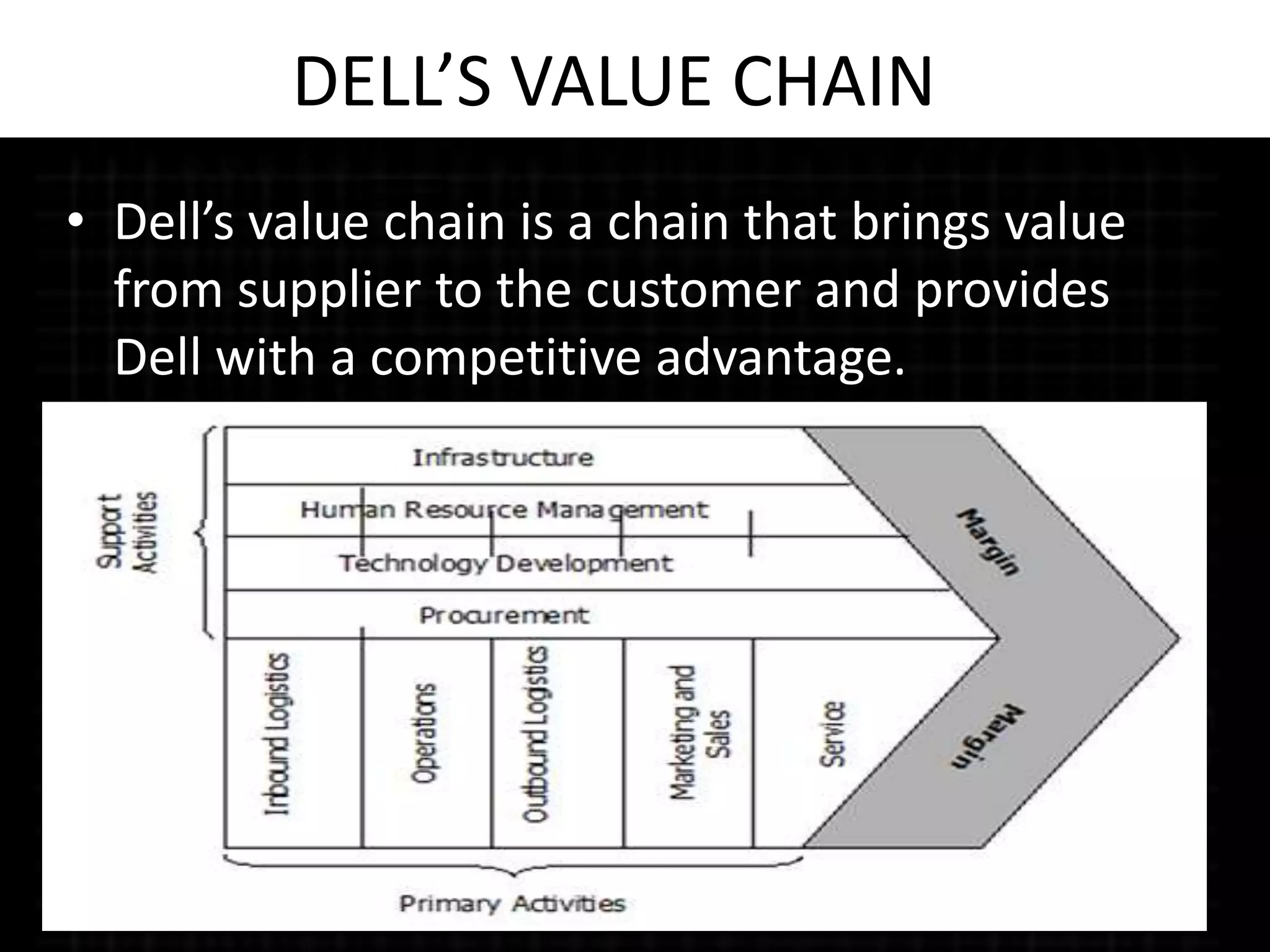

Dell Inc. is a leading American multinational computer technology company based in Texas, known for its direct-sales model and customizable PC manufacturing. The company's supply chain strategy emphasizes responsiveness and supply chain integration to meet customer demands efficiently while minimizing costs. Dell utilizes a combination of direct and retail distribution channels to enhance its market reach and maintain competitiveness.