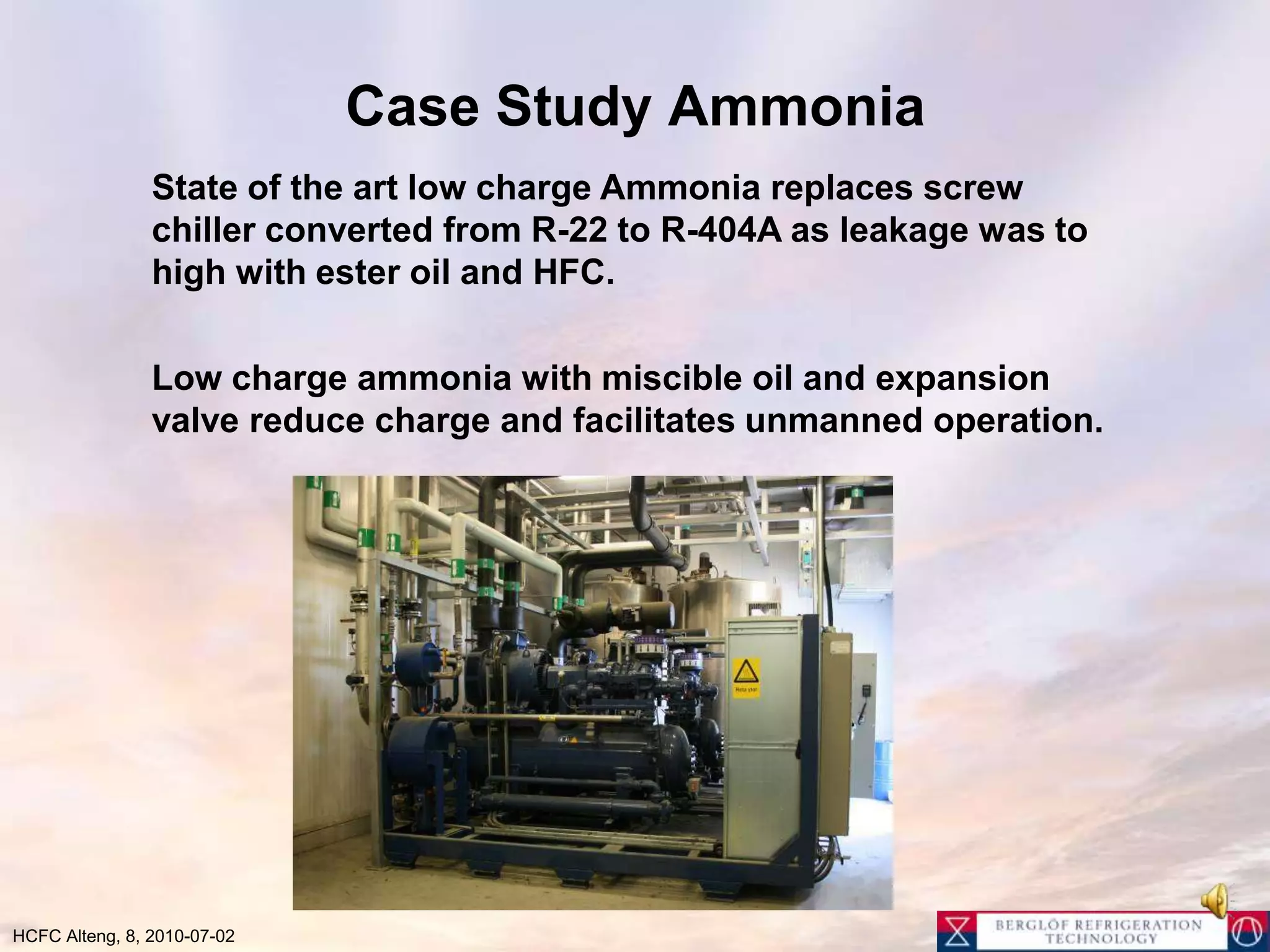

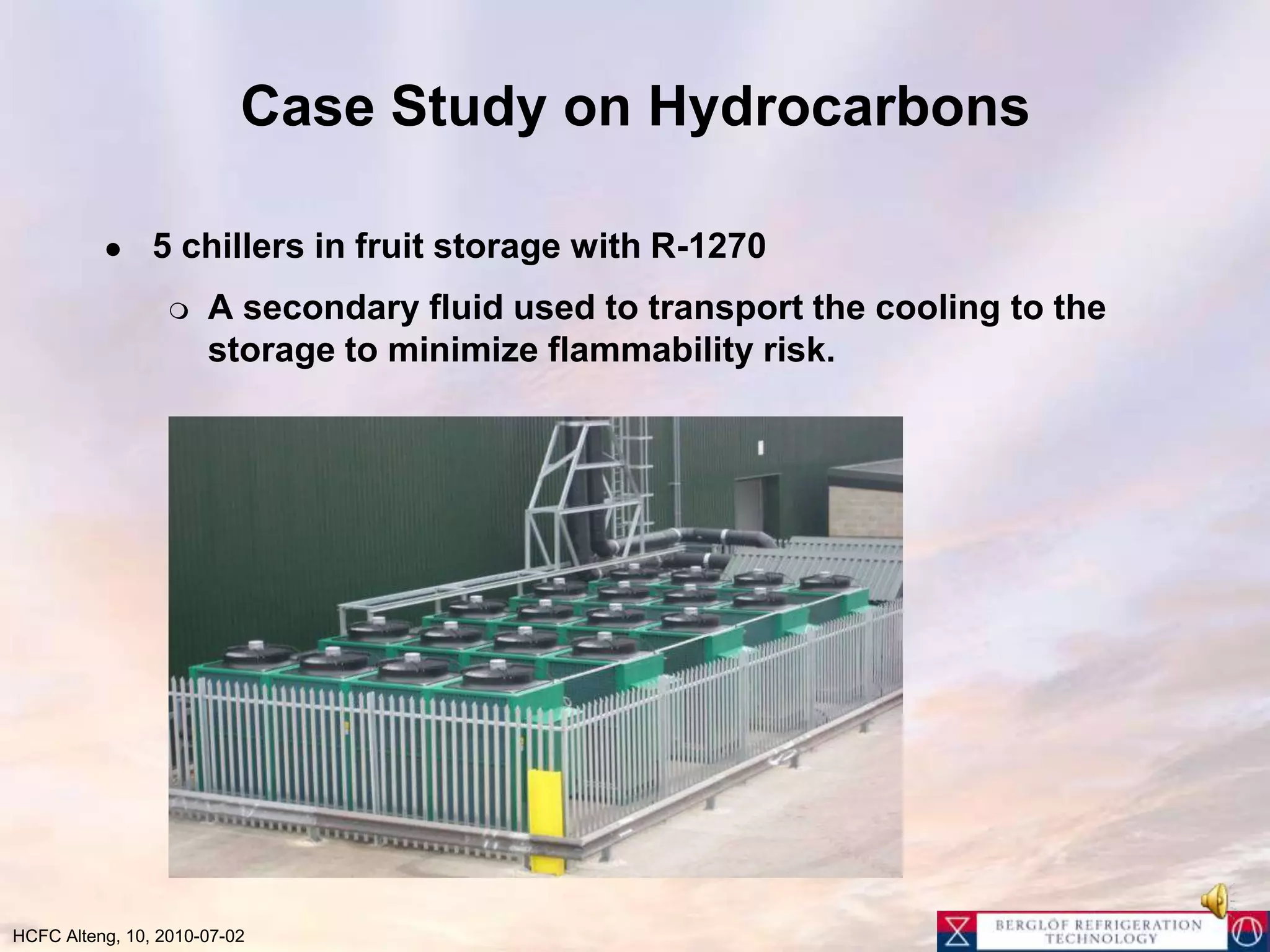

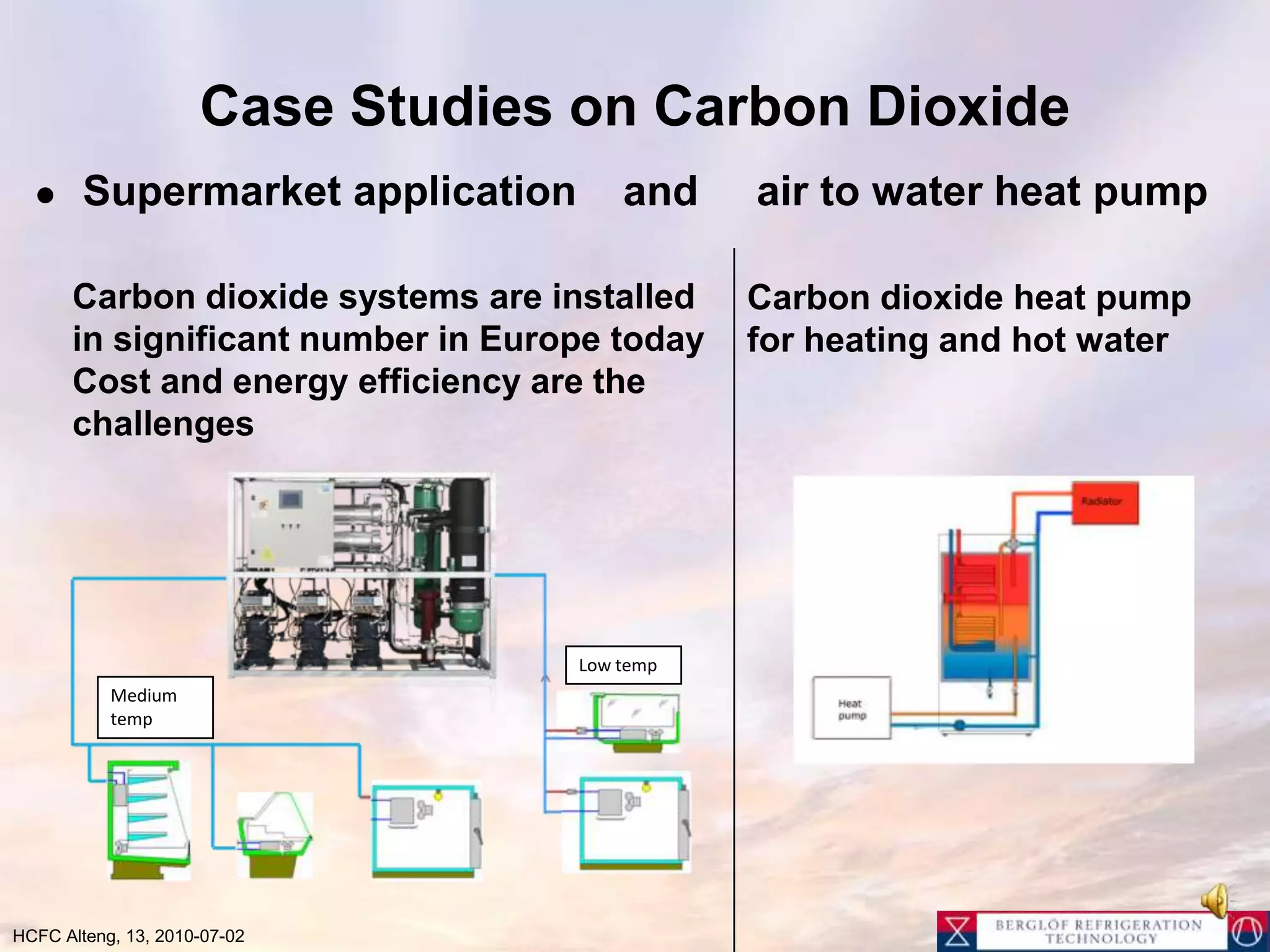

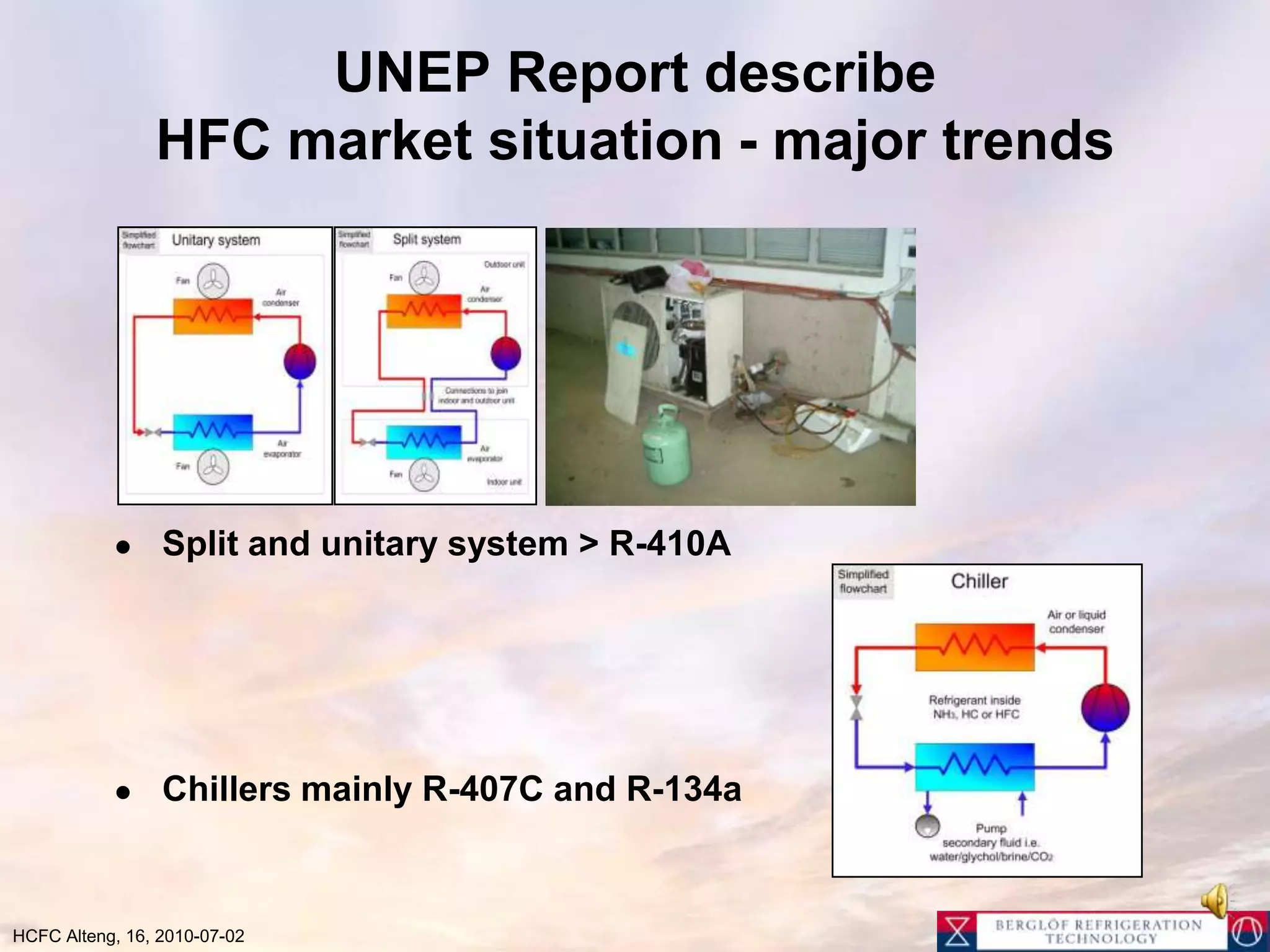

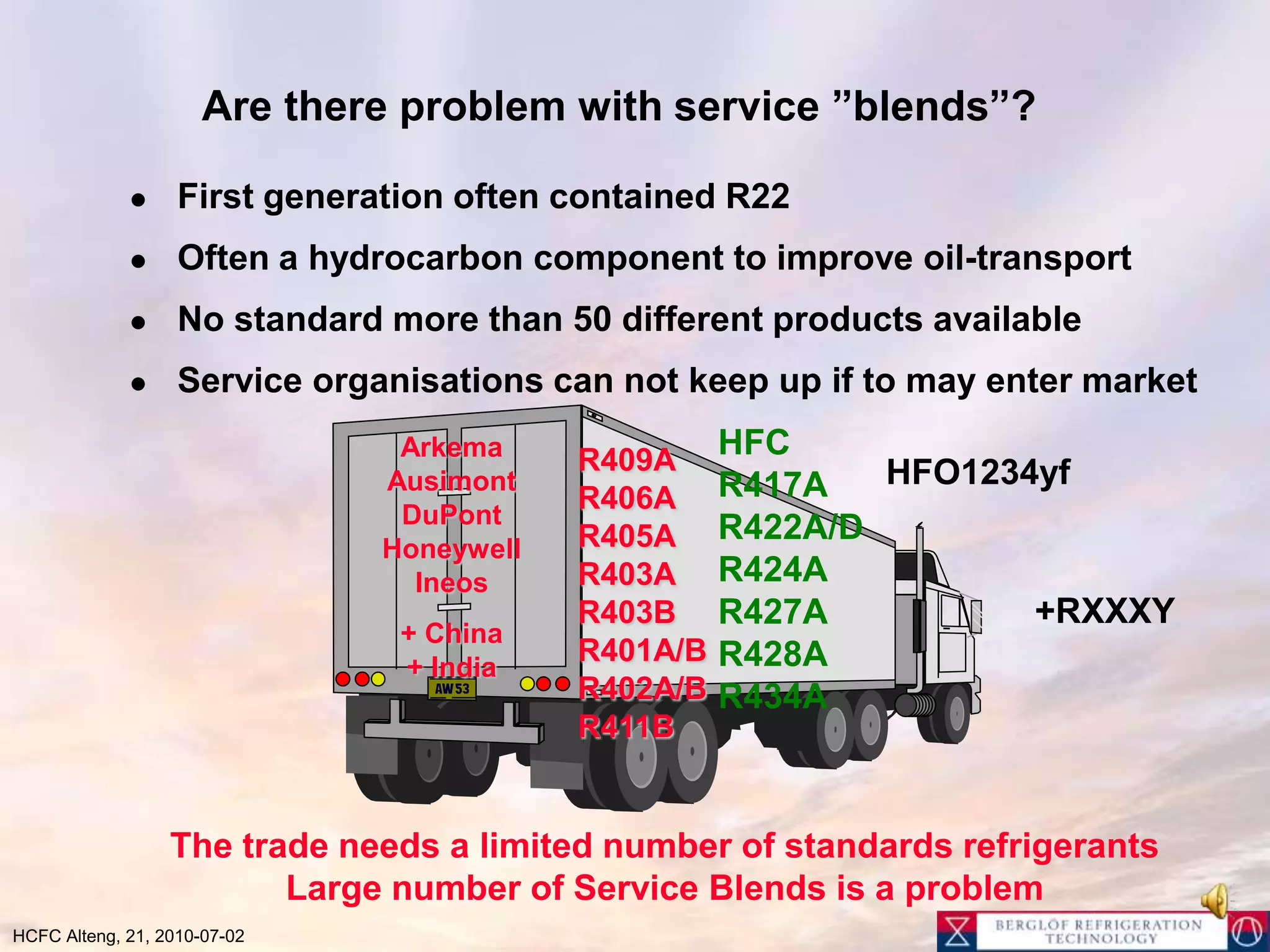

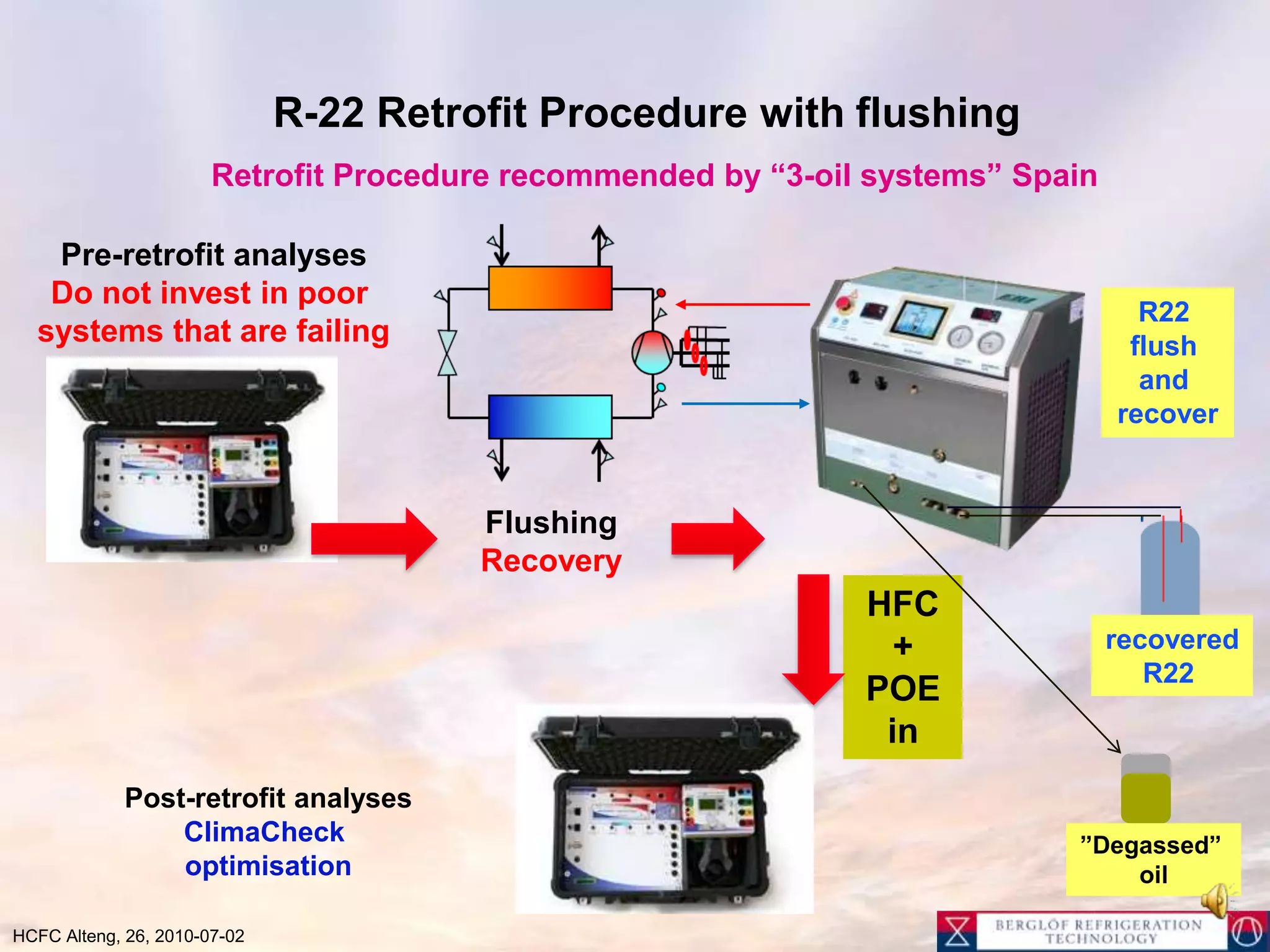

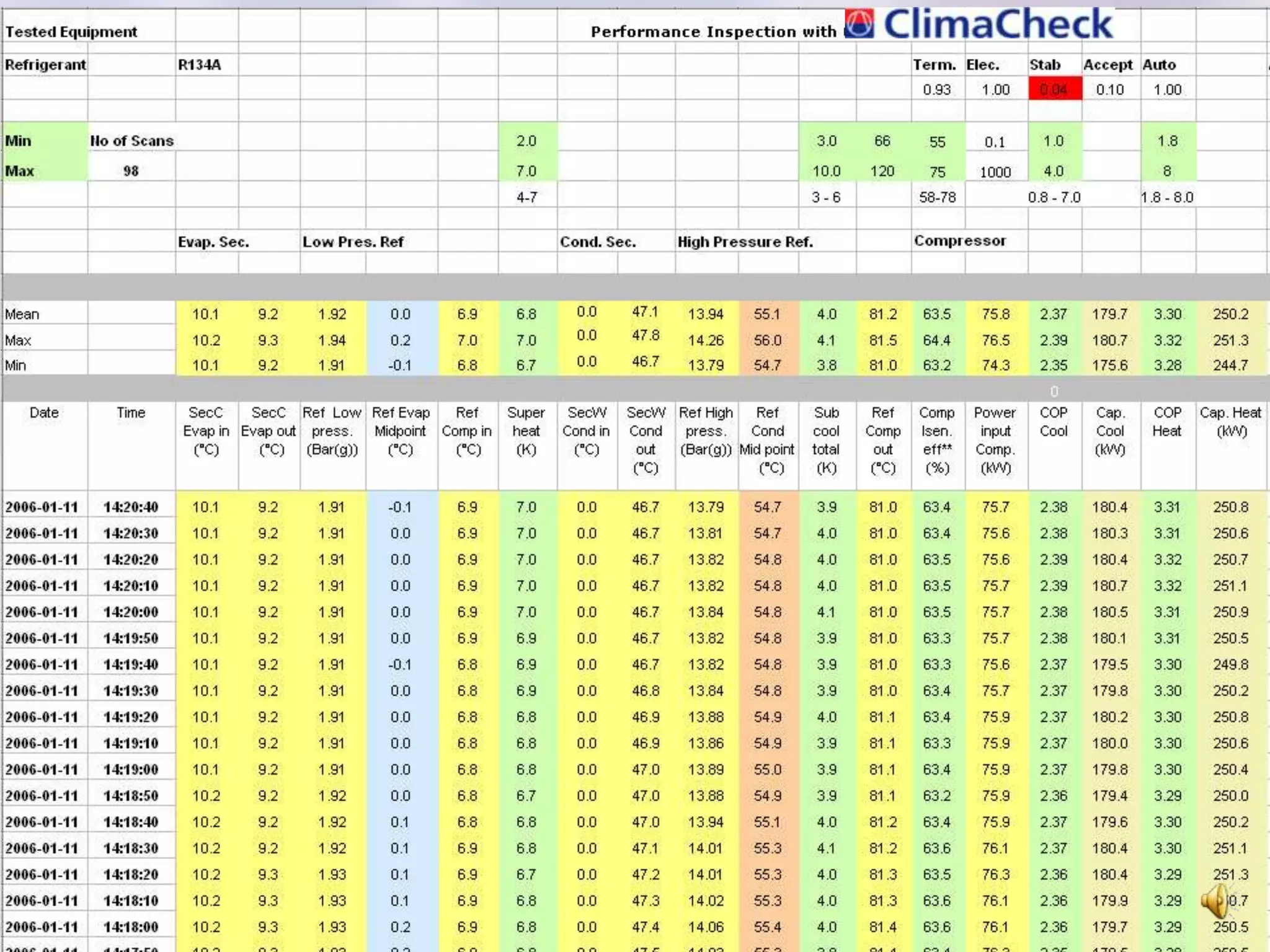

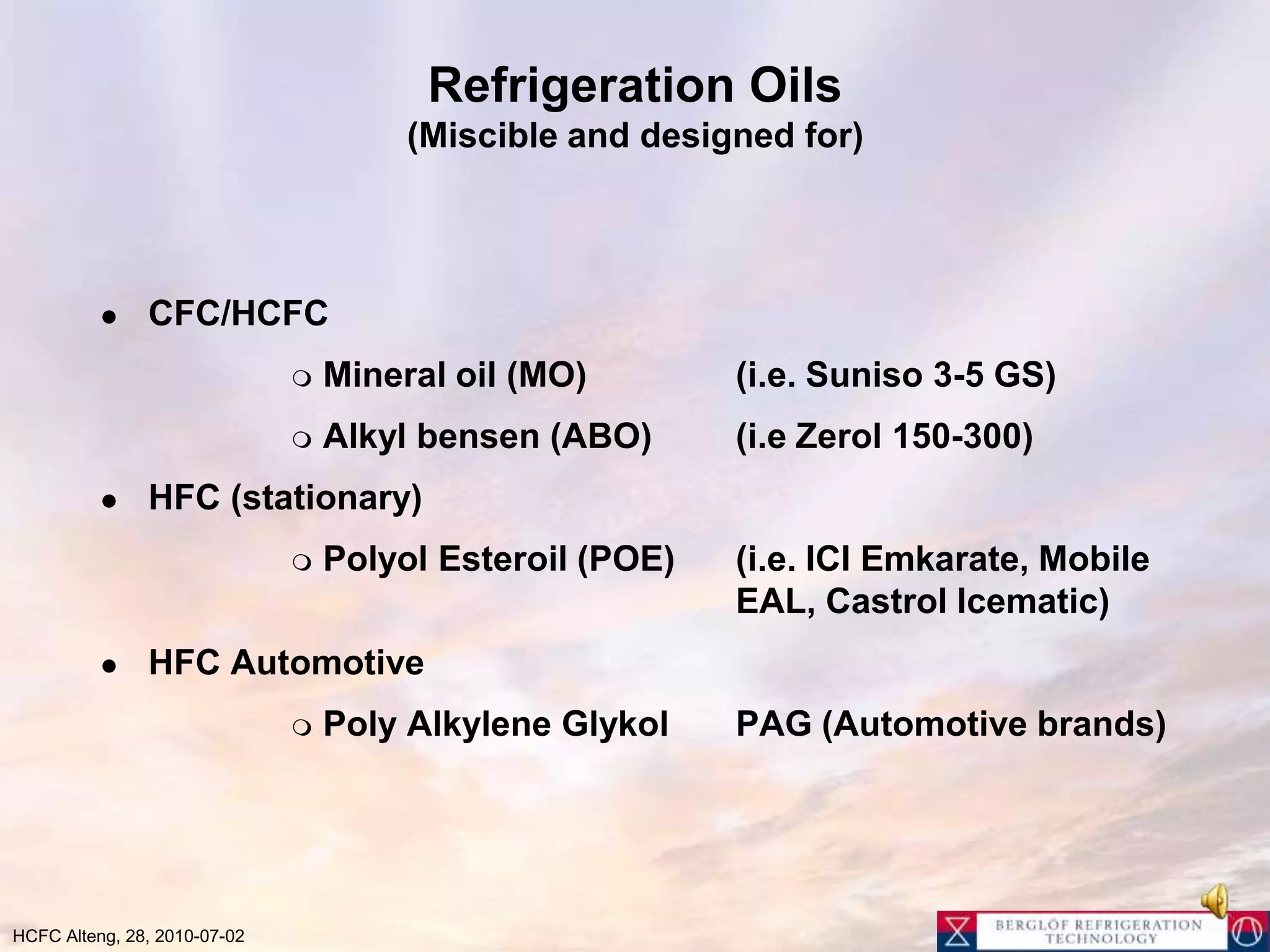

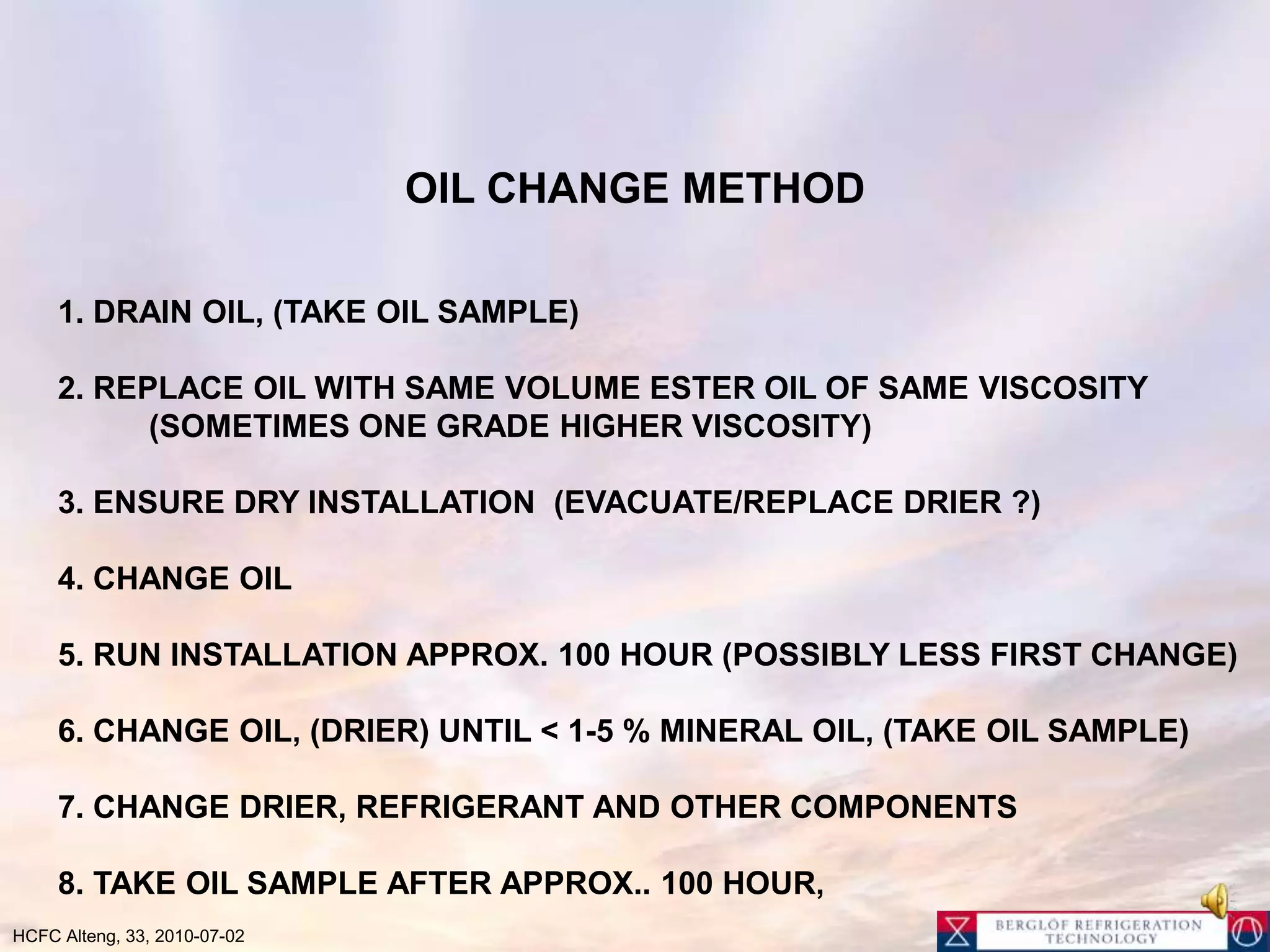

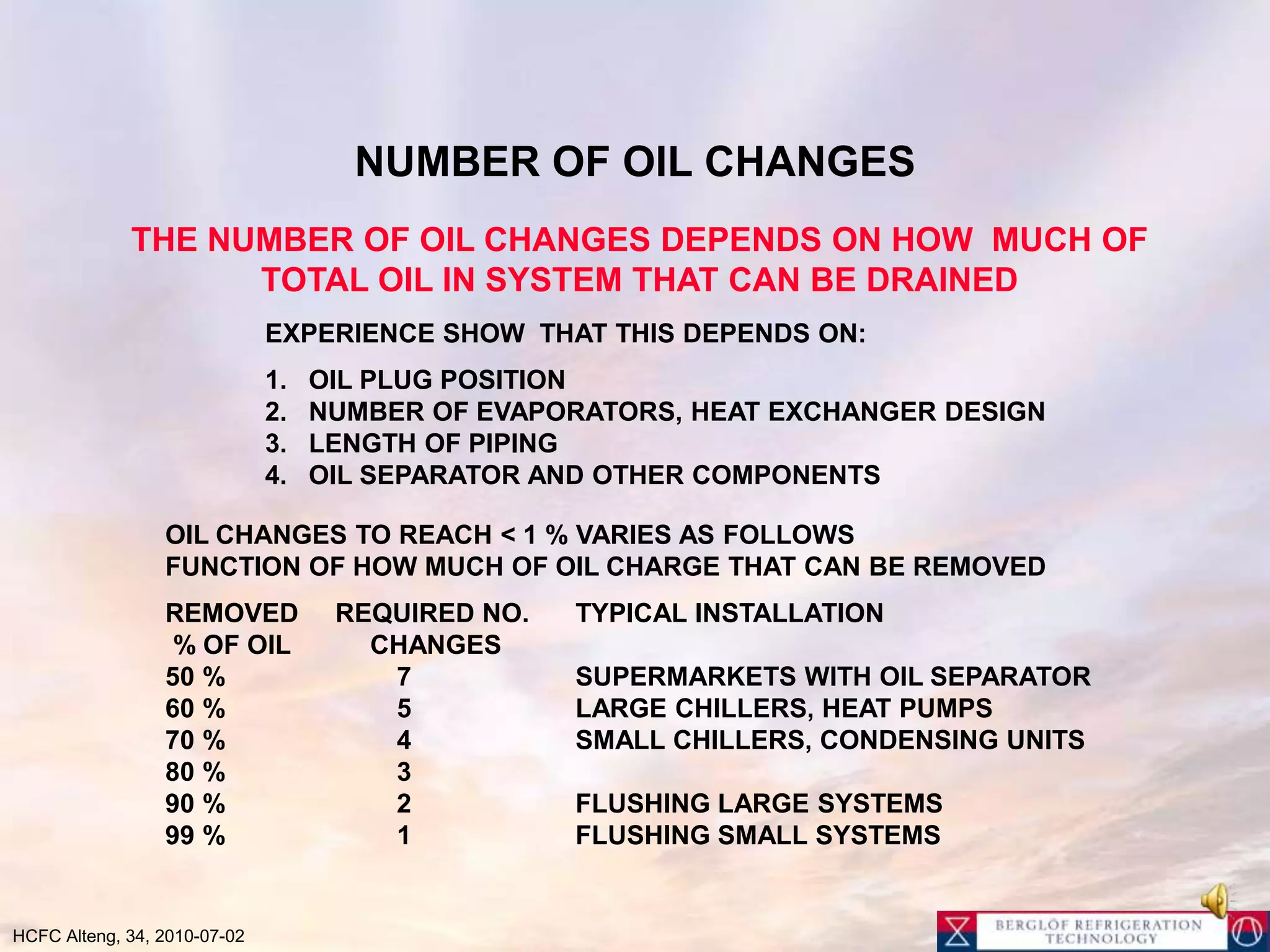

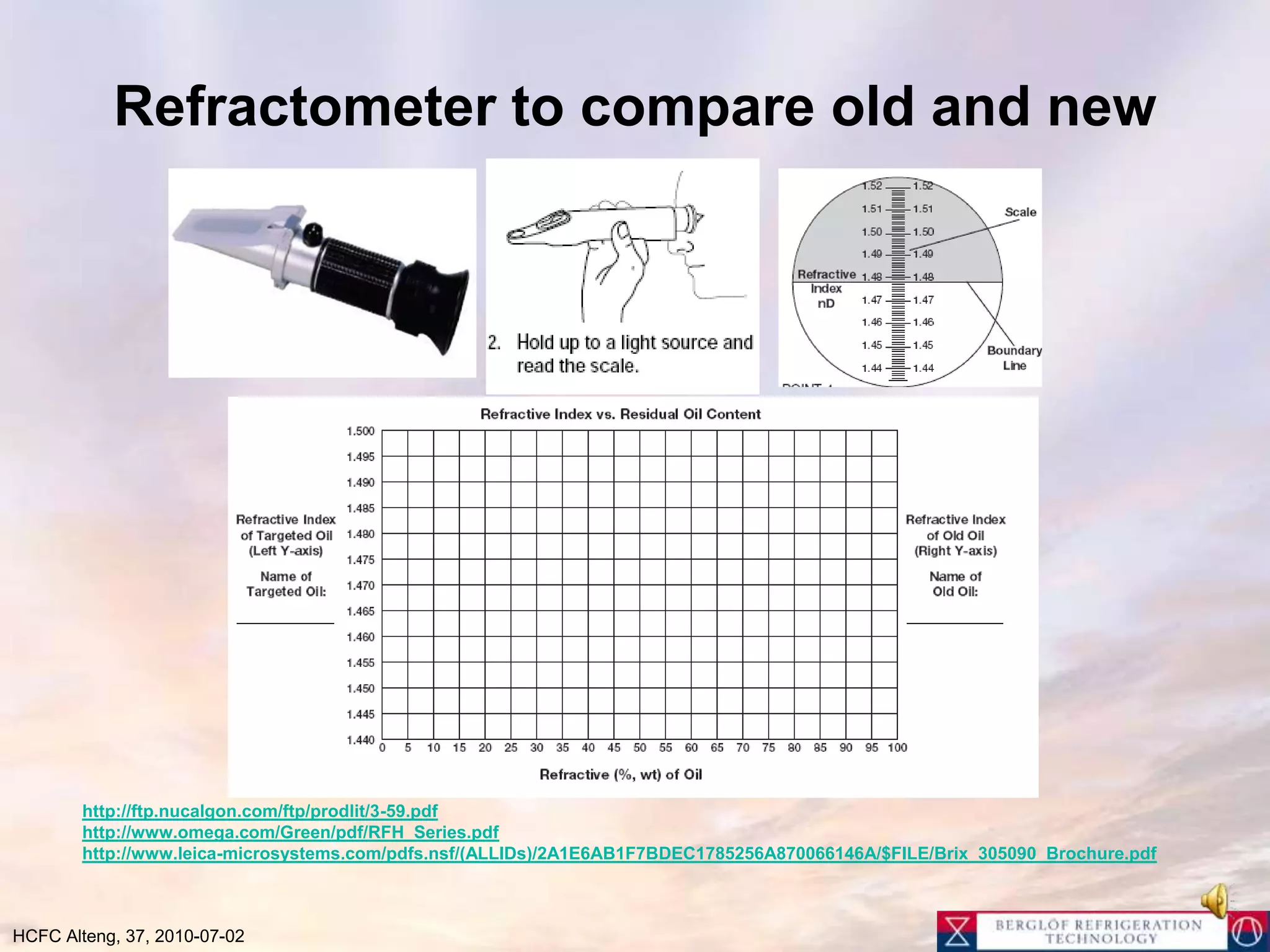

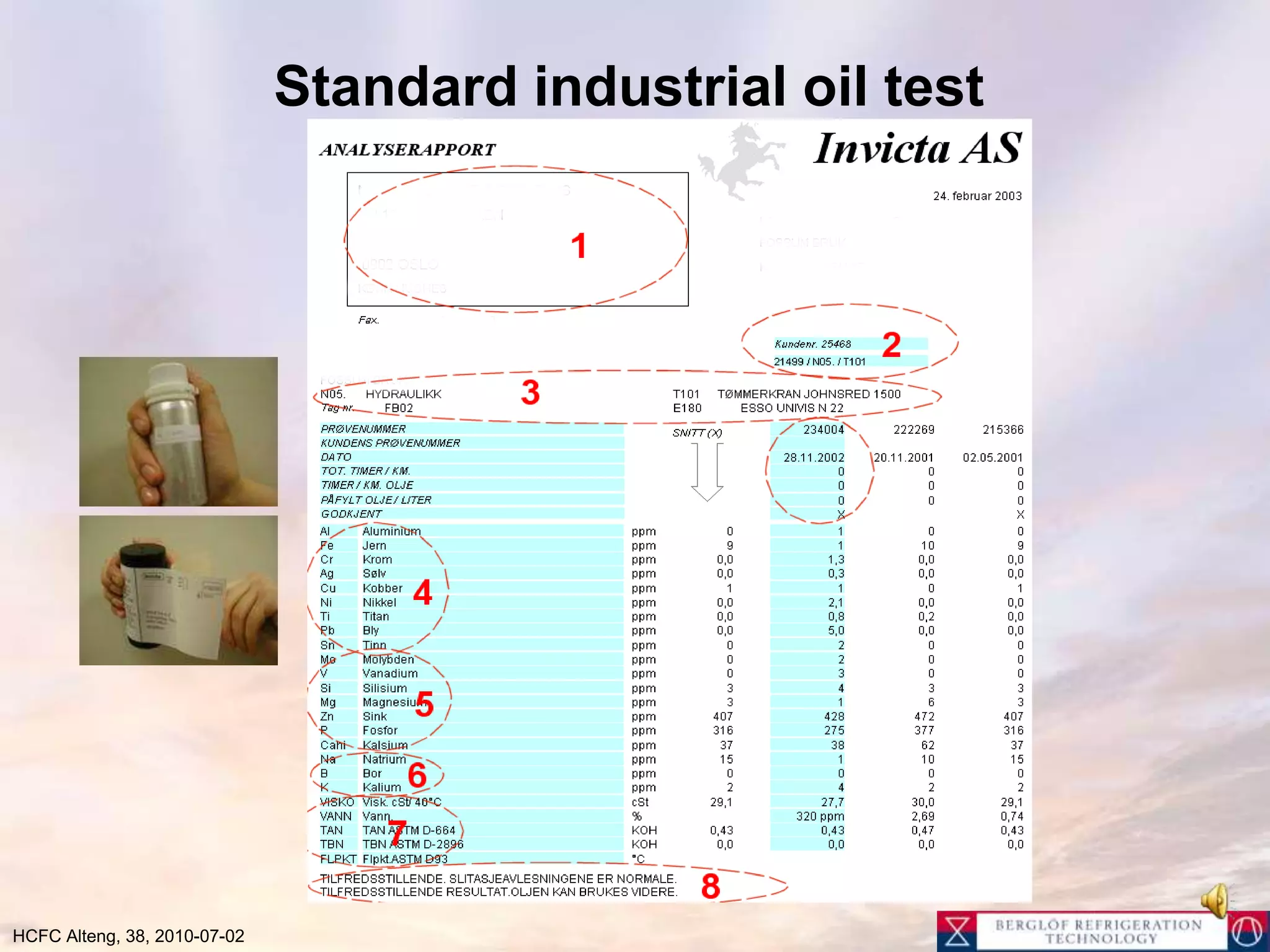

The document discusses the phase-out of HCFCs in refrigeration and air conditioning, exploring alternatives such as ammonia, hydrocarbons, carbon dioxide, and hydrofluorocarbons (HFCs). It highlights the need for careful evaluations of current systems, installation practices, and oil compatibility during retrofits. Additionally, it covers various replacement refrigerants, their properties, and the challenges associated with their use and integration into existing systems.