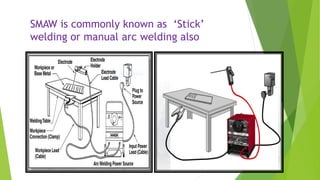

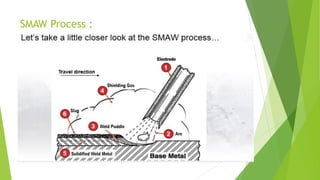

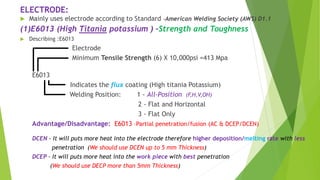

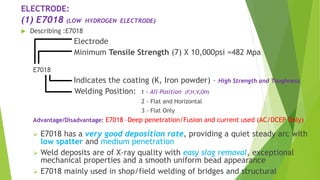

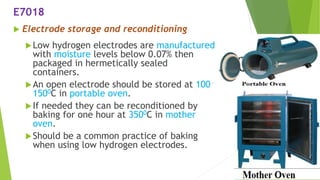

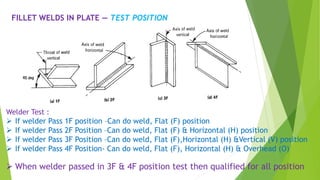

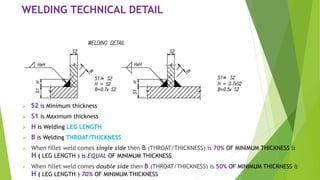

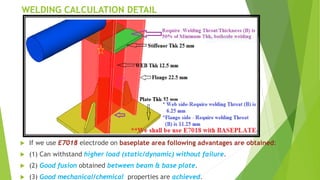

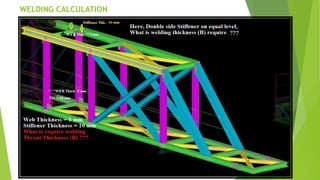

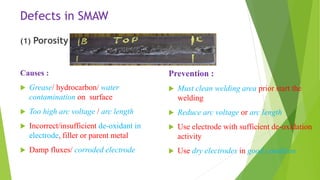

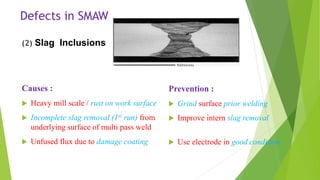

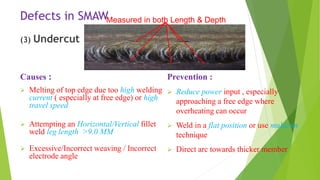

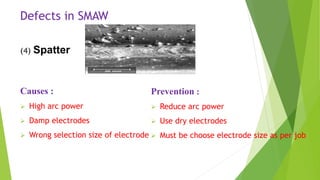

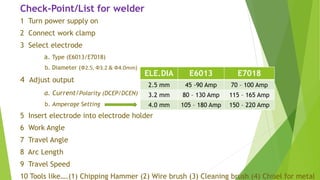

This document provides a training presentation on shielded metal arc welding (SMAW), also known as stick welding. It discusses electrode types E6013 and E7018, including their composition, properties and applications. It also covers topics like welding positions, defects, calculations, storage and techniques. The presentation aims to equip welders with knowledge on performing SMAW and passing certification tests for different welding positions.