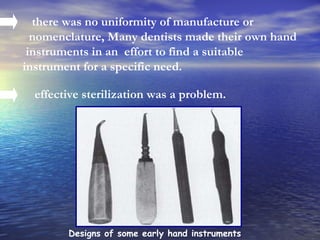

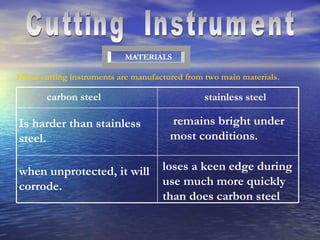

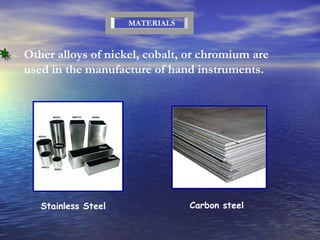

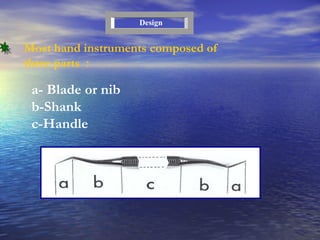

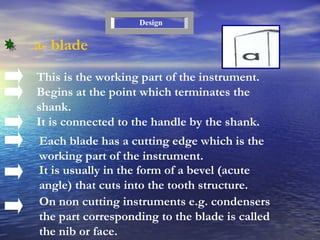

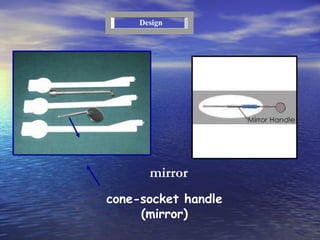

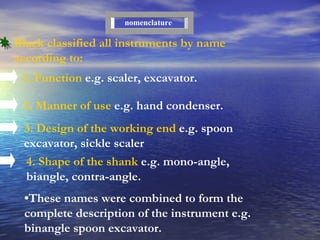

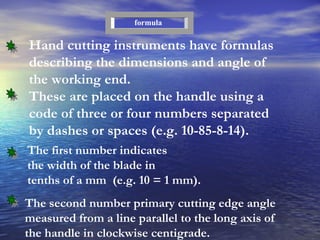

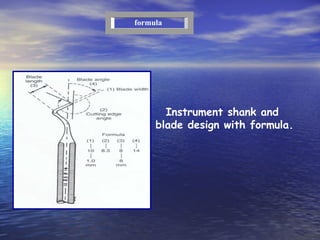

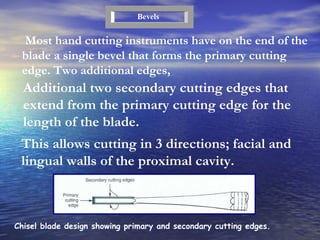

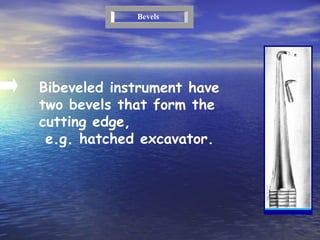

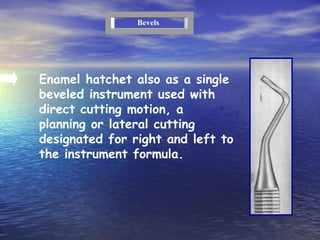

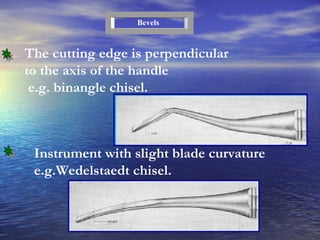

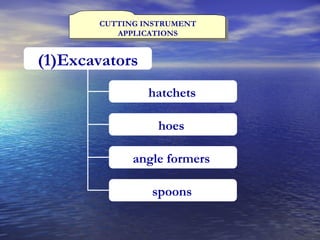

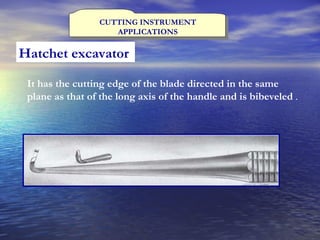

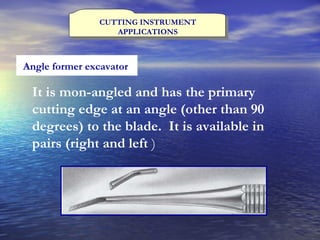

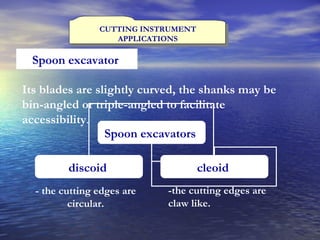

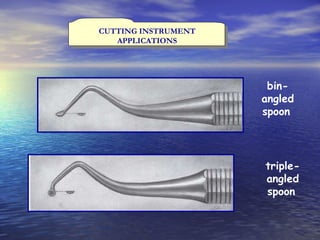

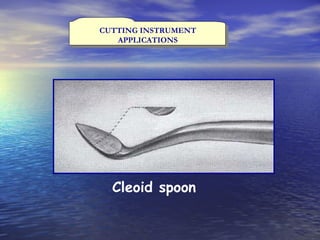

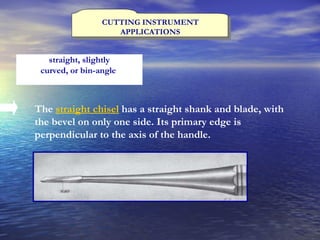

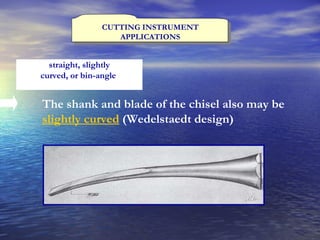

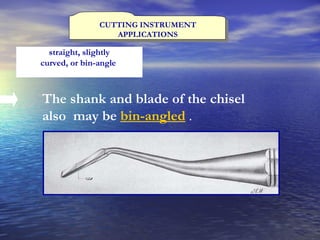

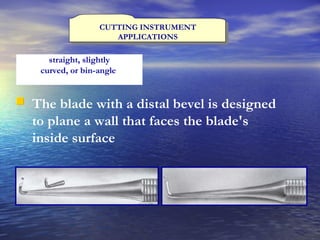

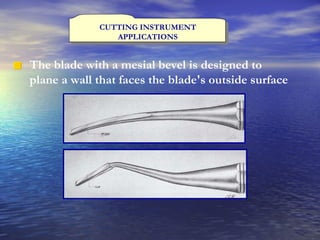

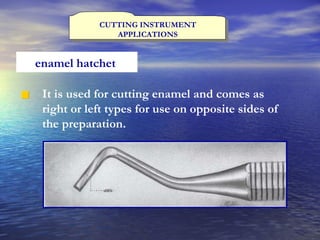

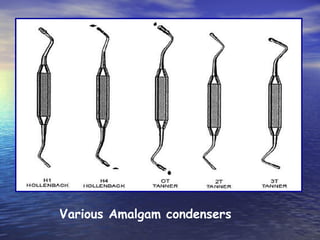

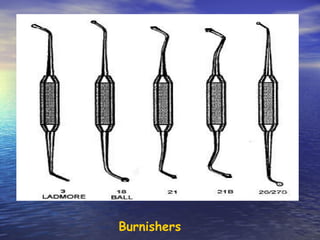

This document summarizes hand instruments used in dentistry. It describes how instruments are classified as either cutting or non-cutting. For cutting instruments, it discusses common materials used like carbon steel, design features such as bevels, and applications like excavators and chisels. Excavators are used to remove caries and refine cavity preparations, and come in styles like hatchets, hoes, and spoons. Chisels are also used to cut enamel and come in straight, curved, or angled styles. Non-cutting instruments include mirrors, probes, and amalgam condensers.