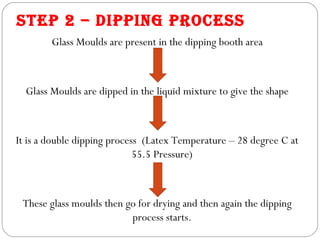

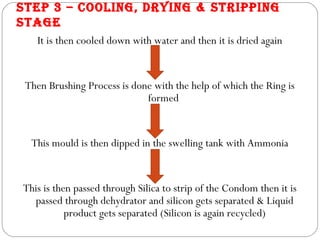

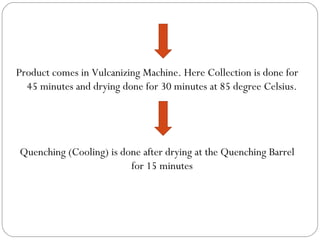

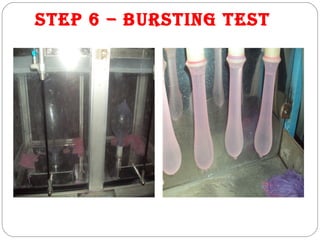

This document summarizes the 7-step process for manufacturing condoms at an HLL factory in Karnataka, India. The steps include: 1) mixing and grinding latex, 2) dipping molds in latex, 3) cooling, drying, and stripping condoms from molds, 4) quality control checks including visual inspection and pinhole testing, 5) more detailed pinhole testing, 6) bursting tests to ensure strength, and 7) lubrication and packaging prior to distribution. On average the factory produces 8 lakh (800,000) condoms per day through highly automated processes to ensure quality and safety.