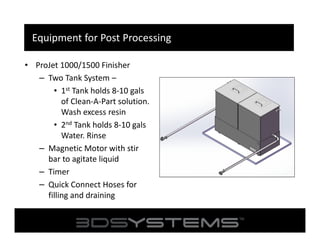

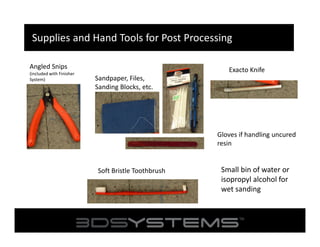

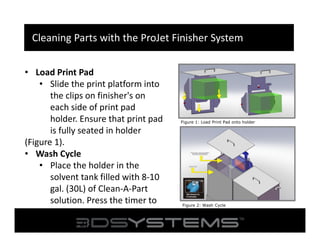

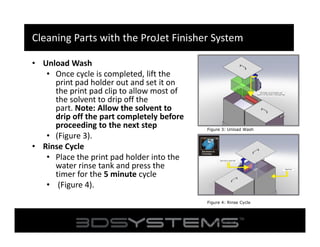

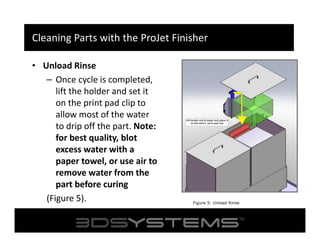

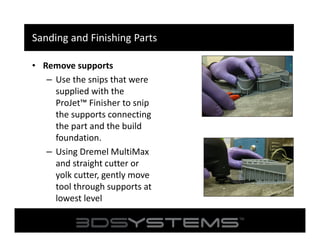

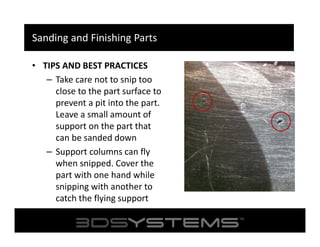

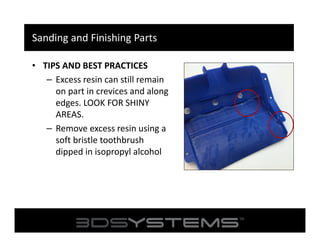

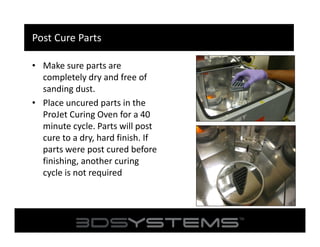

The document provides instructions for post-processing parts produced by the ProJet 1000/1500 3D printers. It describes using the ProJet Finisher system to clean parts with a washing cycle and rinse cycle. It also details removing supports, sanding parts, post-curing parts, and refreshing parts with oils. Proper post-processing is important for achieving high quality parts from the ProJet 1000/1500 printers.