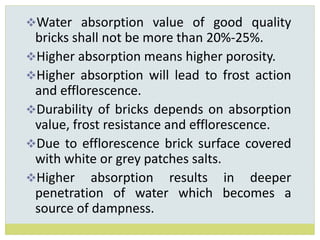

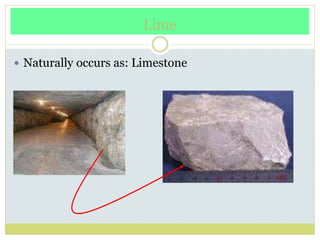

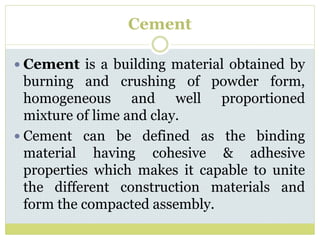

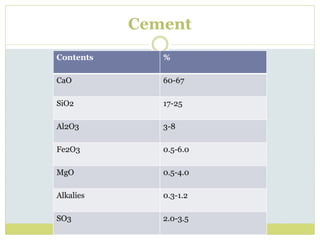

This document provides an overview of various construction materials used in civil engineering projects. It begins by discussing naturally available materials like stone, brick, lime, and timber. It then covers industrial materials like cement and metals. For each material, the document outlines the composition, requirements, types, properties and common uses. Stone is described in more detail, covering the different types of stone and their uses in hydraulic structures, retaining walls, and more. The document also provides a detailed breakdown of the production of bricks and their various classifications, as well as the properties and uses of lime, cement, and timber. It discusses the seasoning process for timber to reduce moisture content.