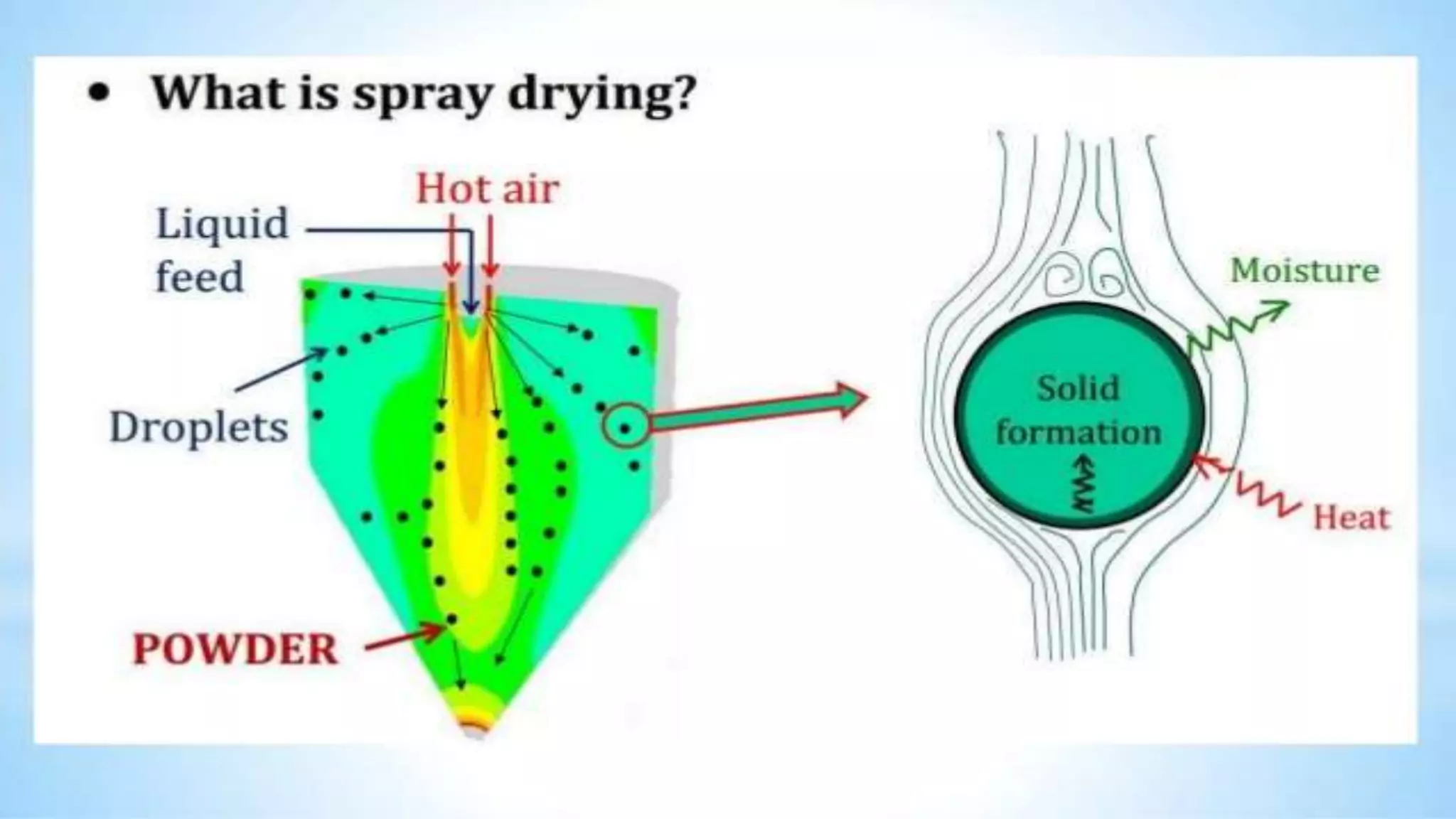

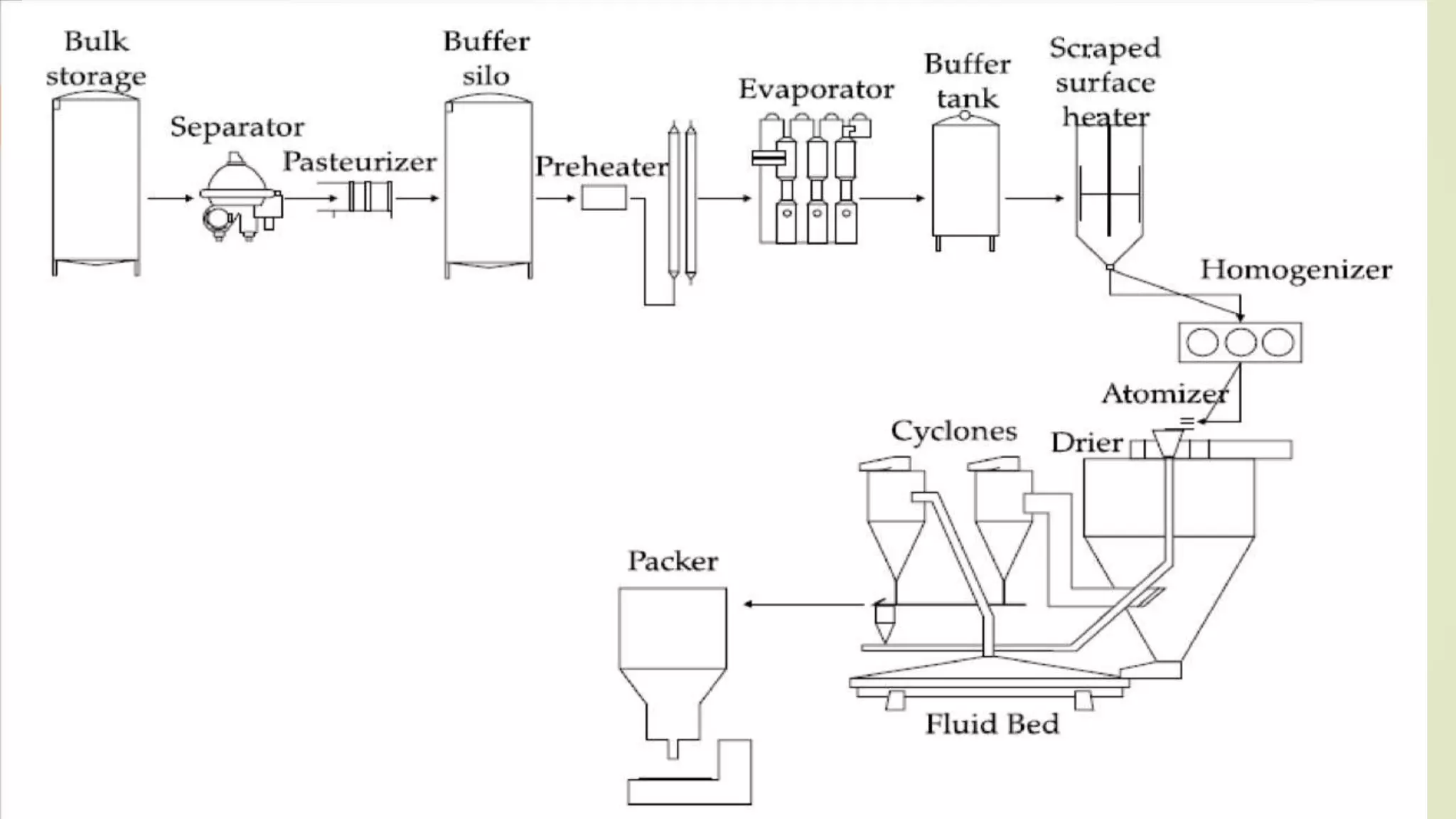

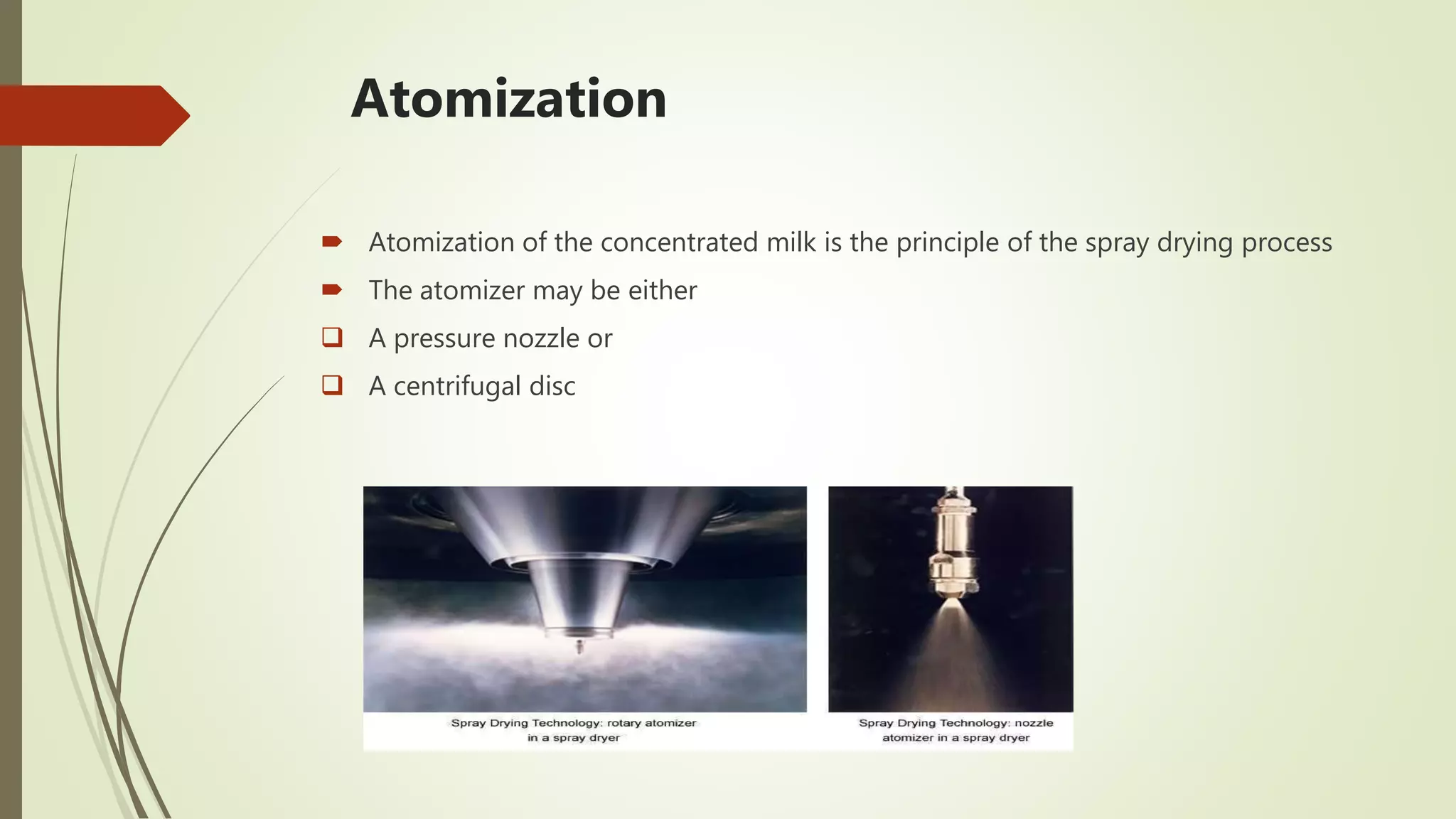

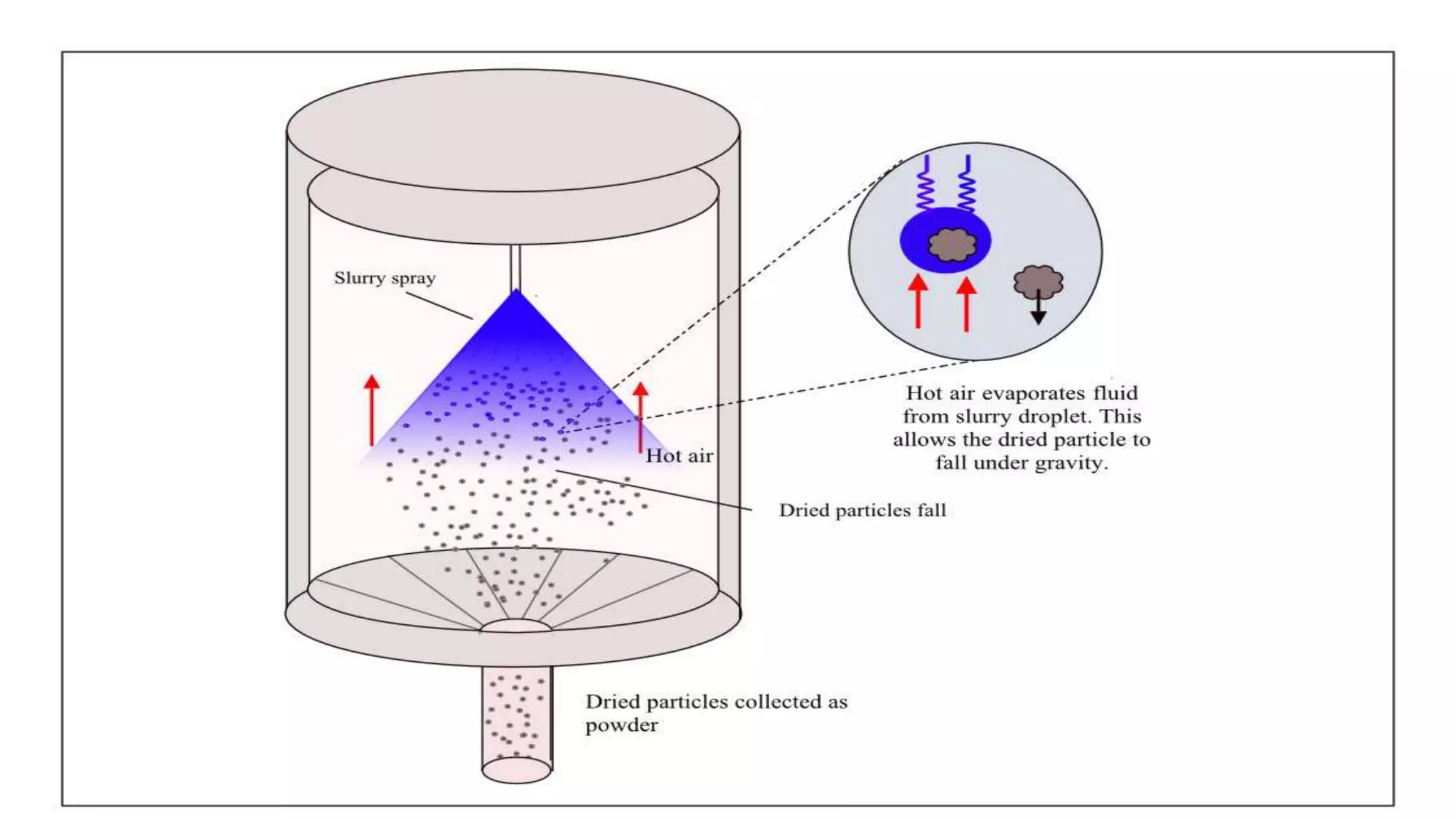

Milk is collected and tested before being stored in silos at the processing plant. It is then standardized, preheated to destroy bacteria and enzymes, and high temperature pasteurized. The milk is evaporated and concentrated to 40-50% before being homogenized and slightly heated. It is pumped at high pressure through an atomizer to create droplets that are dried in a chamber by hot air. The dried powder is separated and packaged in multi-wall bags for storage. Spray dried milk powder has applications in foods, pharmaceuticals, and various industries.