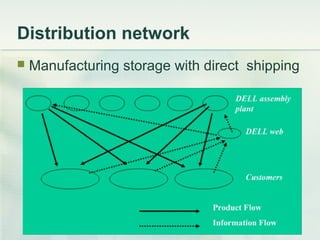

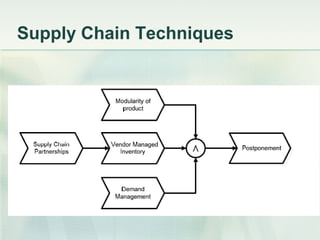

Dell revolutionized the computer industry by pioneering a direct sales model that eliminated intermediaries. Dell's supply chain is built around building computers to customer order, which allows Dell to minimize costs by reducing inventory and producing only what customers demand. Dell achieves this through a combination of direct sales, build-to-order manufacturing, and close integration with suppliers.