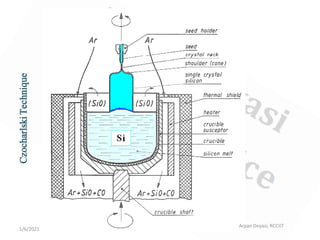

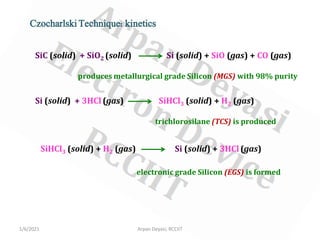

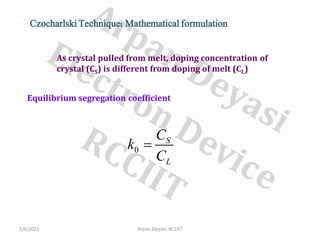

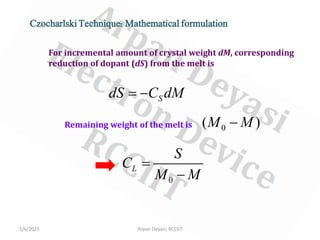

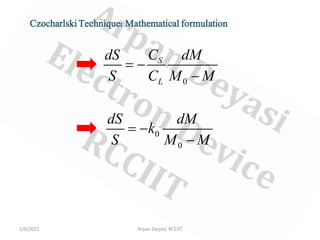

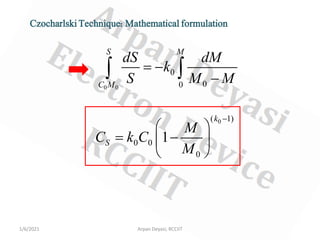

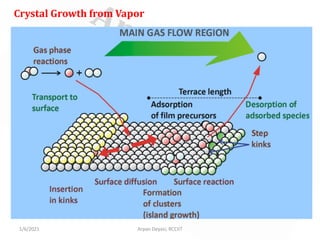

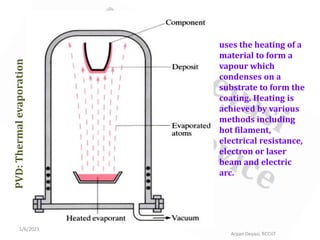

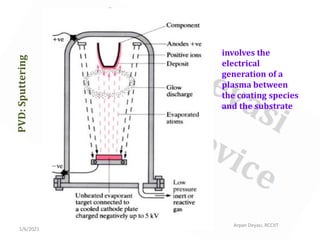

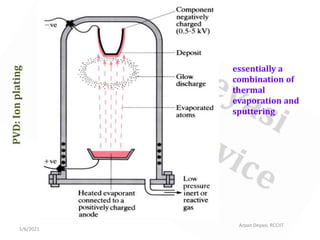

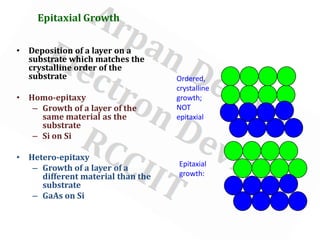

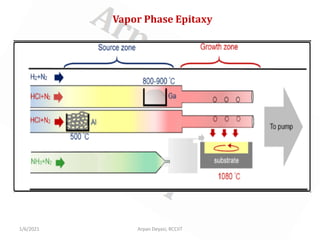

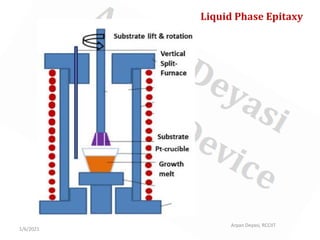

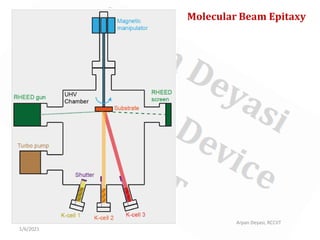

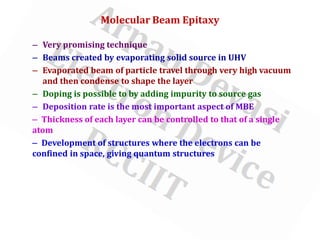

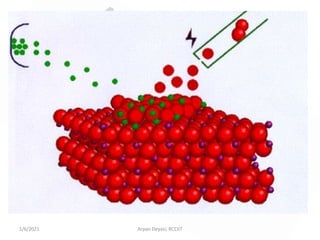

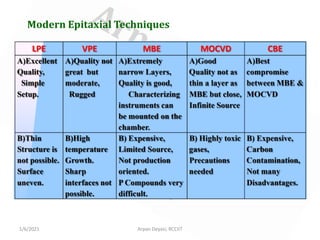

This document discusses various techniques for crystal growth, including growth from melt, vapor, solution, and solid. It focuses on the Czochralski technique for silicon crystal growth from melt. This technique uses a seed crystal pulled slowly from a silicon melt to form a single crystal ingot. The document provides mathematical formulations to describe the technique and discusses advantages like growth of large oriented crystals and disadvantages like potential melt contamination. It also covers physical vapor deposition, chemical vapor deposition, and modern epitaxial techniques like molecular beam epitaxy.