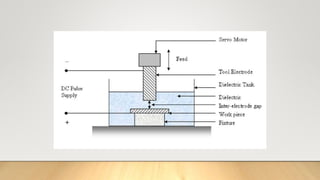

Electric discharge machining (EDM) is a process that uses controlled sparks to erode electrically conductive materials, facilitated by a dielectric fluid medium. The method is effective for shaping hard materials and crafting complicated designs, but it has limitations including slow processing speed and high power consumption. Common applications include reshaping cutting tools and creating small holes in hardened parts.