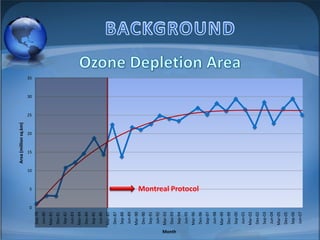

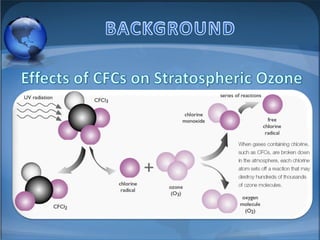

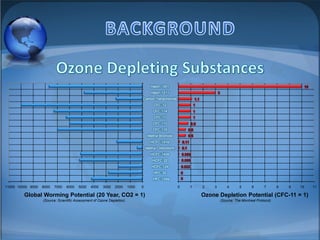

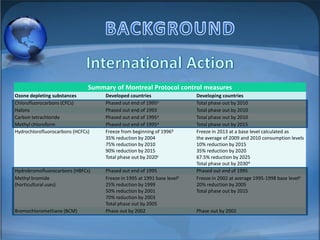

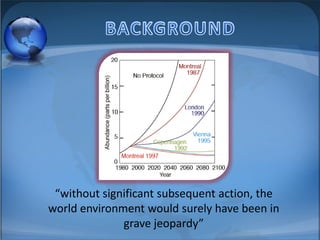

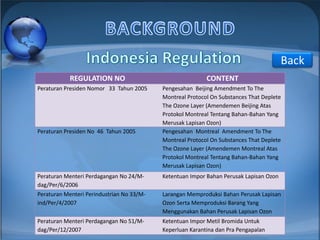

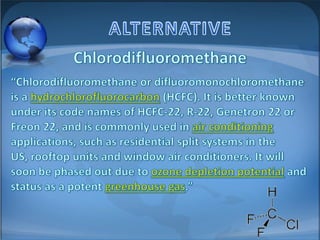

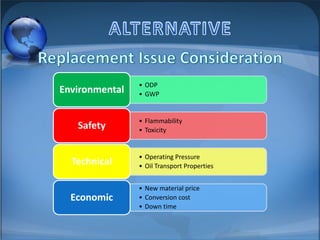

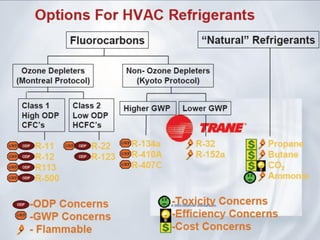

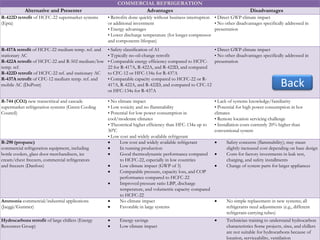

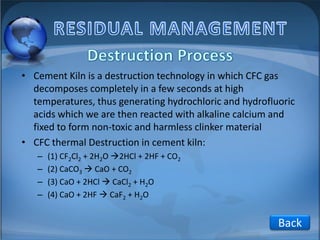

The document discusses the Montreal Protocol and its measures to phase out ozone-depleting substances, including various chemicals like CFCs, HCFCs, and methyl bromide. It outlines the scheduled reductions and phase-out timelines for developed and developing countries, emphasizing the environmental impact of these substances and the importance of regulatory actions. Additionally, it reviews alternatives to these substances in refrigeration, addressing their safety, efficiency, and potential environmental benefits.