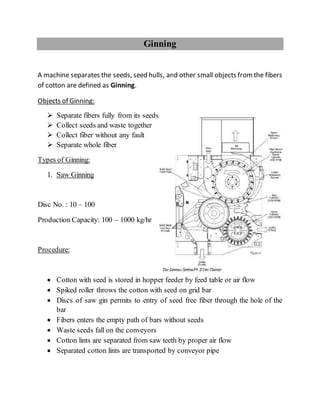

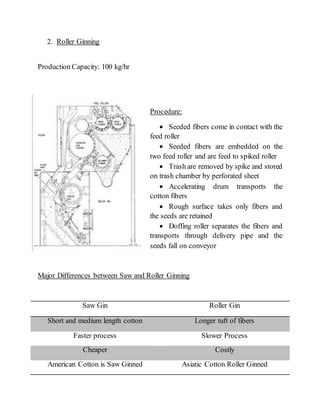

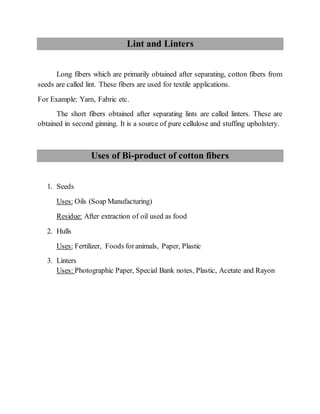

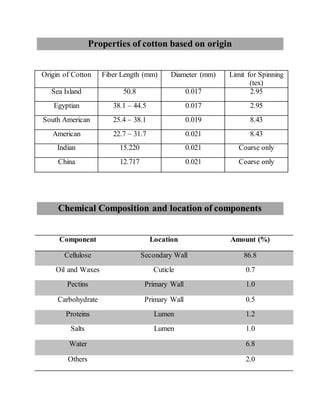

Cotton fiber grows in protective capsules around cotton plant seeds. Cotton has many desirable characteristics including softness, absorbency, color retention, printability, and strength. Cotton fibers are classified based on plant species, length, color, quality, and country of origin. The top cotton producing countries are India, China, the US, Pakistan, Brazil, and Turkey. Cotton requires a tropical or subtropical climate with sufficient rainfall and sunshine to cultivate. The cultivation process involves planting seeds, growing bolls, harvesting, and ginning to separate fibers from seeds. Ginning is done by saw or roller machines. The long fibers are called lint and are used for textiles, while short fibers are called linters and used