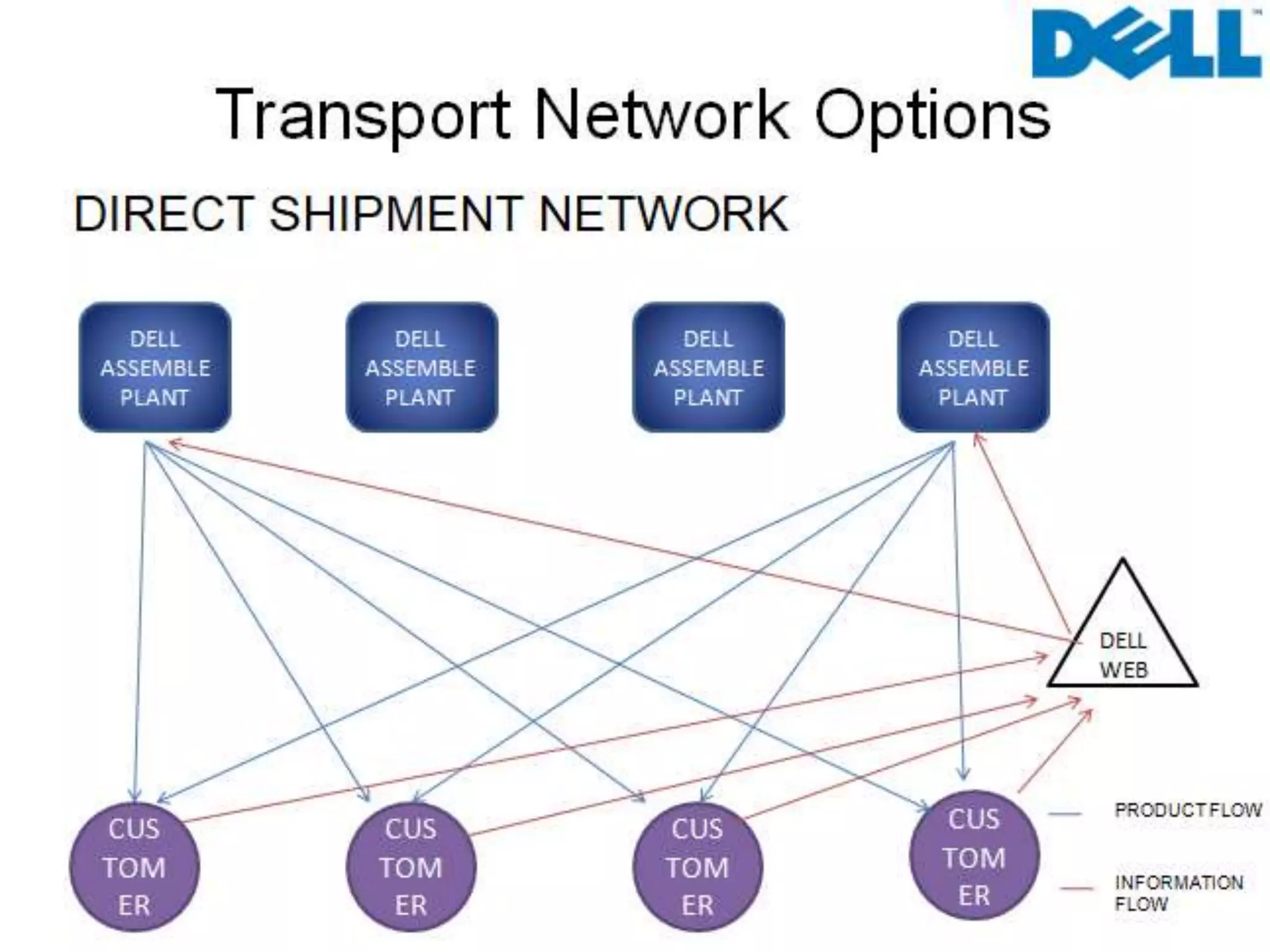

Michael Dell founded Dell in 1984. Dell is known for innovations in supply chain management and sells computer systems directly to customers, eliminating retailers. Dell uses a build-to-order model where customer orders trigger production. Dell chose i2 Technologies' SCM system to aggregate orders every 20 seconds, analyze material needs, and create supplier bills. Dell aims for just-in-time inventory, receiving exact materials every two hours. Factories have only seven hours of inventory. Distribution occurs through Dell's six production units globally. Benefits include lower costs, cash flow from payment receipt before paying suppliers, and customized systems through direct customer relationships.