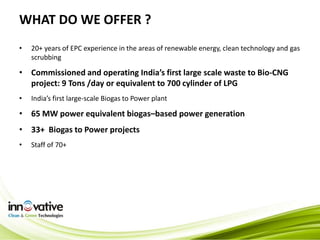

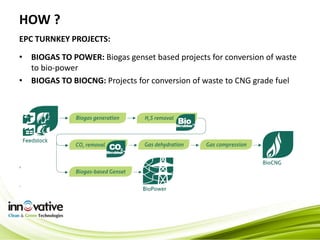

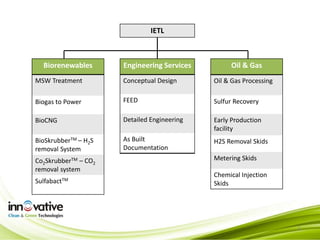

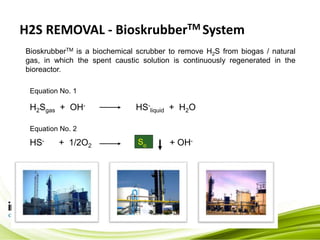

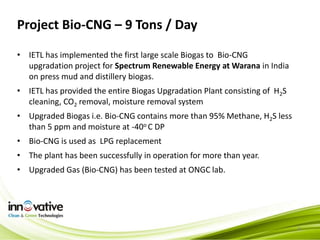

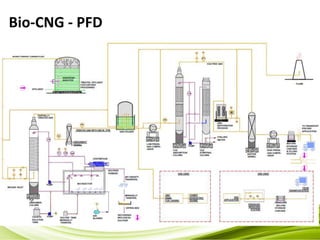

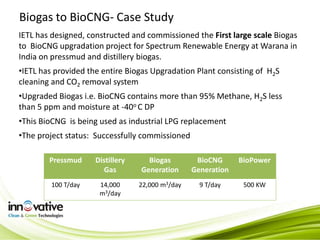

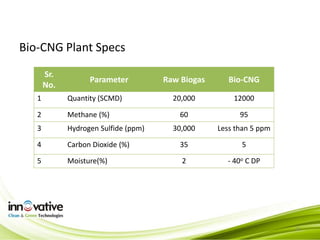

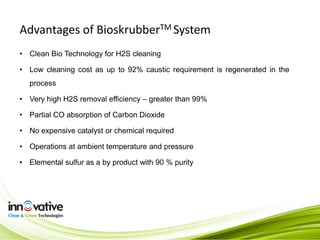

IETL is an ISO-certified company that provides biogas upgrading and bottling technologies. It has over 20 years of experience in renewable energy projects. IETL offers turnkey EPC services for biogas to power and biogas to bio-CNG projects. It has commissioned India's first large-scale waste to bio-CNG plant that upgrades 9 tons of biogas per day from distillery waste to over 95% methane bio-CNG, meeting CNG fuel standards. IETL utilizes its proprietary Bioskrubber system to remove over 99% of H2S from raw biogas in a cost-effective biochemical process.