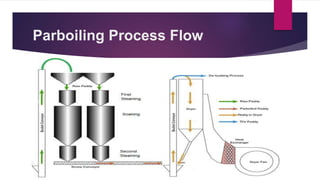

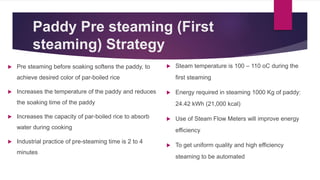

The document discusses the process of parboiling rice. It begins by explaining that parboiling involves partially cooking rice through steaming to gelatinize the starch. This process increases rice's nutrients and makes dehulling easier. The advantages of parboiling include higher rice recovery and more nutrients compared to raw rice. The process involves pre-steaming, soaking, post-steaming, drying, and tempering the rice. Key factors that affect quality are soaking time/temperature, steaming parameters, and drying time/temperature. The document provides details on strategies to optimize each step for higher efficiency and quality of parboiled rice.