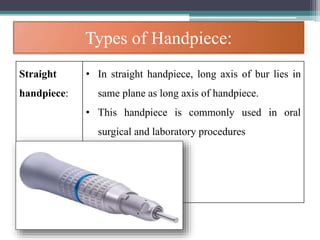

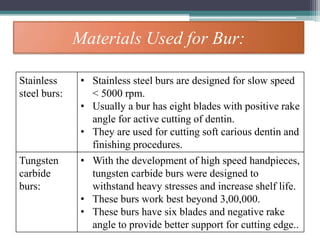

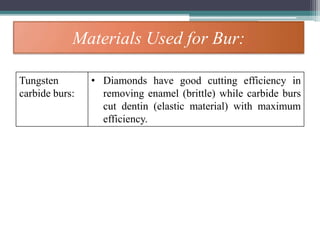

1) Rotary cutting instruments called burs are used to abrade and cut tooth structure when attached to a powered handpiece. Burs come in various shapes, sizes, and materials like stainless steel and tungsten carbide.

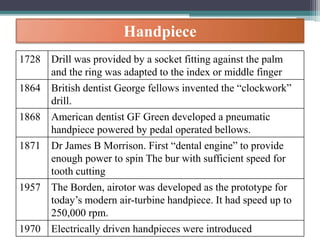

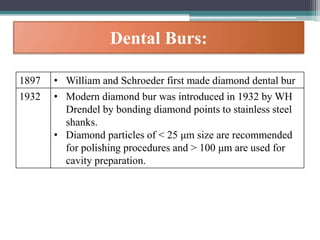

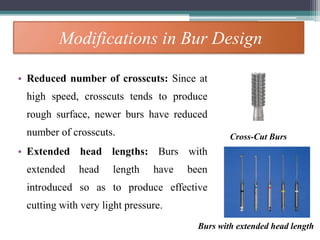

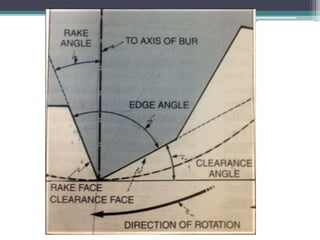

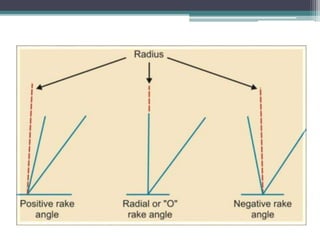

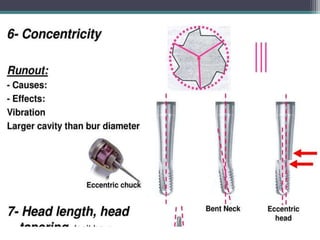

2) Bur design features like rake angle, clearance angle, and number of blades influence cutting efficiency. Developments in handpieces and burs have improved power and lifespan.

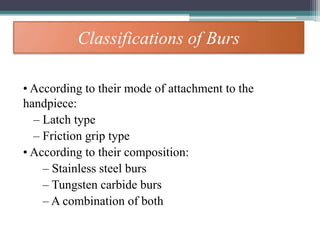

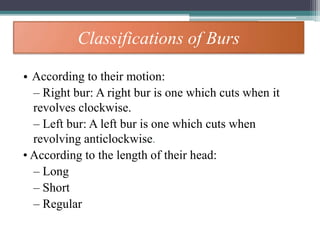

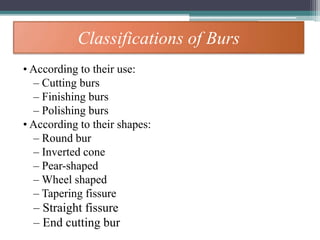

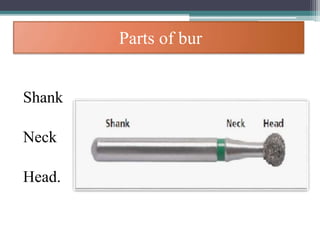

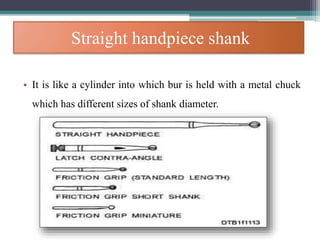

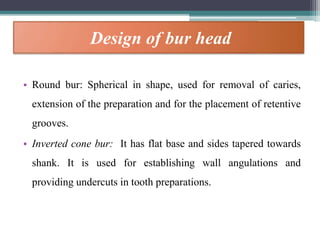

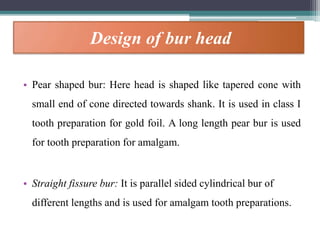

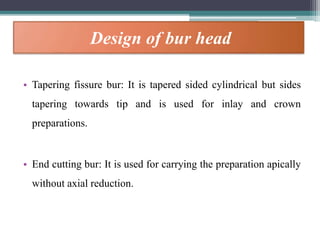

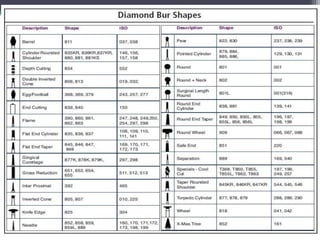

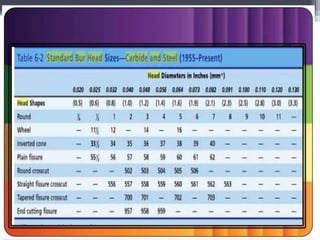

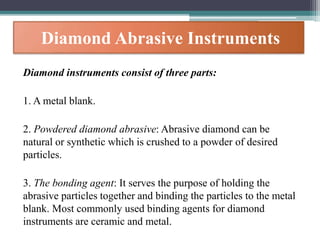

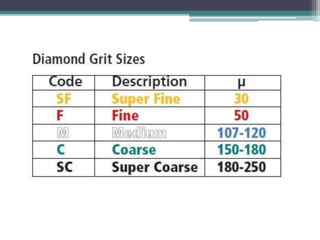

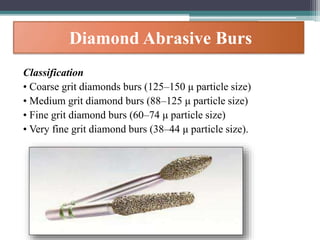

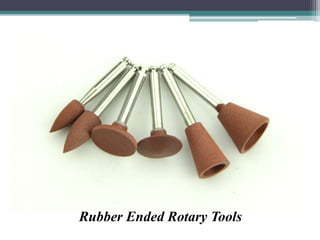

3) Burs are classified by attachment type, material, shape, length, and intended use. Finishing burs smooth surfaces while abrasives like diamonds shape tooth structure without cutting.