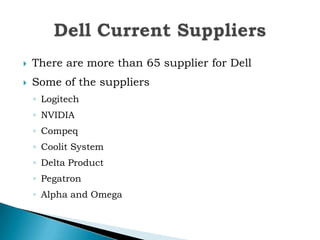

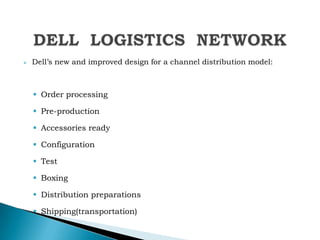

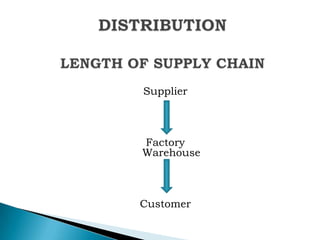

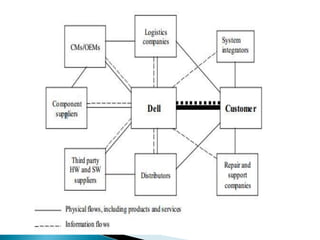

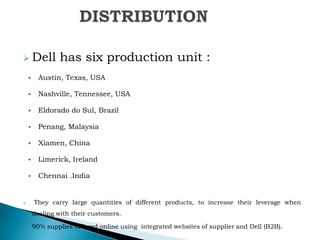

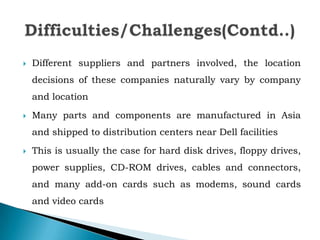

Dell was founded in 1984 by Michael Dell and is known for innovations in supply chain management. It sells computer systems directly to customers, eliminating retailers and allowing Dell to build each system to order. Dell has over 65 suppliers globally and chooses large suppliers that can keep up with demands. It uses a build-to-order model with factories having only 7 hours of inventory and materials sent directly to assembly lines. Dell localizes production and parts sourcing near its assembly plants to optimize supply chains.