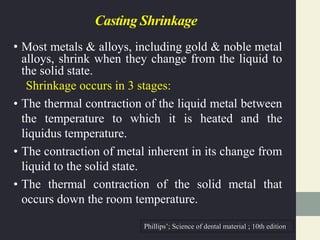

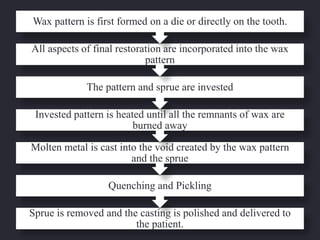

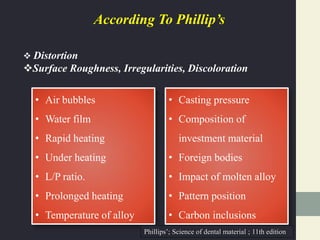

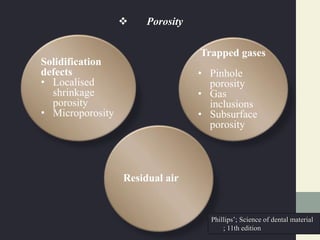

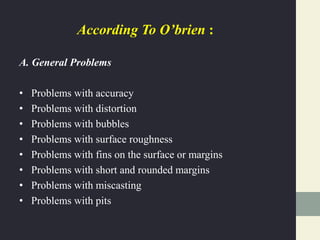

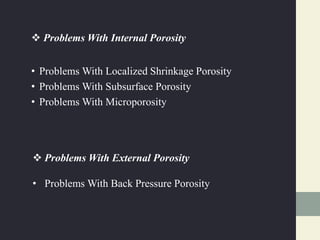

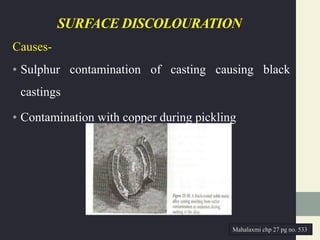

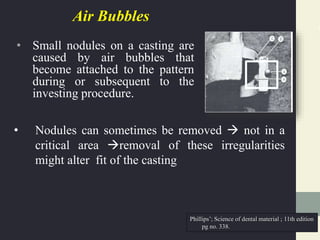

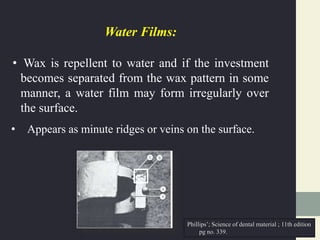

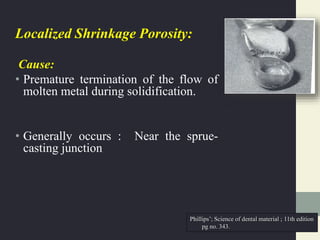

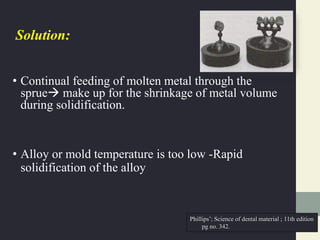

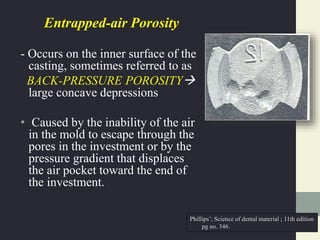

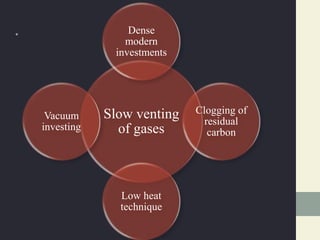

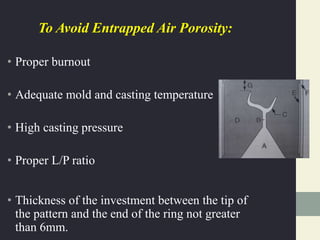

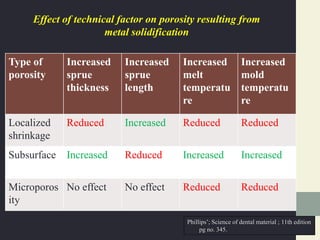

El documento detalla los defectos que pueden ocurrir durante el proceso de fundición dental, describiendo diversas causas como contracción, burbujas de aire y problemas de precisión. Se clasifican los defectos en categorías como distorsión, porosidad y descoloración, y se ofrecen soluciones para evitar estos problemas. Asimismo, se discuten los materiales de inversión utilizados y los diversos tipos de porosidad que pueden afectar la calidad del producto final.