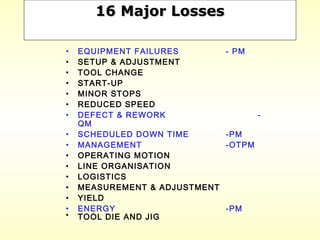

16 major losses tng

- 1. • EQUIPMENT FAILURES - PM • SETUP & ADJUSTMENT • TOOL CHANGE • START-UP • MINOR STOPS • REDUCED SPEED • DEFECT & REWORK - QM • SCHEDULED DOWN TIME -PM • MANAGEMENT -OTPM • OPERATING MOTION • LINE ORGANISATION • LOGISTICS • MEASUREMENT & ADJUSTMENT • YIELD • ENERGY -PM • TOOL DIE AND JIG 16 Major Losses16 Major Losses

- 2. Loss Structure During Production Activities (16 MajorLosses) Operating Man-hours Net Operational Man-hours Effective Man- hours Valued Man- hours (Man- hours for turnout) Loading Man-hours Working Hour Operating Time Net Operating Time Valued Operating Time Loading Time 9. Management loss 10. Operating motions loss 11. Line organization loss 12. Logistics loss 13. Measurement and adjustment loss 5MajorLossesObstructingManpowerEfficiency Excluding man-hours (Supported by other departments) Production Man-hour Line organization man-hour loss Defects in man- hour loss Defects quality loss 8. Shutdown loss 1. Equipment Failure loss 2. Set-up and adjustment loss 3. Cutting blade and Jig change loss 4. Start-up loss 5. Minor stoppage idling loss 6. Speed loss 7. Defects and rework loss Other downtime loss Clearing checking Awaiting instruction Awaiting materials Awaiting personnel distribution Quality confirmation (Adjustment of measurement) 8Majorlossesobstructingequipmentefficiency Scheduled downtime Downtime Performance loss Start-up loss Overload loss Temperature loss 14. Energy loss Input energy Effective energy No. of qualified products Input materials (Number, weight) Weight of qualified products Defects quality loss Start-up loss Cutting loss Losses in weight Losses in overages (Increased commission) 16. Yield loss 15. Die, tool & jig loss Efficiency of material, die, jig, tool and energy requirement per product unit .... 3 Major losses obstructing efficiency of material, Die, Jig & energy requirement per product unit

- 3. (1) Failure losses The definition of failure loss is set as follows: Cases accompanied by function stoppage or decline (normally or typically accompanied by production stoppage or output decline) Cases requiring replacement of parts or repair in order to recover function Cases requiring 5-10 minutes or more for repair • At any rate, failures must be reduced to zero. This can be attained at little cost, although some short-term investment may be necessary. To attain zero failures, it is necessary to correct the conventional misconception about BM (breakdown maintenance) that failures are unavoidable

- 4. GENERAL PROBLEMS WITH FAILURES Low interest by production sector • Production thinks failures should be handled by maintenance. Weak attitude toward failure analysis. • Phenomena are not observed in details. • Broken locations and places nearby are not examined fully. • Enough ‘Genbutsu’ is not collected and analyzed. • Causes are not pursued fully and only actions are taken. • Measures for preventing recurrence are not taken. • Failures are not analyzed at on-site. Maintenance system and operation of it are weak. • Check criteria are not defined, eg., checking frequency, locations, method and criteria. • Maintenance calendar easily showing parts replacement and overhauling periods, oiling and oil change, and other items and operation system for it are week. • Failure history system. Attitude toward predictive maintenance (CBM) is weak. • Measured values fluctuate greatly and re not reliable. • Measured values do not change for a long time and lose confidence in audit results. • Periodic measurement and trend control are not implemented.

- 5. Relations of Causes and Effects of Failures Results Causes To err is human

- 6. (2) Setup and adjustment losses "Setup and adjustment losses" refers to time losses from the end of the production of a previous item through product-change adjustment to the point where the production of the new item is completely satisfactory. Setting up means a series of operations from the removal of jigs and fixtures following the end of production, clearing up and cleaning, through the preparation of jigs/tools and metal fixtures necessary for the next product, to their attachment, adjustment, trial processing, readjustment, measurement, production, and finally the ability to produce excellent products Contd…..

- 7. Adjustment means the following: Taking measures to implement optimum solutions/values for specific purposes, for instance, steps to restrict quality within a target value range or to prevent other problems. Attaining certain aims through repeated trial and error. The approach to be adopted should be to study the adjustment mechanism and seek time reduction. The ultimate goal of the approach is "minimisation.' The final objective of set-up & adjustment losses is to realise “one-shot machining in which quality production is possible ”. To realize one-shot arrangements, it is essential to reduce adjustment to zero.

- 9. Why can’t we achieve One-step defect free change over ? •We assume that adjustments are simply inevitable in a high precision process •Our equipment and replaceable parts have poor precision so we make adjustments to compensate •The standards mounting points are not clearly defined with numerical values so people have to guess at the setting. •We don't know the proper machining conditions or if we do we aren’t applying that knowledge during set-up. (No standards procedures)

- 10. Steps of promoting single step defect free change over Understand the current process & condition Clarify the problem areas in changeover adjustment & test runs Check the precision of the equipment and replaceable parts Improve your positioning methods Take care of remaining adjustments Carry out PM analysis ( systematic thinking using the principles & stds of the process) Look again at stds values & check the items related to eqpt precision Look again at the machining condition. Look again at durability. Look again at the quality of pervious machining Create changeover Stds: Maintain & management

- 12. (3) Cutting-blade losses These are time losses due to regular cutting-blade exchanges and extraordinary replacement necessitated by blade damage and volume losses (defects and rework) that arise before and after blade replacement. Cutting-blade losses are dropping due to material and shape studies yielding longer blade life, but they still pose a problem requiring further study. In the case of transfer machines, cutting- blade losses may account for 10% to 12% of overall efficiency impedance, because the number of operators is few in relation to the number of the machines. The reduction of cutting-blade losses requires study in both the fields of relevant technology (material changes, shape alteration, etc.) and software (vibration measurement and pursuit of optimum cutting conditions). The target is the maximisation of blade life

- 13. (4) Start-up losses Start-up losses are defined as time losses from •start-up after periodic repair, •start-up after suspension (long-time stoppage), •start-up after holidays, •start-up after lunch breaks, to the time when it is possible to produce excellent products of reliable quality, free from machine problems (minor stoppages, small problems, and blade breakdown) in a specified cycle time operation, as.well as volume losses (defects/ rework) that arise during that period.

- 14. • Method of reducing start-up losses – Time-series data at the time of start-up – Examination of working oil/lubricating oil – Examination of related equipment portions – Adjustment of thermal displacement occurrence portions – Measurement of thermal displacement values – Countermeasures

- 15. 5) Minor stoppage & idling losses The definition of these losses is as follows: • Losses that are accompanied by temporary functional stoppage • Losses allowing functional recovery through simple measures (removal of abnormal work pieces and resetting) • Losses that do not require parts exchange or repair • Losses that require from 3-5 seconds to less than 5 minutes for recovery. Unlike failures, minor stoppage/idling losses represent the condition in which equipment stops or idles because of temporary problems; for example, a work piece clogs a chute, or a sensor is triggered by a quality defect, temporarily stopping the machine. In this case, if the work piece is removed and resetting is done, the machine will operate normally. Thus, this condition is different in character from equipment failure

- 16. GENERAL PROBLEMS ON MINOR STOPPAGES • Efforts to actualize as losses are not sufficient. • Actions taken are poor - Only emergency measures are taken as temporary measures. • Phenomena are not discerned fully. • Obstruction to un-attended operation. - Operators are used for restoration. - Minor stoppages keep operators from operating multiple stations or machines. - One minor stoppage will ruin the effects of unattendance operation during breaks

- 18. 7) Defect / Rework losses Defect/rework losses are defined as volume losses due to defects and rework (disposal defects), and time losses required to repair defective products to turn them into excellent products. Generally, sporadic defects are easily fixed, so they are rarely left uncorrected. Chronic defects, in contrast, are often left as they are, because their causes are difficult to perceive and measures to correct them are seldom effective. Rework and repair items are also regarded as chronic defects, because modification worker-hours are required

- 20. Basic principle of quality maintenance Quality Defects Defects due to equipment precision Defects due to Machining conditions Defects due to People involved Creation of equipment that doesn’t produce defects Train operators who know their equipment well Setting std: conditions for equipment that doesn’t produce defects Fostering maintenance management ability Management of std: condition that doesn’t produce defects Zero defects

- 22. Overall Equipment Effectiveness - OEE • A Formula for measuring Equipment Utilization and Performance • Uses an “Industry Standard” list of Downtime Reasons • The data required for accurate OEE calculations can provide MTBF’s, MTBE’s, and MTTR’s information for equipment.

- 23. Overall Equipment Effectiveness OEE = Availability x Performance x Quality where: Availability = Equipment Availability Performance = Performance Efficiency Quality = Quality Rate (The OEE Equation)

- 24. Loading time - Downtime Loading Time = x 100Availability Performance efficiency Processed amount Operating Time/ Theoretical cycle time(@ 100% eff & without Occ Time ) x 100= Rate of quality products Processed amount - defect amount Processed amount = x 100 FOR OEE

- 25. Relationship between Six MajorLosses on Equipment and Overall Equipment Effectiveness Availability Loading time - Downtime Loading Time = x 100 = x 100 = 87% 460 mins. - 60 mins. 460 mins. (e.g.) : Availability Performance efficiency Theoretical cycle time x processed amount Operating Time = x100 = x 100 = 50% 0.5 mins./unit x 400 units 400 mins. (e.g.) : Performance efficiency Rate of quality products Processed amount - defect amount Processed amount = x 100 = = x 100 = 98 % 400 units - 8 units 400 units (e.g.) : Rate of quality products Overall equipment effectiveness = Availability x Performance efficiency x Rate of quality products (e.g.) 0.87 x 0.57 x 0.98 x 100 = 42.6% Equipment failure 1 Operating time Downtime losses Net operating time Speedlosses Valuable operating time Defectlosses Loading time Setup and adjustment 2 Idling and minor stoppage 3 Reduced speed 4 Defects in process 5 Reduced yield 6 Equipment Six Major Losses Calculation of overall equipment effectiveness

- 26. Relationship between Six MajorLosses on Equipment and Overall Equipment Effectiveness Availability Loading time - Downtime Loading Time = x 100 = x 100 = 87% 460 mins. X 60 mins. 460 mins. (e.g.) : Availability Performance efficiency Theoretical cycle time x processed amount Operating Time = x100 = x 100 = 50% 0.5 mins./unit x 400 units 400 mins. (e.g.) : Performance efficiency Rate of quality products Processed amount - defect amount Processed amount = x 100 = = x 100 = 98 % 400 units - 8 units 400 units (e.g.) : Rate of quality products Overall equipment effectiveness = Availability x Performance efficiency x Rate of quality products (e.g.) 0.87 x 0.57 x 0.98 x 100 = 42.6% Equipment failure 1 Operating time Downtime losses Net operating time Speedlosses Valuable operating time Detectlosses Loading time Setup and adjustment 2 Idling and minor stoppage 3 Reduced speed 4 Defects in process 5 Reduced yield 6 Equipment Six Major Losses Calculation of overall equipment effectiveness 9. Management loss

- 27. Overall Equipment Effectiveness = A x P x Q Processed amount - defect amount Loading Time/ Theoretical cycle time(@ 100% eff & without Occ Time )

- 28. For Calculating the OEE for the line, the line is considered as one entity (machine) 1 3 2 4 5 7 6 8 IN OUT Std output of the line is taken

- 29. Overall Planned effectiveness Availability Loading time - Downtime Loading Time = x 100 = x 100 (e.g.) : Availability Performance efficiency Actual average Production Standard production = x 100 = x 100 (e.g.) : Performance efficiency Rate of quality products Production - 7 8 Production = x 100 = = x 100 (e.g.) : Rate of quality products Overall planned effectiveness = Availability x Performance efficiency x Rate of quality products Planned Maintenance & Equipment failure 1 Running B Hours Lossby Suspension Operation C Hours Lossby stoppage Net Operation Hours D LossByCapacityCalander Hours A Production control 2 Equipment breakdown3 Process breakdown4 Regular Production5 Irregular production6 Equipment Six Major Losses Calculation of overall equipment effectiveness Valuable operating timeE LossBy Deficiency Process deficiency 7 Reprocessing 8 C A C D D E

- 30. Loading time - Downtime Loading Time = x 100Availability Performance efficiency Processed amount Operating Time/ Theoretical cycle time(@ 100% eff & without Occ Time ) x 100= Rate of quality products Processed amount - defect amount Processed amount = x 100 FOR OPE ( Down time include Scheduled down time also )

- 31. PRODUCTIVITY MEASUREMENT SYSTEM Performance Efficiency OEE Quality Rate Setup AdjustBreakdowns Tooling Availability Startup Losses •Maintenance repair histories •Operator log sheets •Equipment failure reports •Process Controllers Examples: •Wear Part failure •Utility failure •Equipment jam •Lubrication failure •Process Controllers •Production schedules •Setup log sheets •Tool changeover report •Production control system Examples: •Part Changeover •Die Change •Tooling Change •Limit Switch adjust •Set point Adjustment •Running of test Parts •Process Controllers •Production log sheets •FMEA Examples: •Cutting tool wearout •Injection Mold failure •Stamping Die failure •Operator log sheet •Process Controllers •Production count •Start meters Examples: •Injection Molding machine partial full on initial run. Idling & Minor Stoppages Speed Losses •Process Controllers •Operator log sheet Examples: •Running at less than design speed to meet quality specifications •Not knowing the capability of a machine or line. •Operator check off document •Process Controllers Examples: •Machine Jam •Manual adjustment •Material misalignment •Machine reset •Production Reports •Quality Control Charts •Reject rates Quality Defects Major Losses

- 32. Set model equipment Organise the project team Improvementof equipmentefficiency Track Seven major Losses Select the theme & plan implementation Individual improvements project activities Individual improvements project activities Reliability in use- prevention stds & review Autonomous maintenance system Preventive maintenance system Horizontal deployment Bottle neck process Large loss More H.D applicable Matching with JH machine Eqpt Failure loss Minor stoppage loss Set up and adjustment loss Cutting tool & jig change loss Start up loss Reduced speed loss Defect & rework loss } } Function failure loss( Failure analysis technique) Function depression loss (IE, QC, VE) Challenge ‘0’ seven major losses through project activities under each theme Individual improvement

- 33. Sporadic & chronic losses Division Sporadic loss Chronic loss Loss Mode Entirely new phenomenon suddenly occurs. Phenomenon occurs suddenly after exceeding a certain dispersion range Phenomenon occurs within a certain dispersion range -Repeated in short cycles -Phenomenon always occurs with certain quantitative dispersions Actualization Recognized as loss compared with present level. Actualize as loss compared between maximum value and technical level Cause Casual sequence is relatively monotonous. Can be guessed by past experience and intuition in many cases Casual sequence is not clear and cause system is compounding. Past experience and intuition do not work. Countermeasure Most cases can be solved on the spot. Restorative measures will work. Cannot be solved even if various actions are taken. Renovating countermeasure are needed.

- 34. Chronic problems Two types of chronic problem. 1) Problems produced by a single cause but the causes varies from one occurrence to the next. 2) The problem is produced by a combination of causes,which also varies from one occurrence to next Cause Cause Cause Cause Cause Cause Cause Cause Difficulty in pin pointing the cause

- 35. Approach to Chronic Loss Reduction. 1. Analysis Phenomena 2. Review Potential cause-and-effect relationships. } Conduct P-M analysis as part of this approach 3. Expose slight defects hidden within causal factors In exposing slight defects: • Define optimal conditions •Treat even the slightest flaws as significant •Restore optimal conditions

Editor's Notes

- Sporadic losses are bound to attract attention, and therefore countermeasures are readily adopted. Frequent chronic losses, however, may remain un-amended because various countermeasures are ineffective. Since these losses account for the largest weight, each plant takes countermeasures on a priority basis, but the current status seems to be that correction cannot be achieved as desired. To address failure losses, it is necessary to study measures to raise the reliability of equipment and its maintainability to reduce downtime.