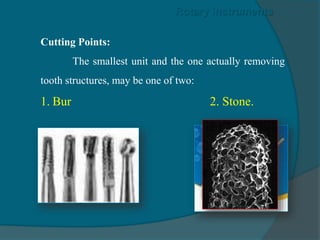

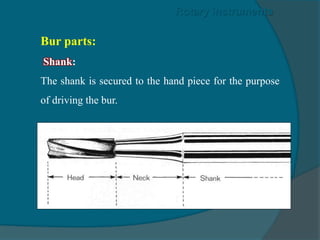

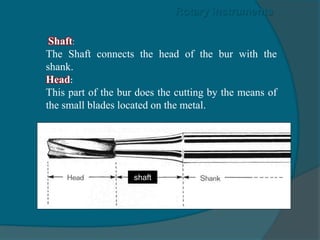

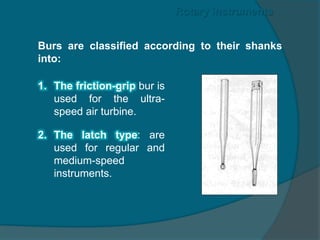

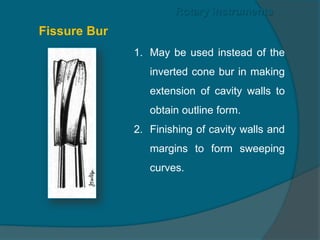

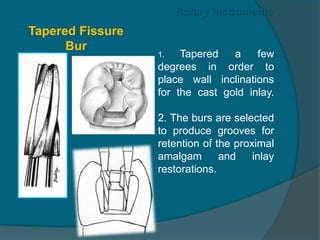

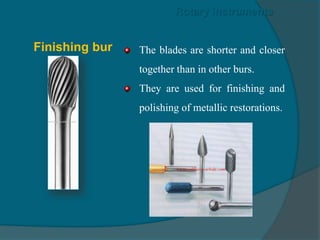

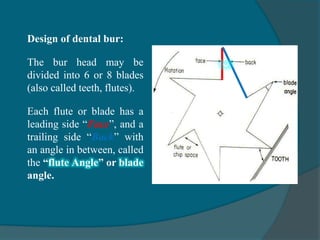

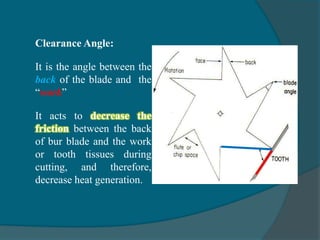

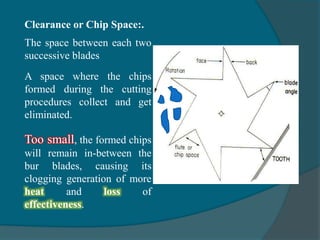

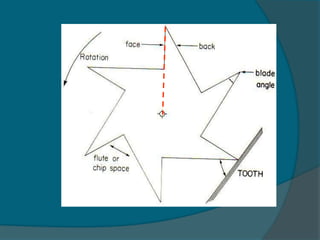

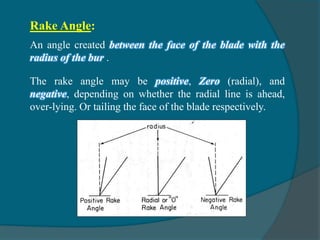

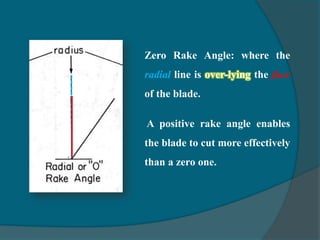

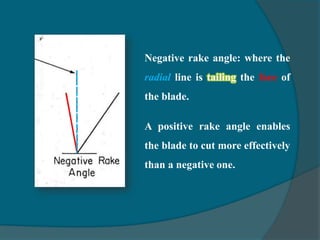

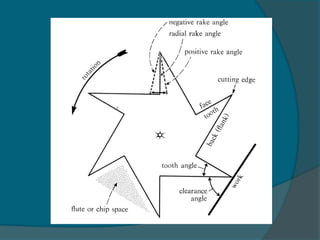

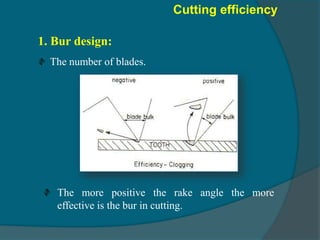

The document discusses rotary instruments used in dentistry, categorizing them by operating speed and detailing their components, such as the bur, shank, and head. It explains different types of burs and their specific functions in procedures like cavity excavation and finishing. The text also addresses design factors affecting cutting efficiency, including clearance angle and rake angle, which influence how effectively the instrument removes tooth structure.