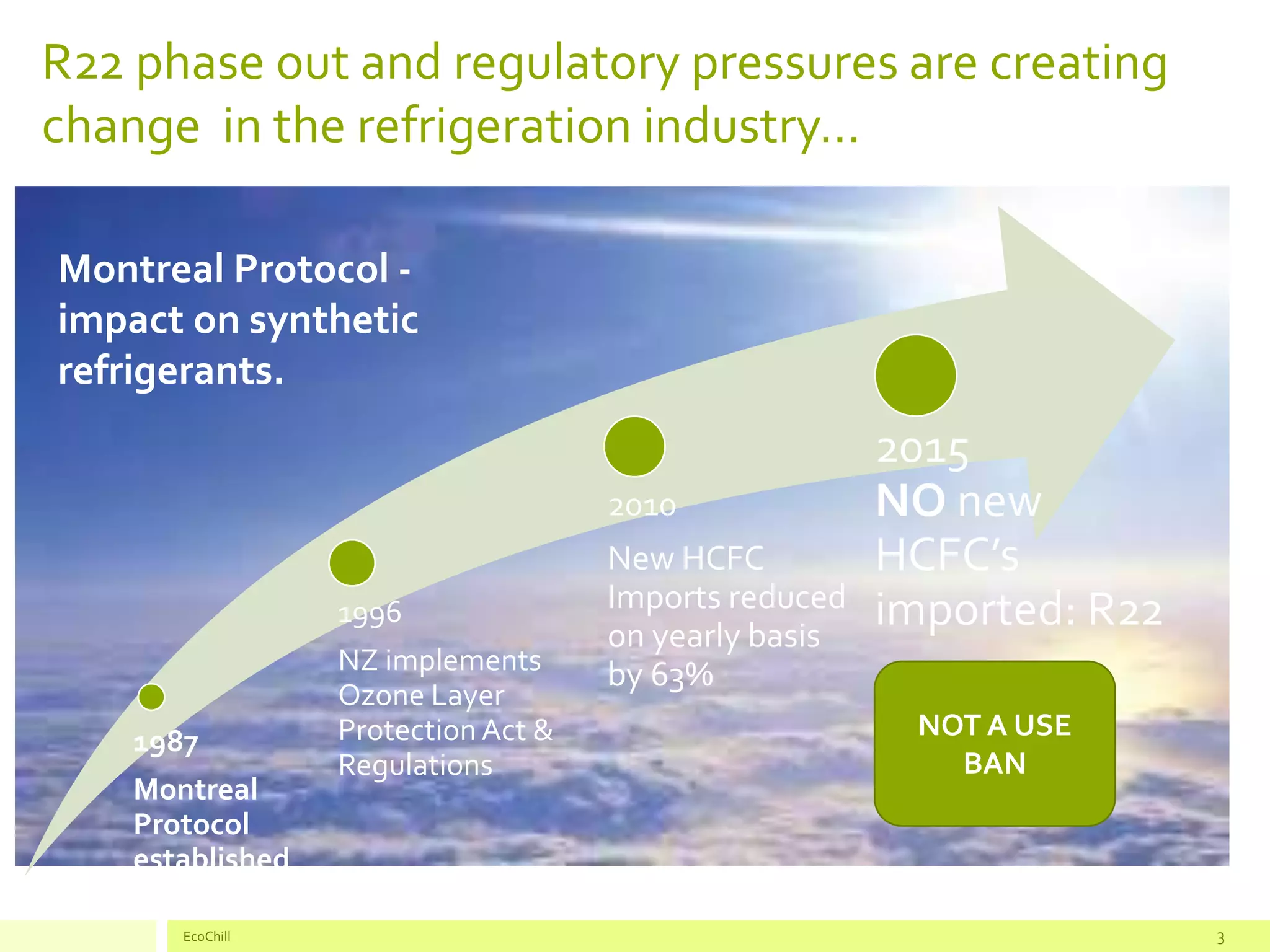

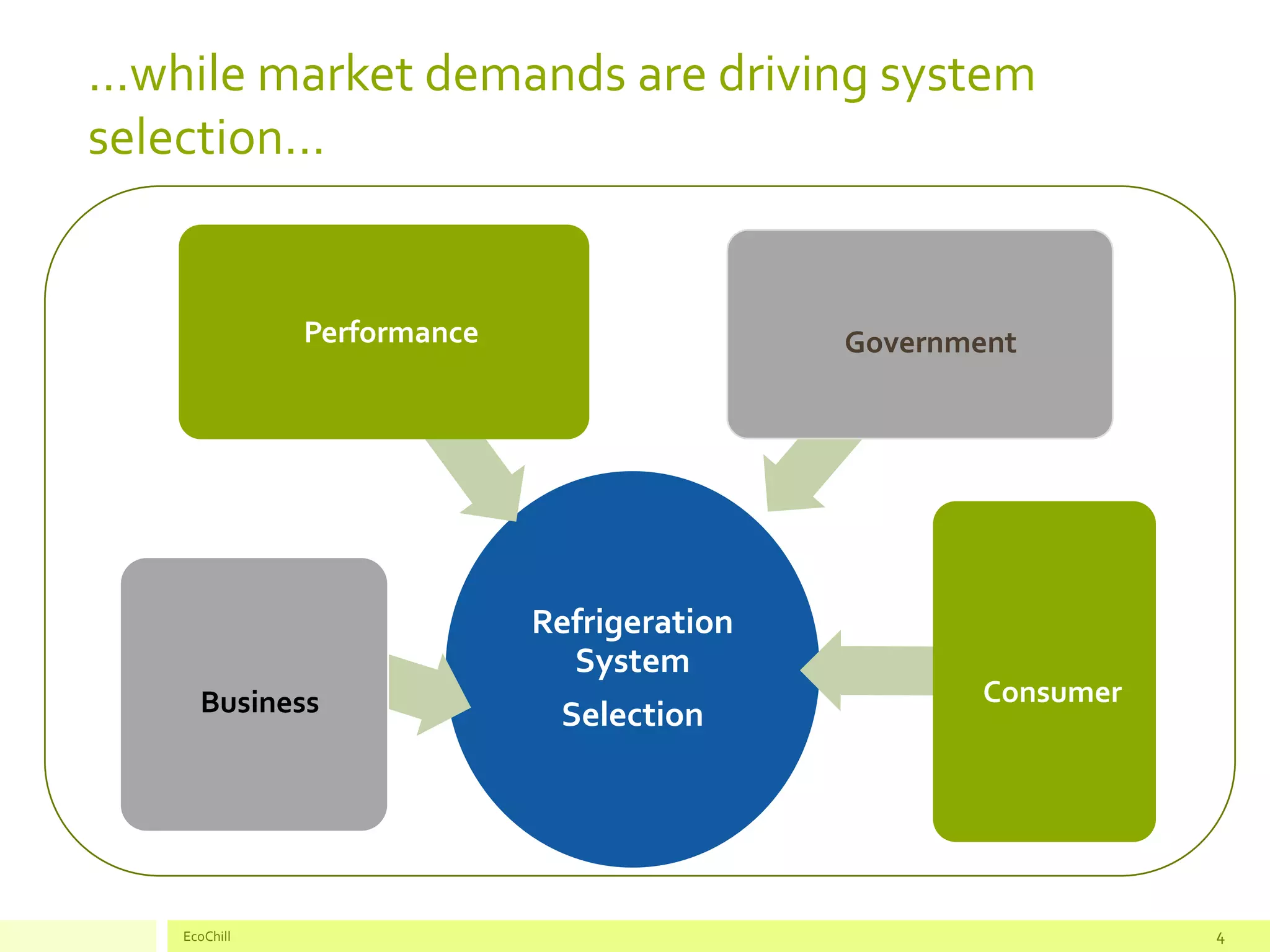

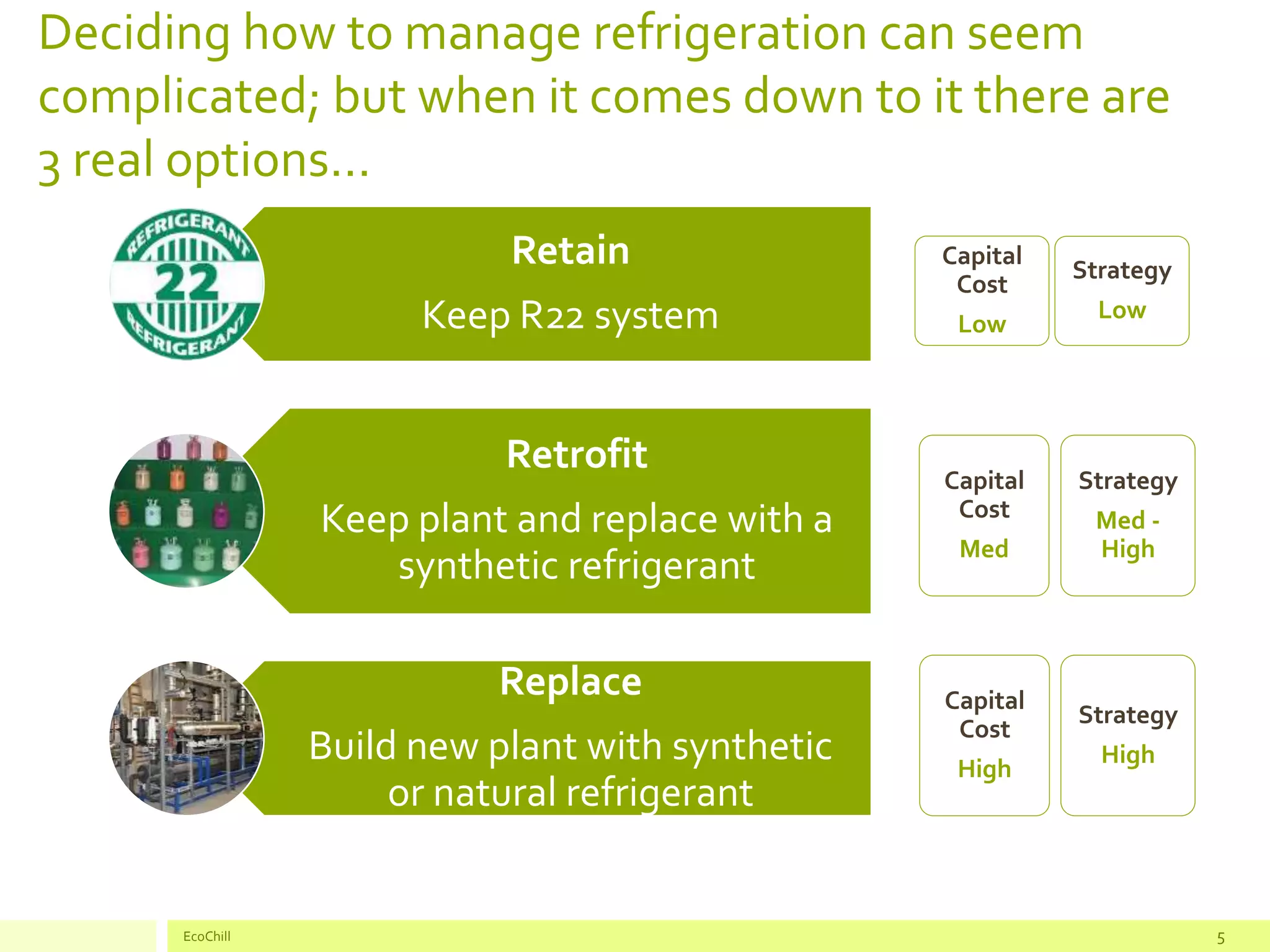

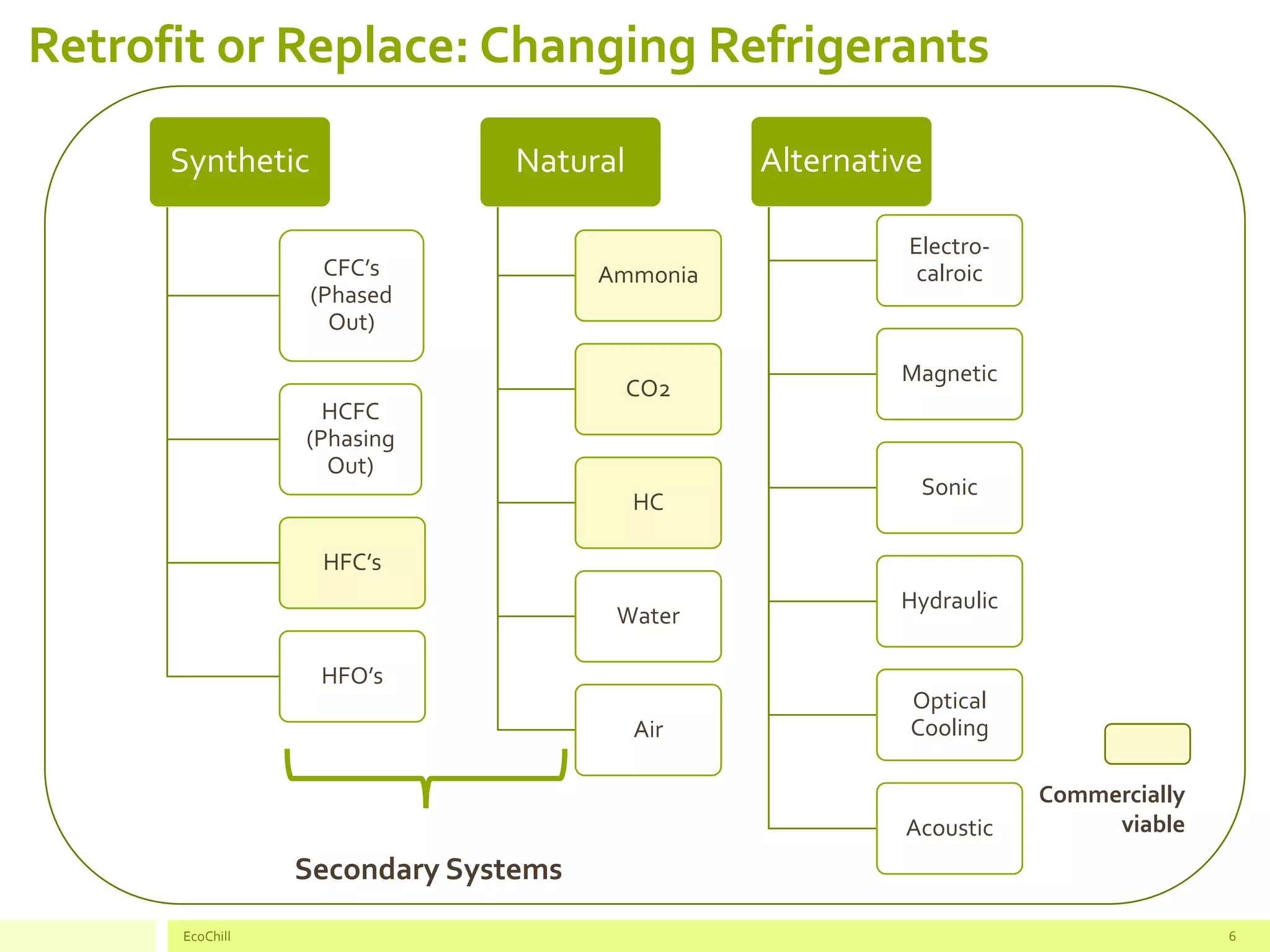

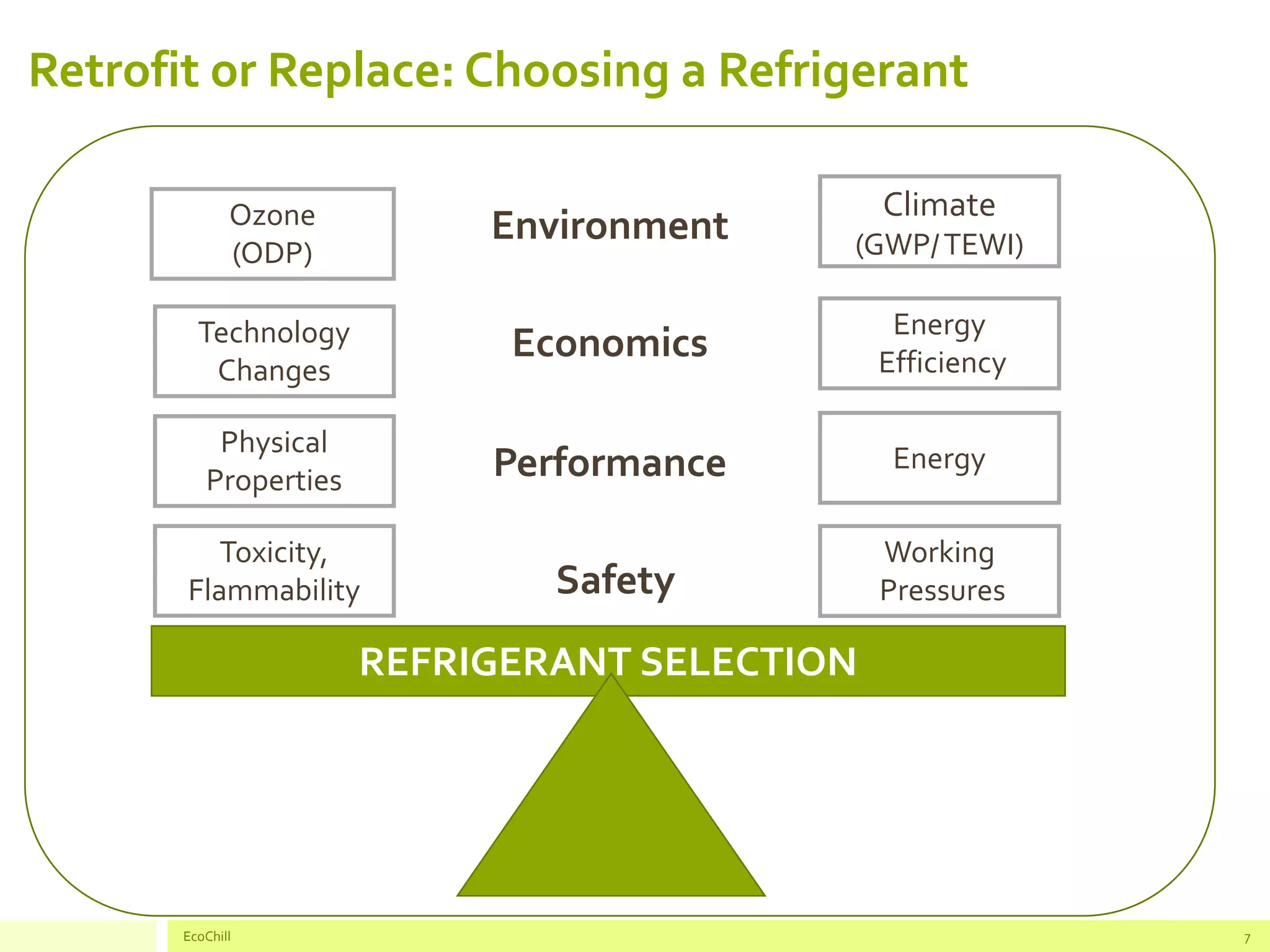

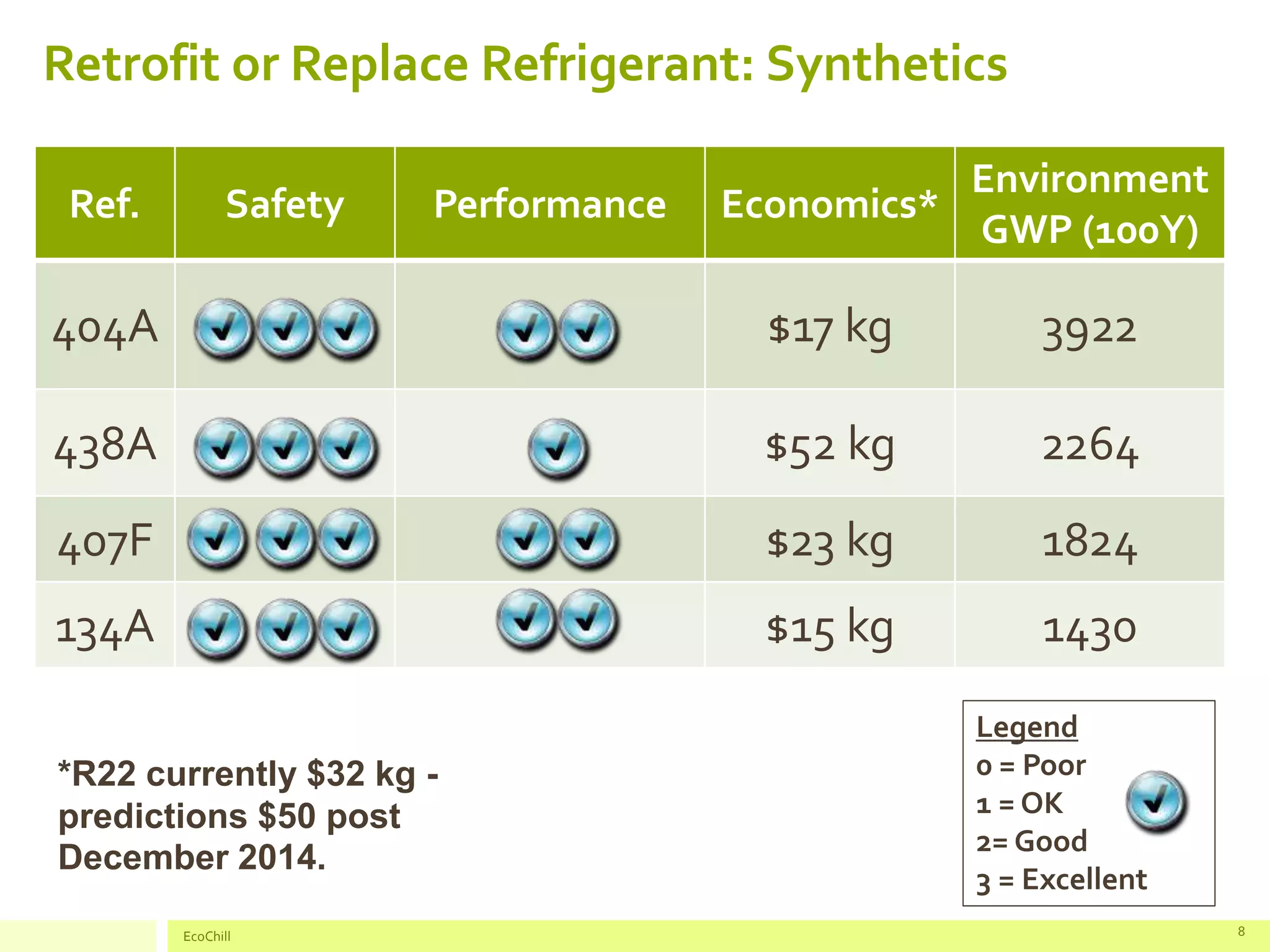

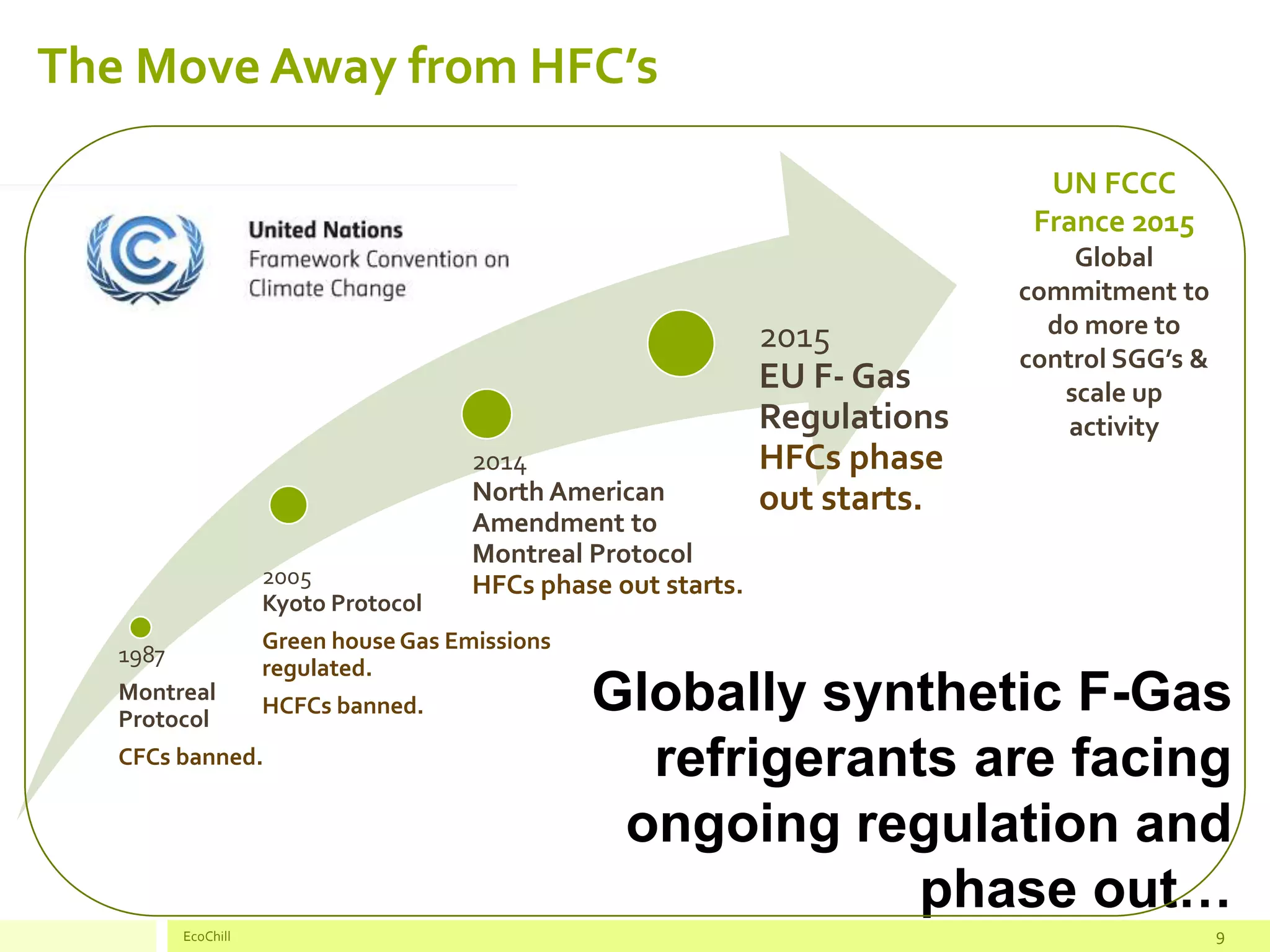

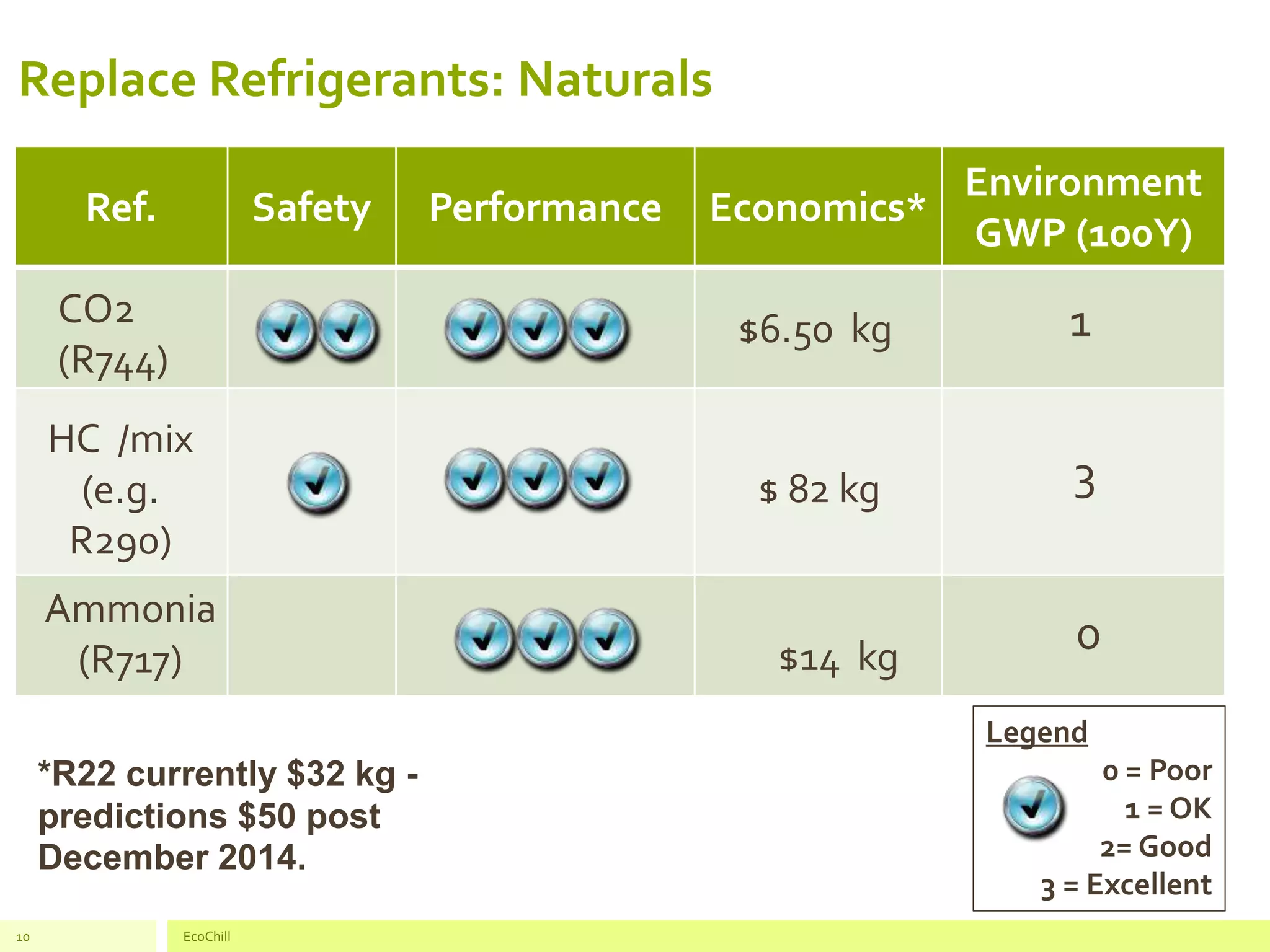

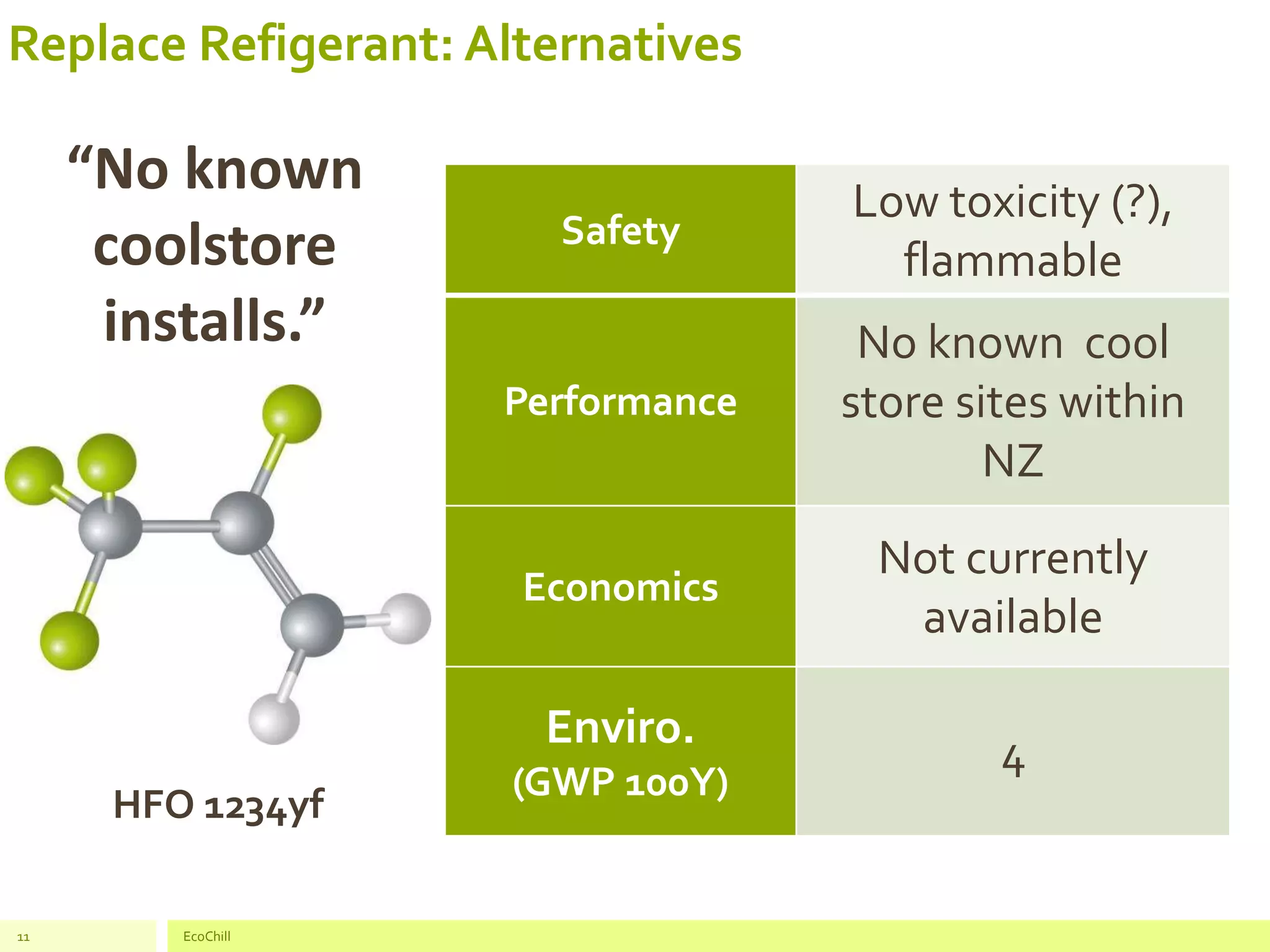

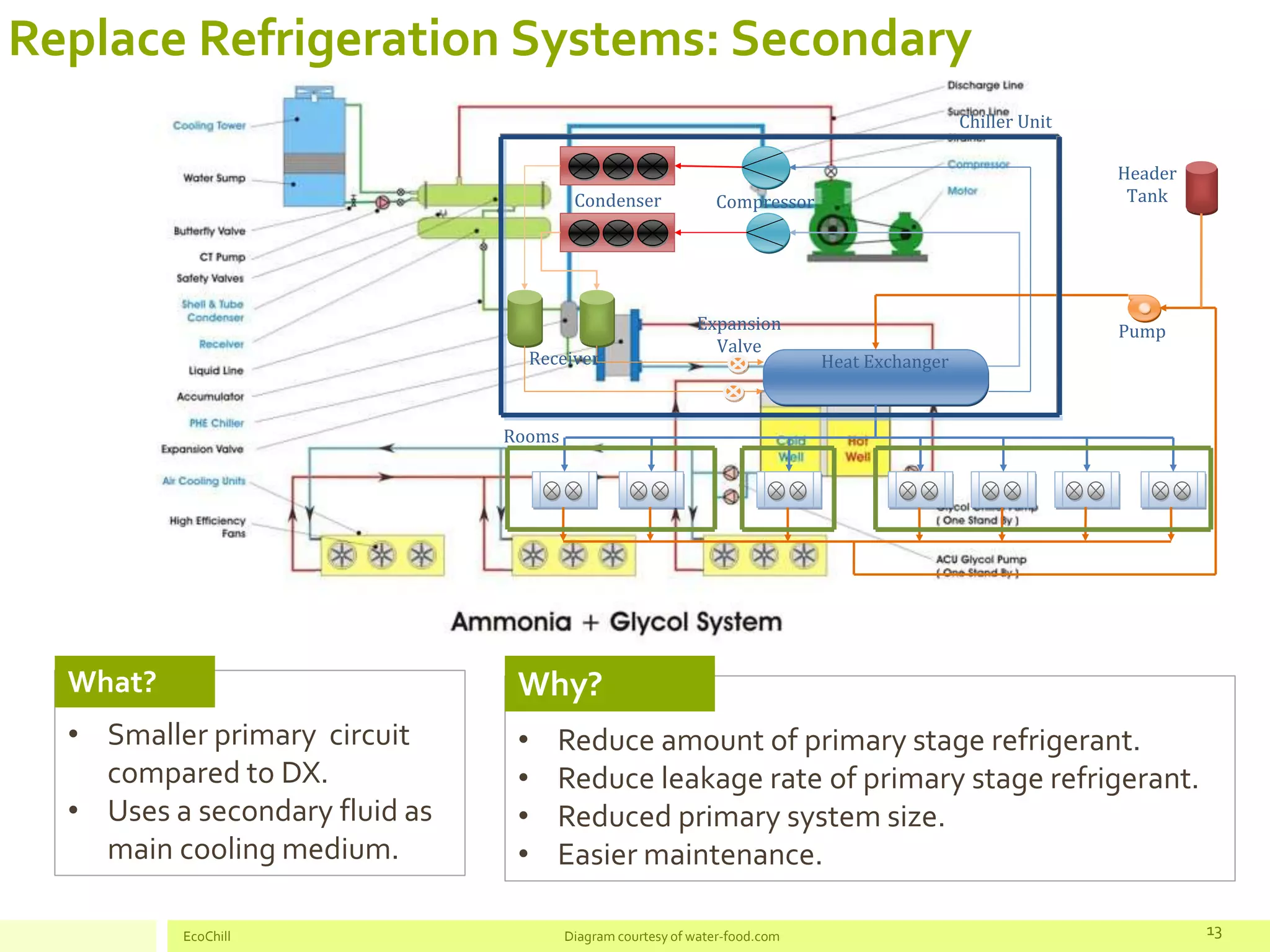

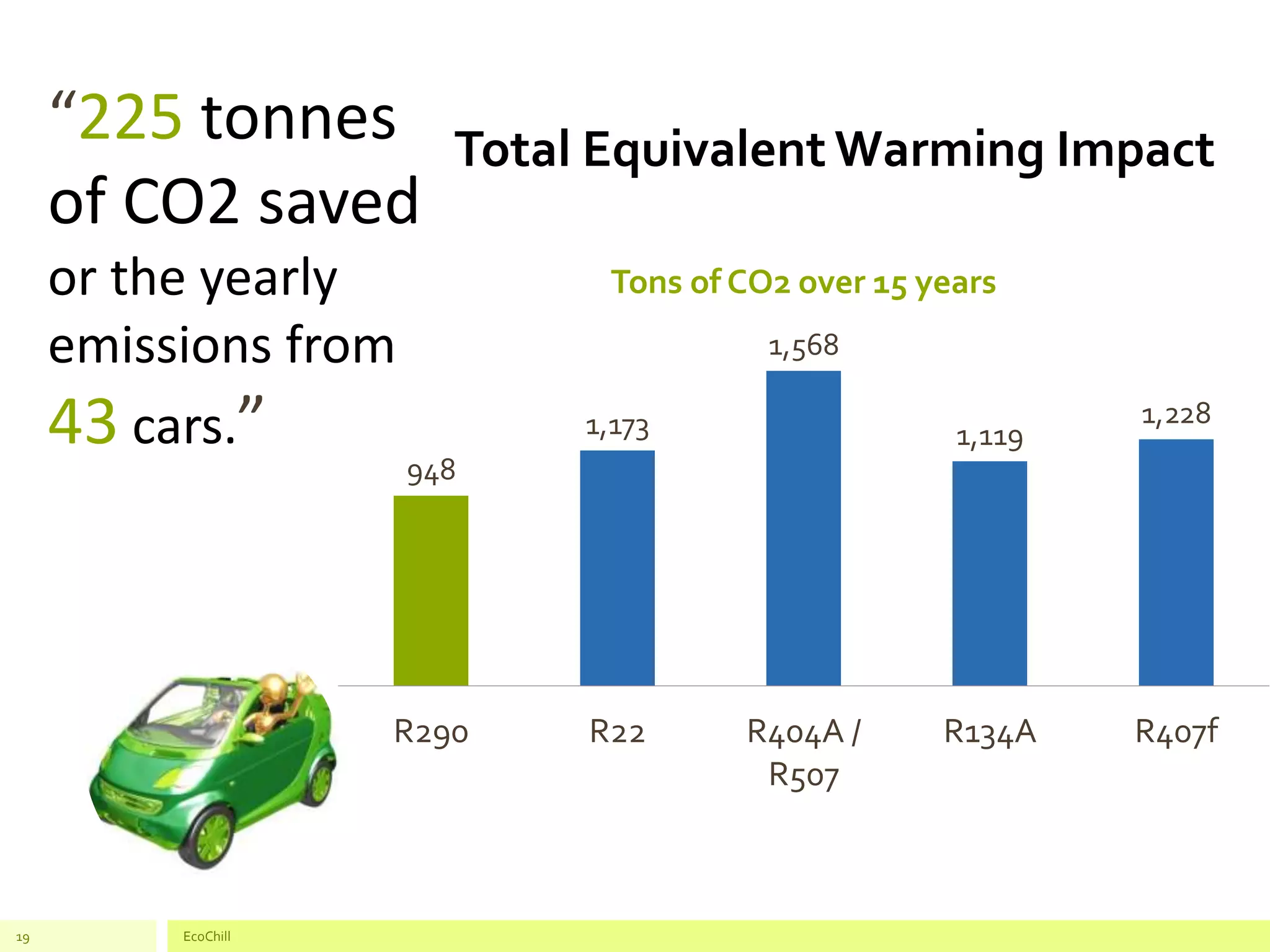

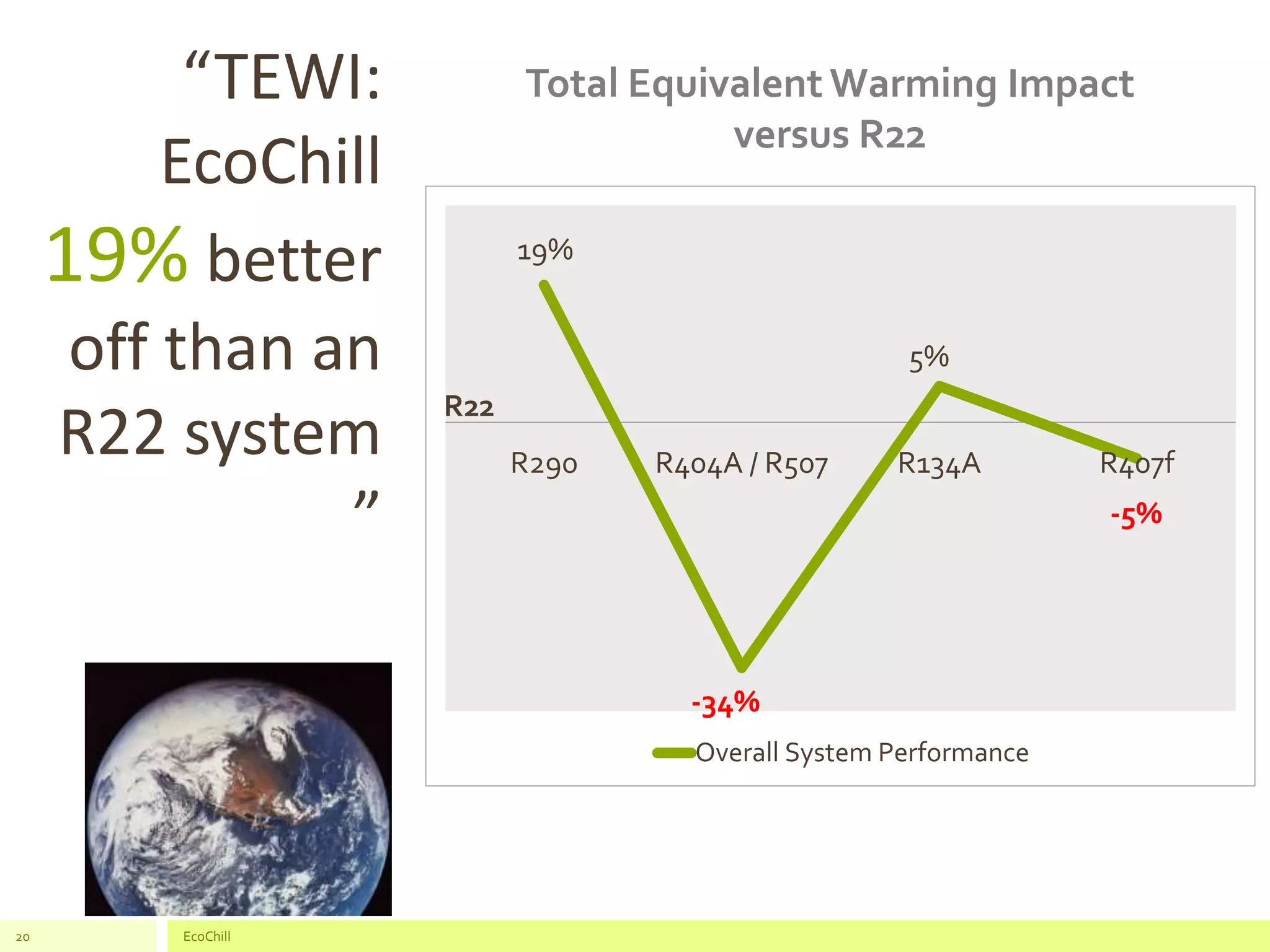

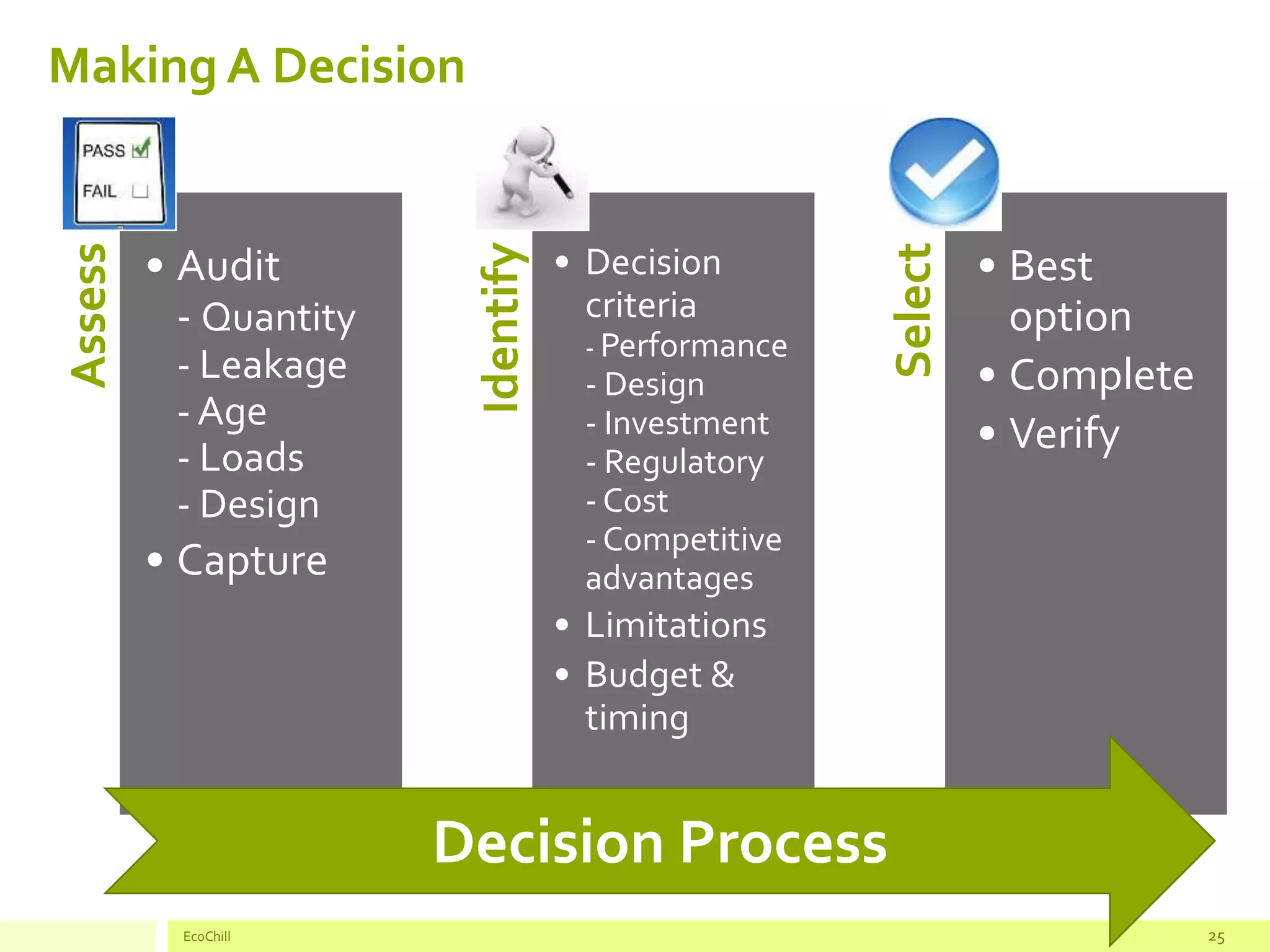

The document discusses the transition of refrigeration systems in light of the phase-out of R22 refrigerant due to environmental regulations, particularly following the Montreal Protocol. It outlines the options for businesses regarding their refrigeration systems, including retaining, retrofitting, or replacing them with synthetic or natural refrigerants. The document also emphasizes the importance of evaluating safety, performance, economics, and environmental impact when making refrigerant decisions.