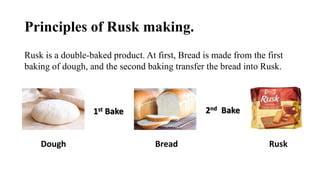

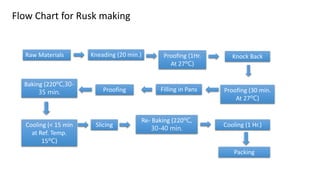

The document provides an overview of rusk production, detailing the ingredients, preparation process, and nutritional information. It outlines the steps involved in making rusk, including mixing, kneading, proofing, baking, cooling, and re-baking, while also highlighting common problems and equipment used in the process. Additionally, safety precautions during production are emphasized alongside a nutritional breakdown of rusk per 100g.