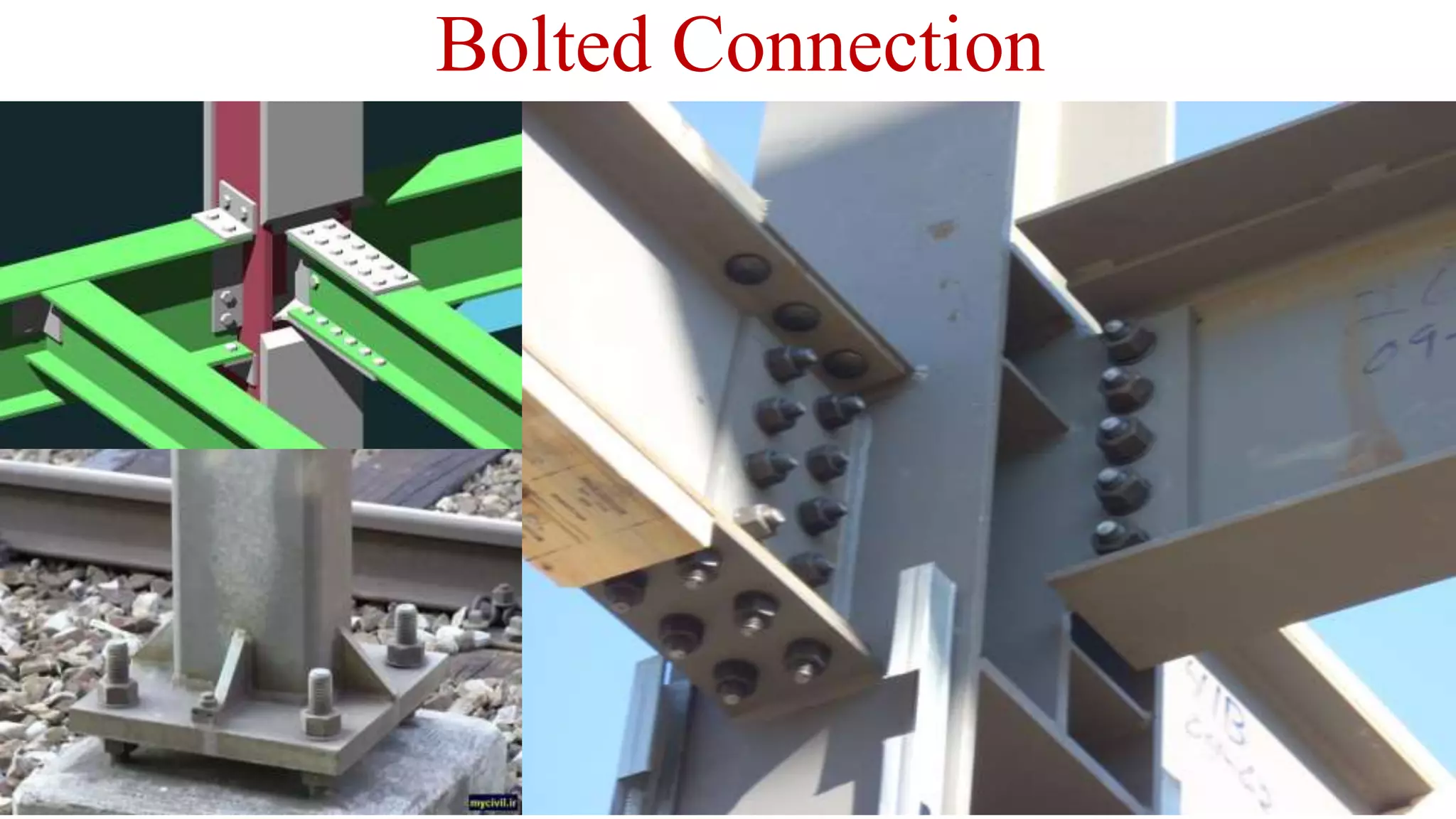

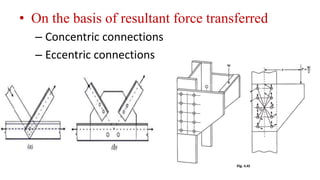

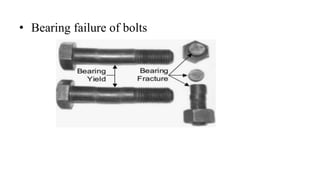

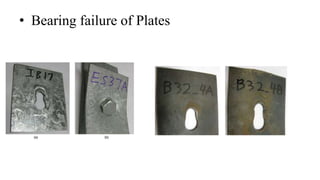

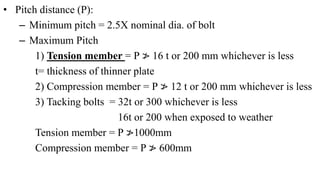

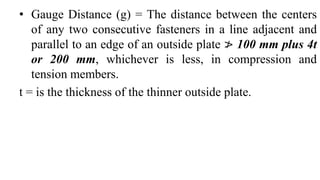

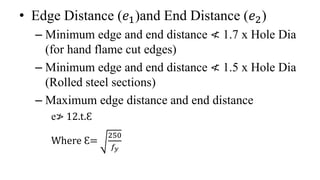

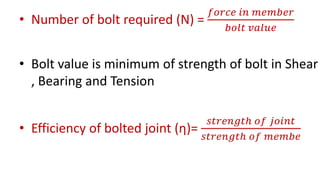

This document discusses bolted connections. It outlines advantages like quick fabrication and load transfer when bolts are tightened. Disadvantages include reduced strength under vibration if bolts loosen. Bolted connections are classified based on resultant force, bolt force type, and force transfer mechanism. Failure can occur via bolt shear, bearing, or tension, or plate bearing or tearing. Key terminology includes pitch (bolt spacing), gauge (row spacing), end and edge distances. Design considers bolt shear, bearing and tension strengths versus plate tensile strength.