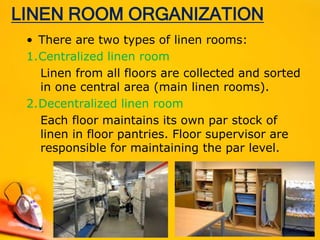

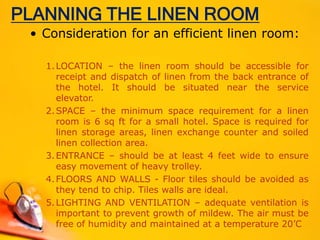

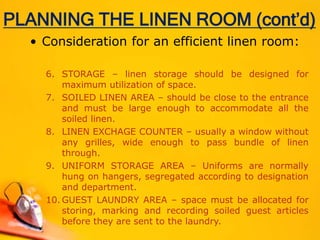

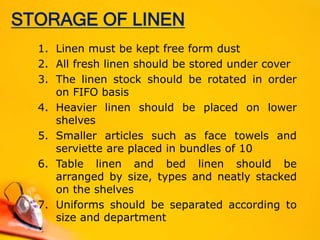

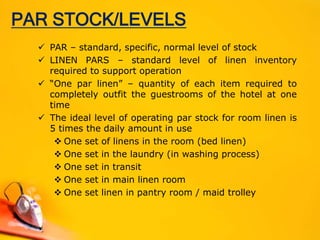

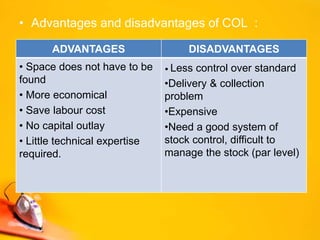

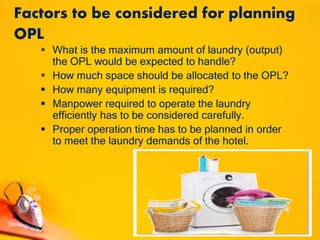

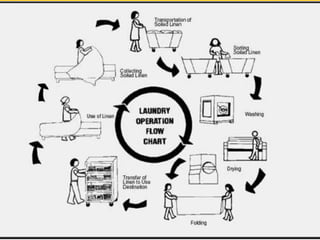

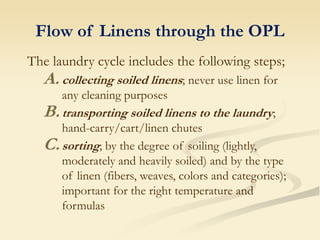

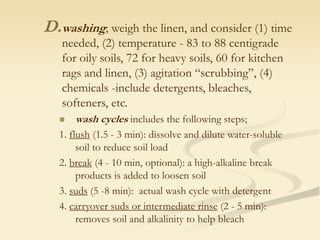

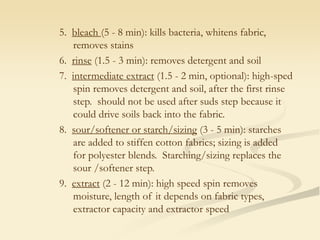

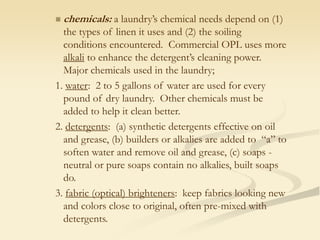

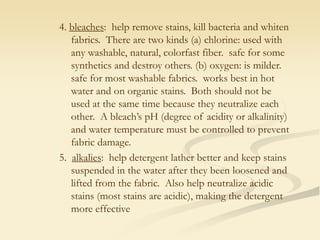

Chapter 7 discusses linen and laundry operations in hotels, emphasizing the importance of proper maintenance and organization of linen to uphold cleanliness standards. It outlines the roles of staff in the linen room, types of laundry operations (on-premise and contract-out), and key considerations for planning an efficient linen room. The chapter also details the laundry cycle, including the processes involved in washing, drying, and storing linens, along with common laundry problems and necessary equipment.