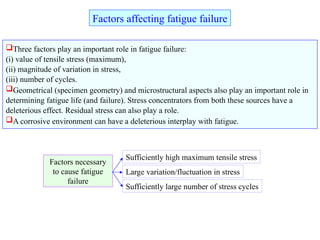

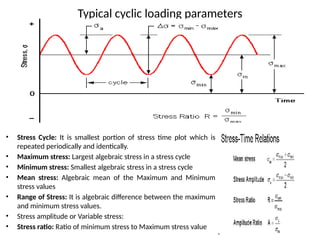

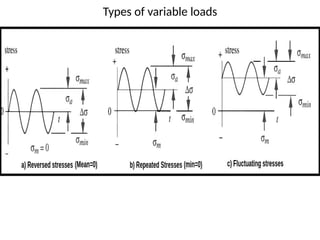

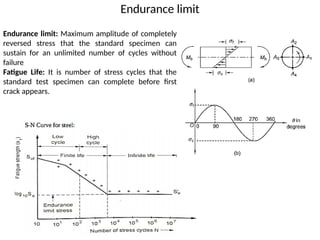

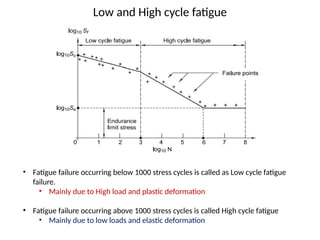

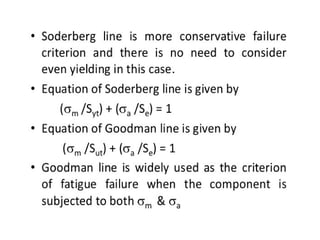

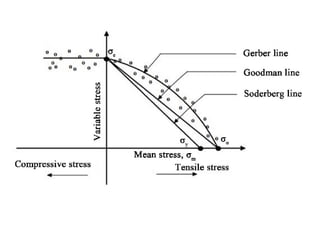

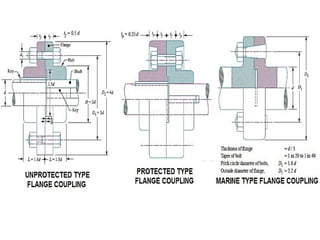

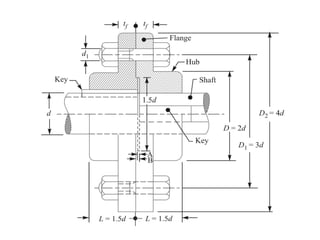

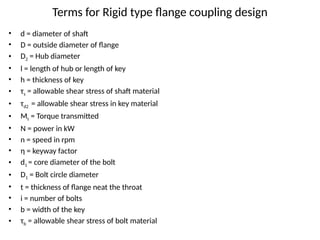

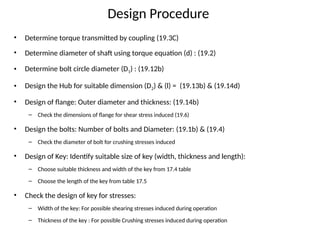

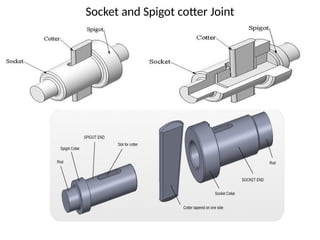

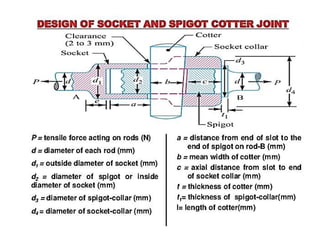

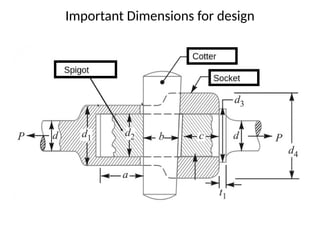

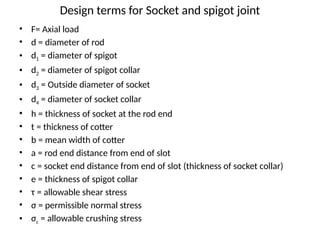

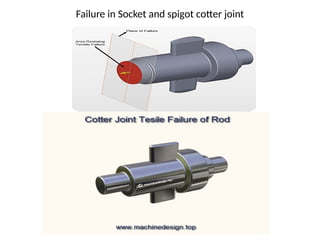

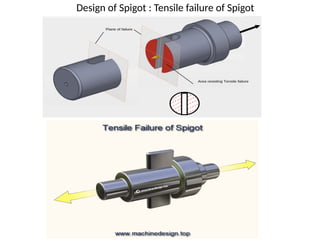

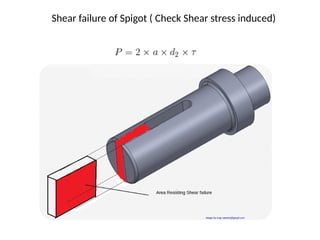

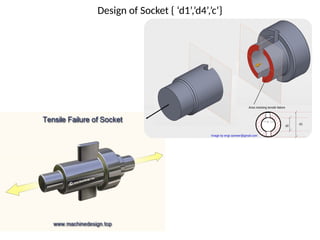

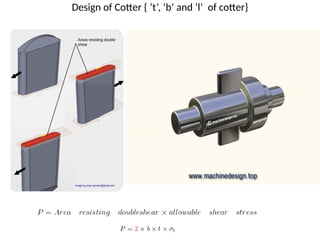

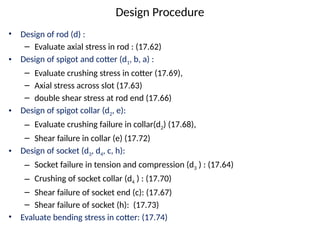

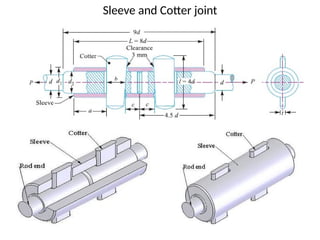

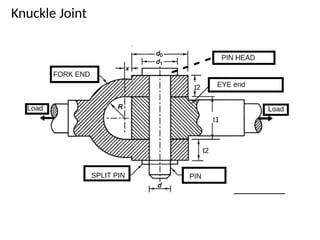

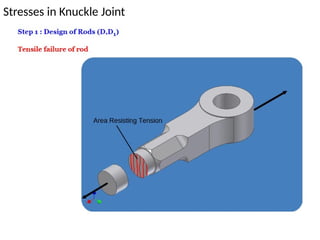

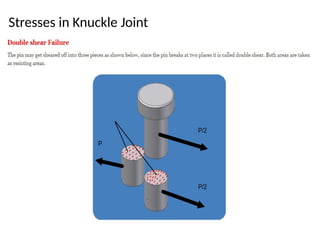

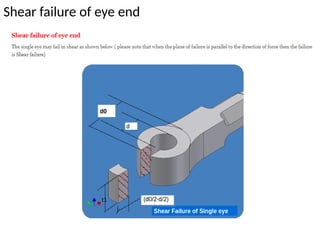

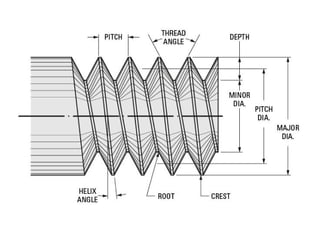

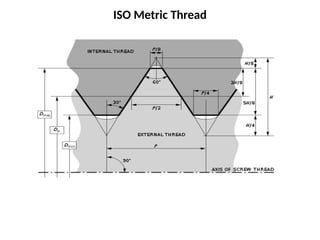

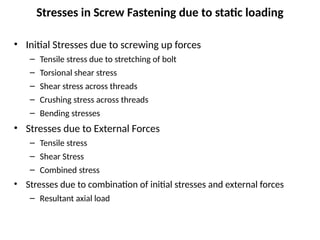

This document discusses fatigue strength in materials, detailing how repeated cyclic loading can lead to catastrophic failure due to accumulated damage from minor cracks. It covers factors influencing fatigue failure, including stress cycles, geometry, and environmental conditions, as well as the classification of coupling types and design procedures for joints and couplings. Specific design parameters and evaluation methods for joint failures, such as socket and spigot cotter joints, are outlined along with stresses in threaded fasteners.