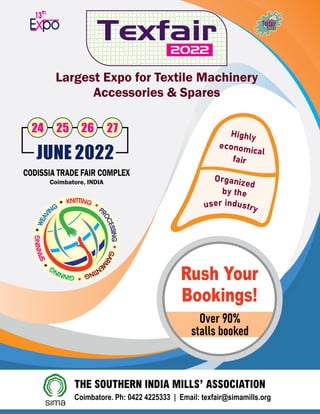

Smart textiles are textiles that can sense and react to environmental stimuli through the integration of functionalities into the textile structure. They are capable of responding to electrical, thermal, chemical, magnetic or other stimuli. Smart textiles find applications in clothing that can provide interactive reactions by sensing signals, processing information, and actuating responses. Some key application areas of smart textiles include medical care through integration of sensors for health monitoring, protective clothing that can sense and respond to threats, and shape memory textiles that can change shape when exposed to heat. Research in smart fibres and textiles is advancing applications in various fields like healthcare, defense, sports and more.

![29 TVC | MARCH 2022

i. Dye needs to be first dissolved in SC CO2 and then

transported to the textile in placed in dyeing vessel.

ii. Dyes have Low solubility in SC CO2 resulting in low

dye concentration in dye solution.

iii. Low residence time of dissolved dye flowing through

the dyeing vessel, limits the contact, interaction of

textile material with dye molecules.

iv. Some part of dissolved dye which is flowing through

the ‘Dyeing vessel’ may not come in contact with

the textile surface. Also, Non-uniform flow / Chan-

nelling of SC CO2 solution through textile roll in dye-

ing vessel can lead to non-uniform contact and thus

non-uniform dyeing in large scale operation. Thus, it

may require special, complicated additional devices

to impart say rotational motion to the textile roll in

dyeing vessel, to improve the uniformity in dyeing.

v. Thus, only part of the available dissolved dye may

actually take part in SC CO2 dyeing to achieve de-

sired colour Intensity on textile material.

vi. The final shade of dyed cloth depends on the extent

of exposure as the shade keeps getting darker with

passage of contact time with fresh dye solution en-

tering the dyeing vessel, making it difficult to control

Batch to Batch variation.

vii.Mainly useful for applying dark shades with a single

colour at a time.

viii. All above limitations makes prior art SC CO2

dyeing process less versatile, slow and less efficient.

Hence, the objective of innovative work at DSPL was to

develop an improved dyeing process:

• To get uniform, reproducible interaction between

dye molecules and entire surface of textile material.

• To Improve rate of solubilisation of dye molecules in

Supercritical CO2 solvent to increase the rate and ef-

ficiency of SC CO2 dyeing process.

• To achieve easy scale-up to large scale dyeing while

maintaining desired uniform & reproducible colour

intensity on textile material.

• To get dyeing of the textile materials with a single

or multi-colours in various shades, patterns etc. in a

single step of dyeing operation.

Methods & Materials:

Details of Innovative SCF Dyeing Process from DSPL:

Our innovative process having Indian Patent no.

298213 [1] and United States of America Patent No. US

11015289 B2 [2], includes the following steps:

a. Making a dye solution: By mixing the dye material

and auxiliary chemicals with suitable solvent. We

preferably use water as a solvent for the convention-

al dyes along with the dispersing, levelling agents.

b. Pre-treatment: Pre-coating the surface of textile ma-

terial to be dyed with an optimum quantity of above

dye solution to obtain a dye coated textile material.

Any standard method of coating can be used such as

Roller coating, ink jet printing etc.

c. Supercritical CO2 process: Placing dye coated textile

material inside the supercritical ‘Dyeing vessel’ on a

supercritical fluid processing plant.

d. Adding the supercritical CO2 into the ‘Dyeing ves-

sel’. Exact operating conditions are optimized as per

the type of dye, auxiliary chemicals and textile used,

wherein the supercritical CO2 solubilizes the dye

molecules that were earlier coated on the surface

of the textile material and further diffuses the solu-

bilized dye molecules inside the surface, pores and

capillaries of the textile material;

e. Depressurizing the supercritical fluid dyeing vessel

to precipitate and entrap the dye material inside the

textile material.

f. Post-Treatment: Mild soap washing of the dyed &

finished textile with and stentering.

Innovative Elements of Patented Process from DSPL:

1. Novel / Inventive step: Pre-coating of textiles to

be dyed, with optimum quantity of dye & auxiliary

chemical molecules, per unit area of textiles to in-

crease surface area of solute and improve rate of sol-

ubilisation of dye & other molecules in supercritical

CO2. This also improves uniformity, reproducibility

of dyed shade, washing fastness and finishing effect.

2. Non-Obviousness: Use any pre-coating method such

as inkjet printing, Roller coating or similar process for

having a controlled pre-coating of optimum quantity

of dye molecules, auxiliary chemicals on the textile

material to achieve a single or multi-color / light or

dark shade dyeing of textiles with post processing

with SC CO2.

3. Industrial applicability: Patented improved technol-

ogy from DSPL eliminates major limitations of prior

art Supercritical dyeing processes available in the

market. Its innovative features make it very simple,](https://image.slidesharecdn.com/march-2022-digital-issue-231017111002-acc7f27c/85/Textile-Value-Chain-March-2022-29-320.jpg)

![51 TVC | MARCH 2022

T

here used to be days when one among very few

people around us wore a face/surgical mask in

day-to-day life, but now it’s a part of our life. As

per Wikipedia, the surgical mask is, “a face mask, in-

tended to be used by the health professionals during

the healthcare procedures. It is designed to stop infec-

tions in patient and treating personnel by catching the

bacteria sheds within the liquid droplets and aerosols

from wearer’s mouth and nose”. COVID-19 pandemic

has raised the urge to use the mask in day-to-day life.

So, let us know some basic knowledge about the most

used accessory the mask in this pandemic via this paper

[1][2].

Inthefinancialyear2019,theglobalmarketforthemask

was US$0.79 billion, and in the financial year 2020, it is

expected to have a global market of US$166.44 billion

which means within the year the business has grown

approximately 210 times (i.e., 21000%).

Careful veils are dispensable gadgets that cover the

mouth and nose during operations. They forestall the

spread of contamination among the unhealthy and sol-

id populace. Careful covers are commonly utilised in a

Aaditya Sushilkumar Patel(Textile Chemistry)*,

Akash Sambhaji Deshmukh( Fashion Technology)

D.K.T.E. Society’s Textile and Engineering Institute, Ichalkaranji, (MS) India.

Email*: aadityapatel174@gmail.com

wellbeing office (clinics, crisis offices, out-patient offic-

es, private consideration offices, crisis clinical benefits)

and home medical care conveyance. The Indian surgical

mask market could cost US$71.73 million by 2019 and

is expected to reach US$157.13 million by 2027, with

a CAGR of 10.3% registered need of mask in COVID-19

from 2020 to 2027. [3]

Generally, the mask is used to prevent the spread of the

diseases, face mask helps in preventing the spread of

infection, also an individual from contracting airborne

infectious germs. During coughing and sneezing an in-

fected person releases germ into the air that may in-

fect nearby healthy people. Masks are used as a part

of an infection control strategy that helps in eliminating

cross-contamination. This mask can also be used for the

prevention of air pollution-caused diseases.[6]

Protection of surgical mask (3 layers)

We need to know that how does mask help in being the

barrier between the infected person and the healthy

person. We all know that Corona virus is a super macro

(i.e., 100nm or 0.1um). Usually, the virus cannot exist

independently. Transmission of virus takes place from

Face Mask in the New Normal:

Material, Manufacturing & Testing

Abstract: The mask is the accessory which has become a part of con-

temporary life. It is the part of PPE (personal protection equipment) kit,

which is currently used against COVID-19. There are different types of

masks. Each mask has different application. This paper will be acknowl-

edging about masks and their functions. Different genre of mask is cloth

face mask, surgical mask, N95 respirator, P100 respirator/ gas mask, full

face respirator and KN95 respirator. The present study also elucidates the

certified test methods for various masks on the basis of evaluation char-

acteristic suggested by ASTM. Tests carried out on the mask are, Bacterial

filtration efficiency (BFE), Particular filtration efficiency (PFE), Fluid resist-

ance, Delta P and Flame speed tests.

Keywords: Mask, PPE Kit, COVID-19, N95, ASTM, etc.

Special Features](https://image.slidesharecdn.com/march-2022-digital-issue-231017111002-acc7f27c/85/Textile-Value-Chain-March-2022-51-320.jpg)

![52 TVC | MARCH 2022

close contact, secretion, and droplets while sneezing.

Droplet size is nearly 5 microns, i.e., a melt-blown layer

is sufficient to infiltrate the droplet viruses. This is be-

cause the droplets having the virus will be absorbed on

the surface of the melt-blown layer electro statically.

Thus, mask creates a basic barrier between the mouth

and nose and the virus. [3]

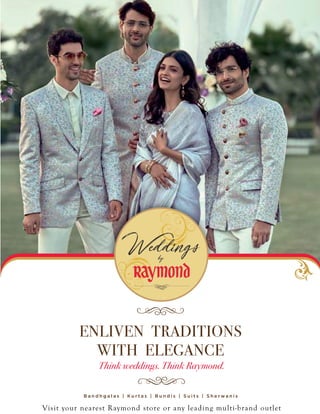

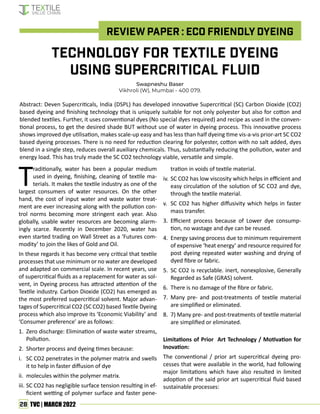

Figure 1. Distinct types of surgical mask. [7]

Usually, an authentic surgical mask is made up of 3-lay-

ers (Inner, Middle, and Outer). 2-layers masks are also

used, which are for hygiene and dust purposes but not

for viruses & bacteria.

Figure 2. Multiple layers of mask [4]

Outer layer – is a hydrophobic non-woven layer for wa-

ter repellent and blood repellent properties.

Middle layer – is a melt-blown layer. It is the highlight of

a surgical mask; it works as a filter to prevent entry or

exit of germ from the mask.

Inner layer – is a soft absorbent non-woven layer to ab-

sorb water, sweat and spit.

The 3-ply masks are effective as N-95 in protecting the

respiratory diseases like COVID-19.

Certified test methods for various masks

Certain test methods are described below which are

carried out to certify a mask as a surgical mask. These

test methods are used by the ASTM (American Society

for Testing and Materials) for the certification process.

The certification required is ASTM F2100.[5]

Bacterial filtration efficiency (BFE)

BFE measures the filtration capacity of the mask when

challenged with the bacteria-containing aerosol. Ac-

cording to ASTM F2101 guidelines, testing is carried out

with a droplet size of 3.0 microns containing Staphylo-

coccus aureus (avg. size 0.6 – 0.8 microns). The mask

with the 95% filtration is termed as the medical/surgical

masks. For moderate or high protection, the criteria are

98% filtration. [5]

Particular filtration efficiency (PFE)

It measures the filtration capacity of the mask for the

sub-micron particles, with the expectation that the vi-

ruses will be filtered in the same manner. Higher the fil-

tration %, better the mask. It is recommended to test

with a particle size of 0.1 microns. While comparing

make sure that the size of particles for testing must be

recommended. As per ASTM standards F2299 is accept-

ed for medical mask. [5]

Fluid resistance

This method is used for the mask used in the surgery. It

tests the ability of the outer layer to resist the transfer of

the fluid from the outer-layer to the inner-layer. This is

done because during surgery due to high blood pressure

blood of the human body, blood may get splashed over

the face. During this test synthetic blood is used with

pressure equivalent to human blood pressure. ASTM

1862 is assigned for fluid resistance test. [5]

Delta P (Pressure differential)

It measures the breathability of the mask and simulta-

neously the airflow resistance of the mask. Delta P is](https://image.slidesharecdn.com/march-2022-digital-issue-231017111002-acc7f27c/85/Textile-Value-Chain-March-2022-52-320.jpg)

![53 TVC | MARCH 2022

measured in mm H2O/cm2. Lower the value of Delta P

more is the breathability. ASTM value for the moderate

and the high barrier mask must be less than 5.0 and the

value must be less than 4.0 for low barrier mask. More-

over MIL-M369534C is the essential standard for testing

Delta-P. [5]

Flame speed

This test is done to measure the flame resistance of the

mask, as hospitals are occupied with oxygen, fuel, heat,

etc. The standard mask should resist flame for at least 3

seconds with a specific distance, and it is recognised as

16CFR part 1610.[5]

ISO certification

For skin sensitivity and cyto-toxic tests, to make sure

that harmful materials are not used in the mask, ISO

10993-5, 10 is denoted as standard for manufacturing

medical mask. [5]

Conclusion

The above article has an acknowledging view of masks

and their use in a recent situation. We get to know how

the construction of a mask is designed to protect from

viruses transferring airborne. The testing and certifica-

tion for a generic product of mask have brief in this arti-

cle. Secondly, the product ergonomics is also taken into

consideration. Finally, the market scenario where lately

there was not more market value as compared to a re-

cent market where the mask production is considered

as an essential required good. The mask manufacturers’

business today is 210 times more than in the previous

years.

References

1. https://en.m.wikipedia.org/wiki/Surgical_mask, cited

on 18th June 2021.

2. Jennifer L.W. Fink, RN, BSN, “Types of Masks and How

Effective They Are”, Review, Healthgrades, 2020.

3. Jiri Militky, Ondrej Novak, Dana Kremenakova, “A Re-

view of Impact of Textile Research on Protective Face

Masks”, Materials, 13 April 2021.

4. Medically reviewed by Deborah Weatherspoo, R.N.,

Written by Alex Bell, “Different types of face mask to use

during the COVID-19 pandemic”, Medical News Today,

2020.

5. Ming hui chua, weiren cheng, shermin simin goh,

“Face masks in the new covid-19 normal: material, test-

ing and perspectives”, Research a Science Partner Jour-

nal, 2020.

6. Medically reviewed by Deborah Weatherspoon, R.N.,

Written by Jill Seladi-Schulman, “Can Face Masks Pro-

tect You from the 2019 Coronavirus? What Types, When

and How to Use”, Healthline, 2020.

7. Explainer: N95? KF95? Which mask is the best at pro-

tecting against COVID-19, Written by Manijan maddi-

patla and Leroy Leo, on REUTERS, 19 January 2021.

The next edition of Techtextil North America will take

place in Atlanta from May 17nd to 19th. At Atlanta ACIM-

IT, the Association of Italian Textile Machinery Manufac-

turers, and Italian Trade Agency organize an Italian Pavil-

ion, where 17 Italian machinery manufacturers involved

in the production of machines for technical textiles will

show their innovative solutions.

ACIMIT members exhibiting in the Italian Pavilion are:

4M Plants, Aeris, Arioli, Computer House, Fadis, Flainox,

Guarneri Technology, Ima, Kairos Engineering, Mcs, Ram-

ina, Siltex, Stalam, Testa, Willy.

The US textile industry is one of the top in US manufac-

turing sector, with a sales volume of exceeding US$ 64

billion in 2020, with approximately 300,000 workers and

about 15,000 companies. The industry’s strength lies in

cotton, man-made fibers, and a wide variety of yarns and

fabrics, including those for apparel and industrial uses.

In 2021, the USA represented the third market for Italian

textile machinery exports, behind China and Turkey. In

2021 January-September period the value of Italian sales

to US market was 93 million Euros, an increase of 74%

compared to the same period of the previous year.

Visit us at ACIMIT/ITA Booth (2133, 2233 and 2333).

Italian Textile Machinery at Techtextil

North America 2022](https://image.slidesharecdn.com/march-2022-digital-issue-231017111002-acc7f27c/85/Textile-Value-Chain-March-2022-53-320.jpg)