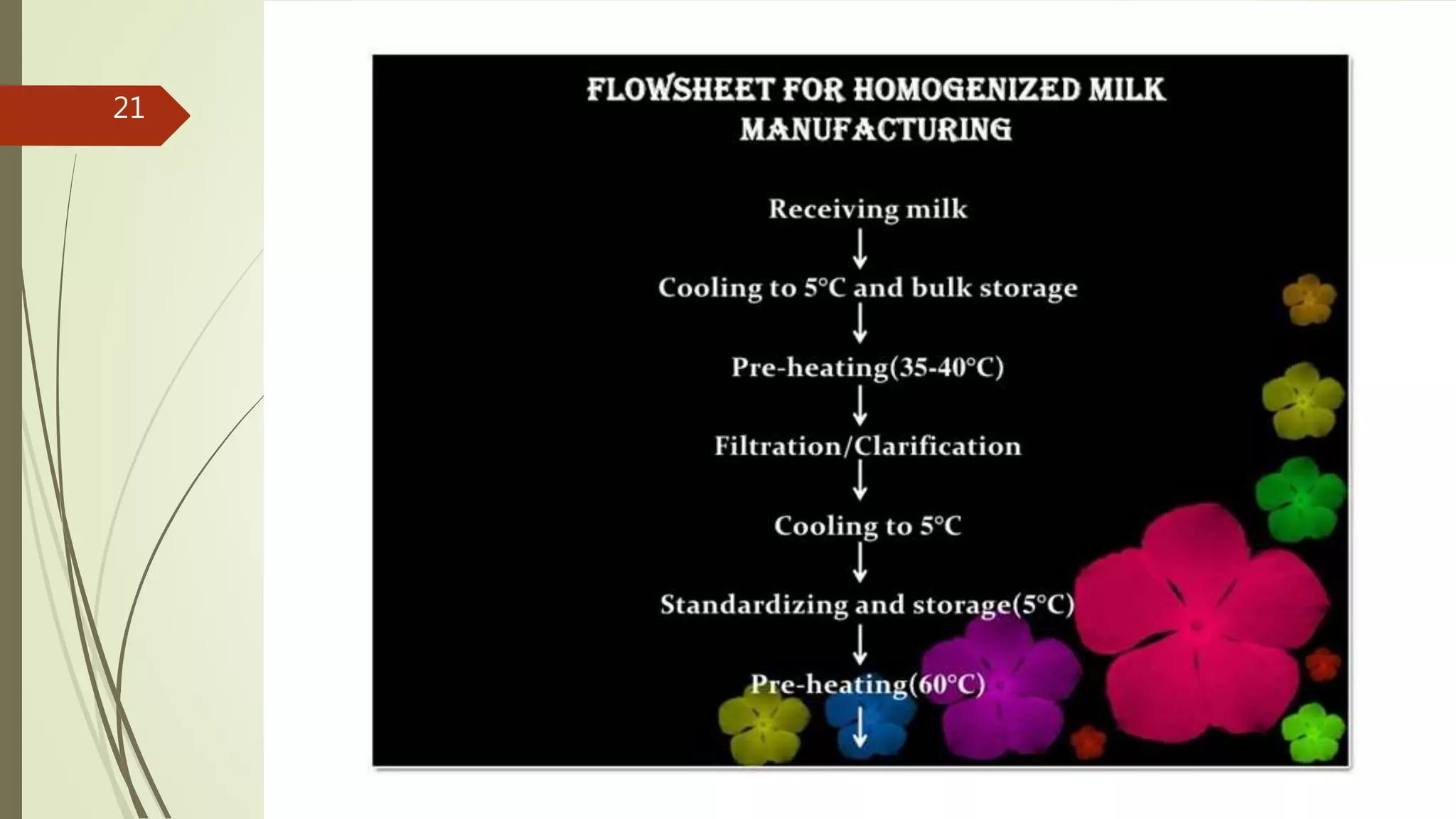

This document discusses homogenized milk. It begins by defining milk and its basic composition of water, lactose, fat, protein and minerals. The process of homogenization is then explained, which involves passing milk under high pressure through a small opening to break up fat globules into smaller sizes. This prevents cream from separating out and gives milk a smoother consistency. The advantages of homogenized milk include preventing fat separation, easier digestion and a longer shelf life. However, some argue that homogenization can negatively impact nutrient absorption and potentially increase health risks.