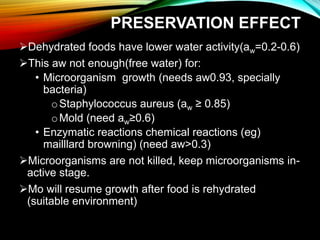

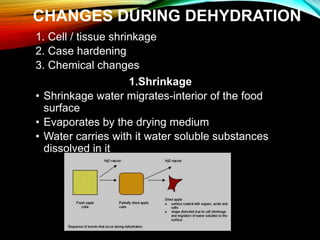

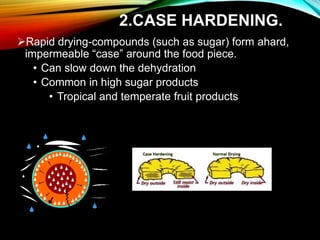

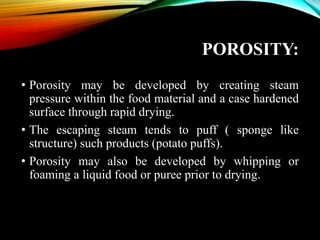

Dehydration is the process of removing water from food to extend its shelf life by inhibiting microbial growth and enzyme activity. The document discusses various methods of dehydration, factors affecting it, and the changes that occur in food during the process, including loss of texture, flavor, and color. It also highlights the advantages and disadvantages of dehydrating foods, particularly in relation to nutritional value and microbial growth control.