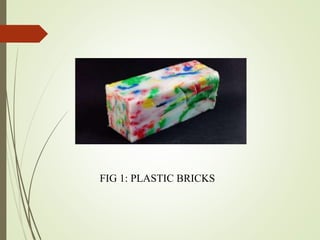

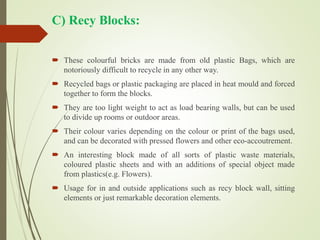

The document discusses various innovative building materials designed to reduce reliance on traditional resources such as concrete and wood. Examples include plastic bricks, bagasse particle boards, recy blocks, and self-repairing concrete, which not only enhance sustainability but also offer cost-effective and durable alternatives. It concludes by emphasizing the importance of adopting such materials to improve construction practices and minimize environmental impact.