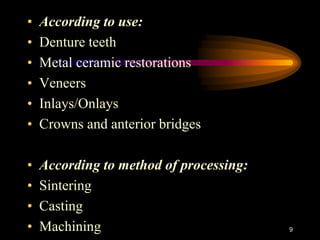

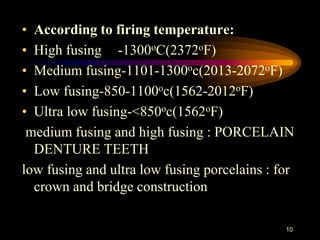

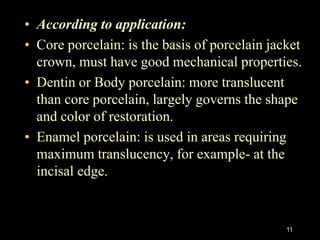

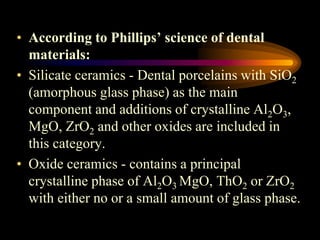

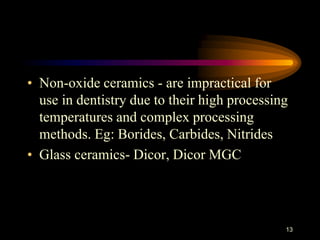

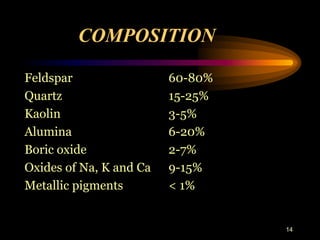

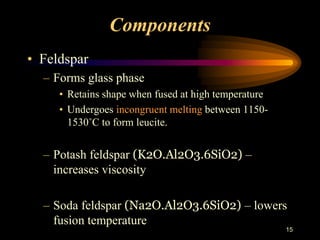

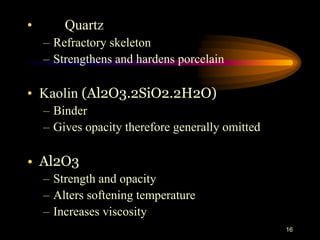

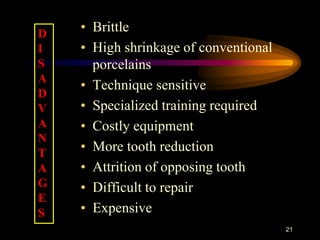

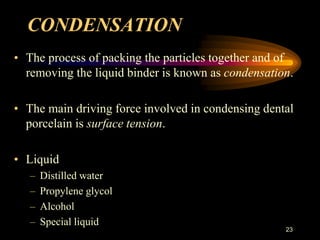

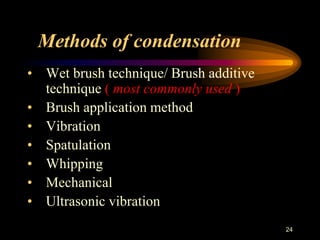

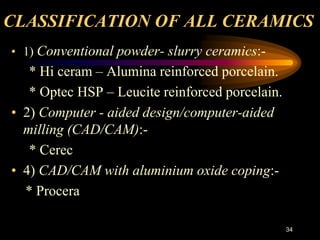

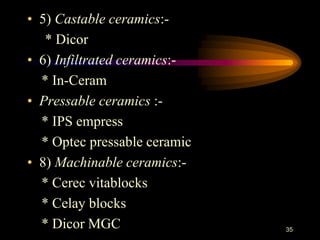

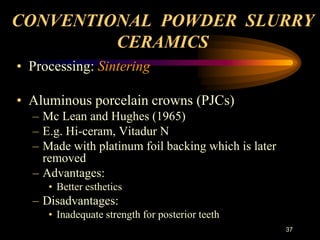

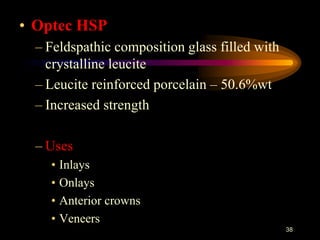

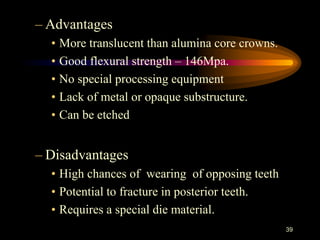

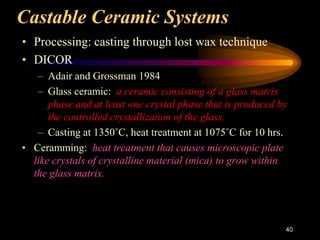

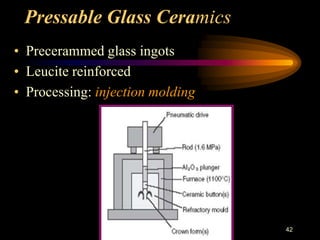

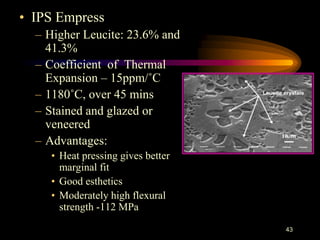

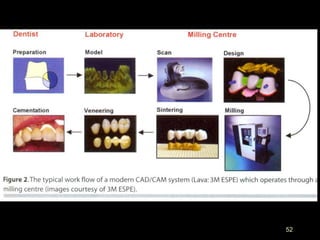

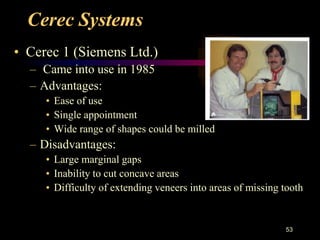

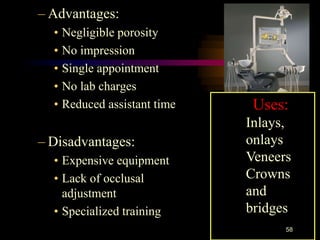

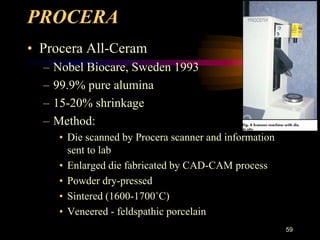

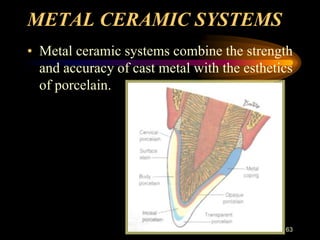

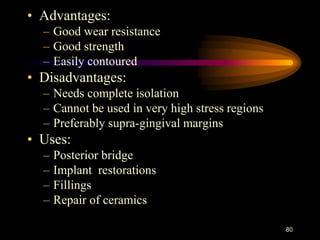

This document provides an overview of dental ceramics. It discusses the historical perspective of dental ceramics dating back 23,000 years. It also covers the classification, composition, properties, processing methods like condensation and firing, and advances in all-ceramic and metal-ceramic dental systems. The document contains detailed information on the composition, properties and processing of various dental ceramic materials like feldspathic porcelain, leucite-reinforced porcelain, and glass ceramics. It compares conventional powder-slurry ceramics with newer CAD/CAM and machinable ceramic materials.