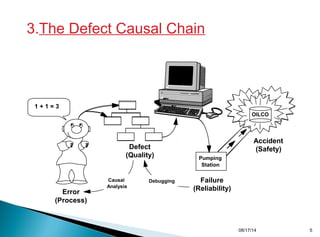

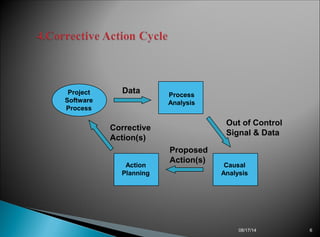

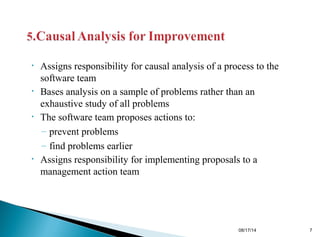

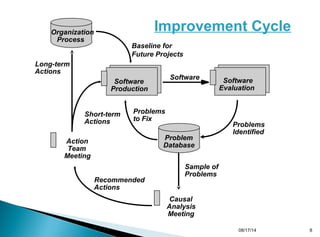

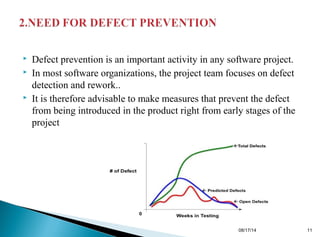

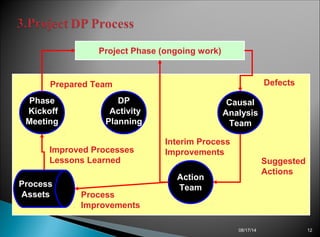

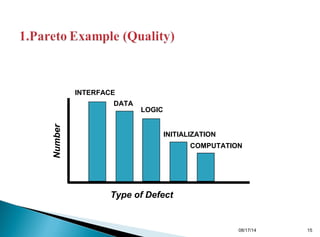

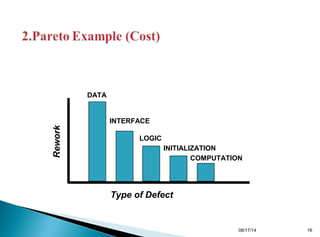

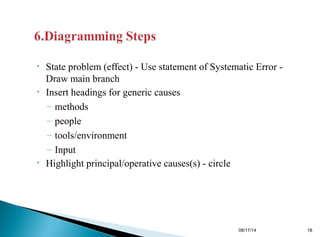

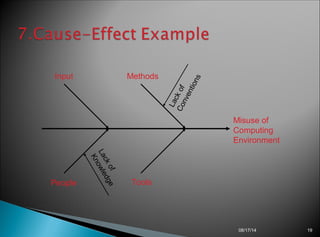

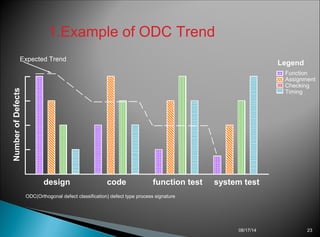

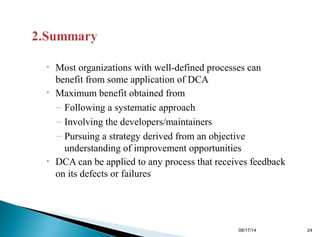

The document discusses defect analysis and prevention. It defines key terms like errors, defects, and failures. It describes the defect analysis procedure which includes forming a causal analysis team to identify root causes of defects so they can be prevented. The team proposes actions, while an action team implements solutions. Data on defect types and trends is analyzed to prioritize issues. Tools like fishbone diagrams may be used to sort contributing factors. The goal is to systematically eliminate common causes of defects.