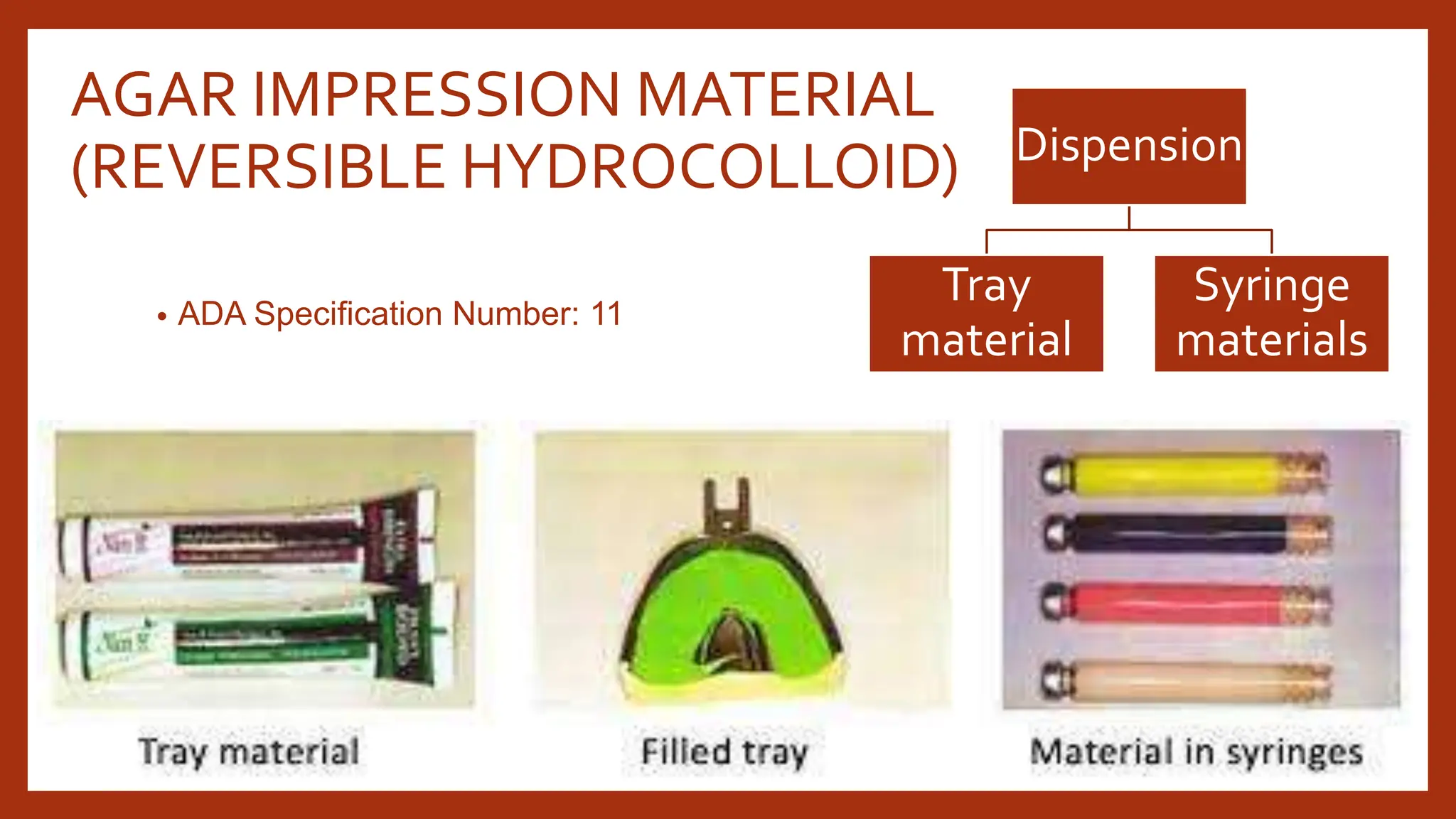

The document discusses various types of impression materials, focusing on rigid and non-rigid options such as impression compounds, alginate, and agar. Key concepts include the classification of materials, their properties, manipulation techniques, advantages and disadvantages, as well as the gelation process. Additionally, it covers applications in dental impressions and specific techniques used in the field.