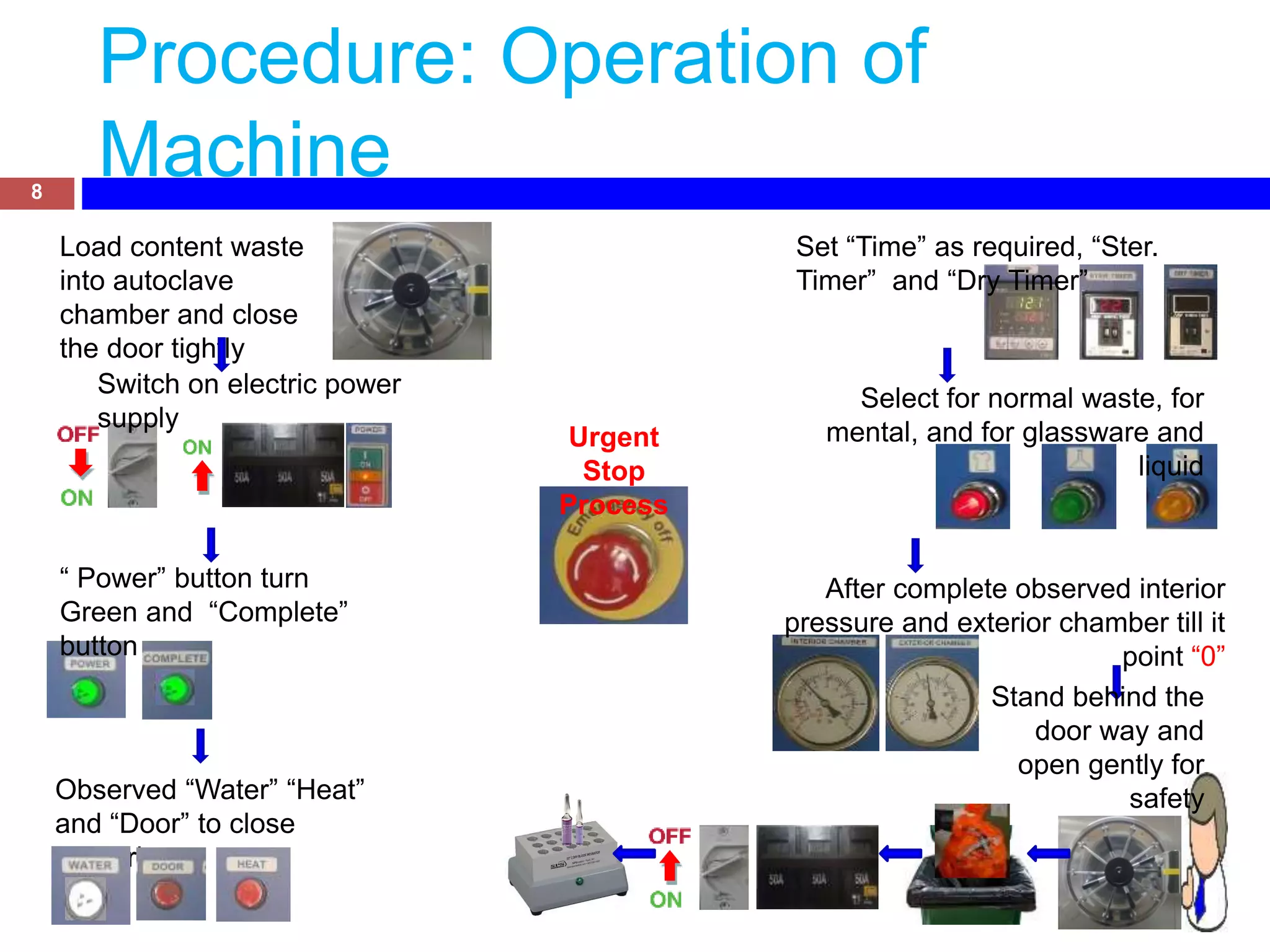

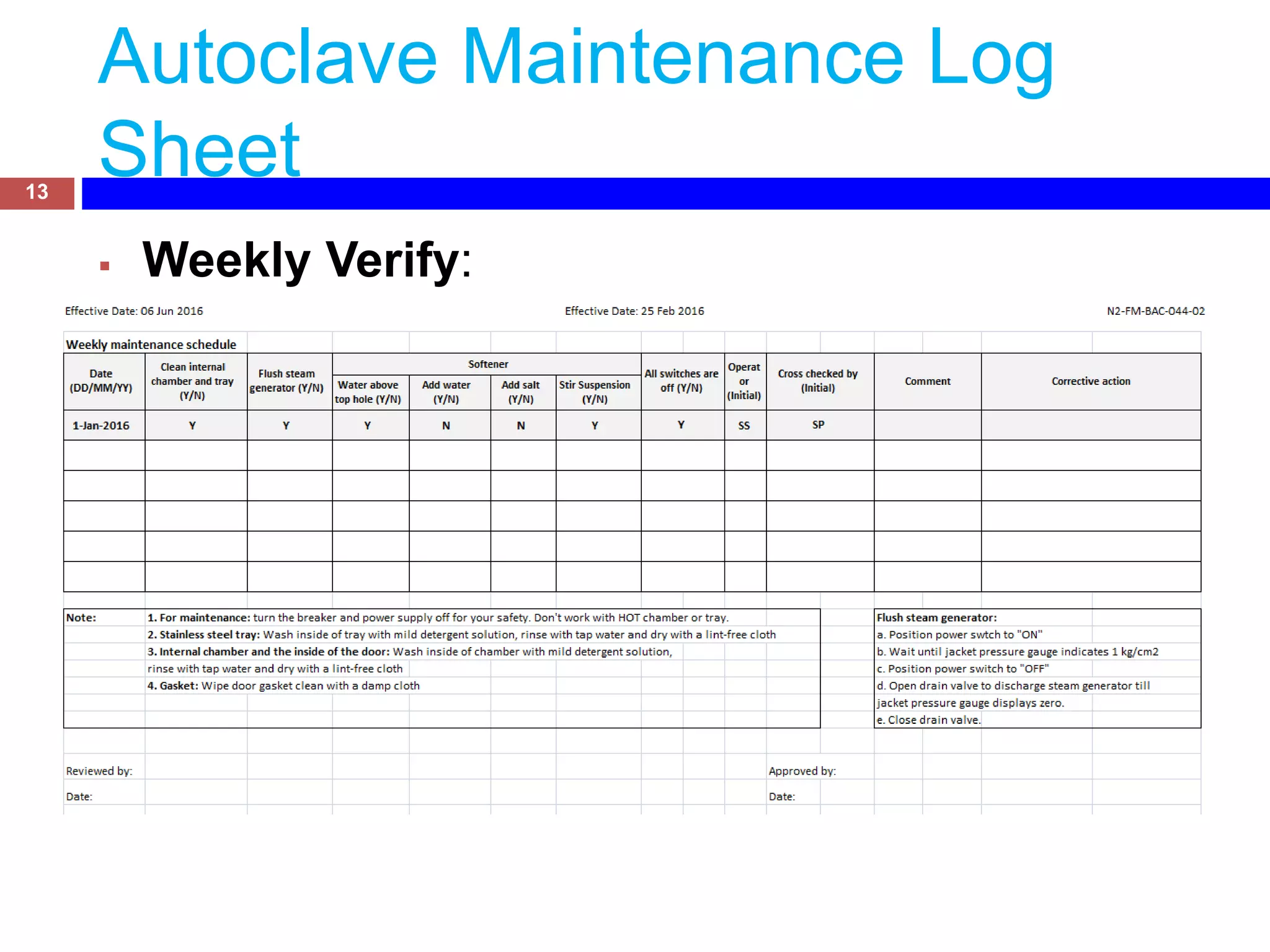

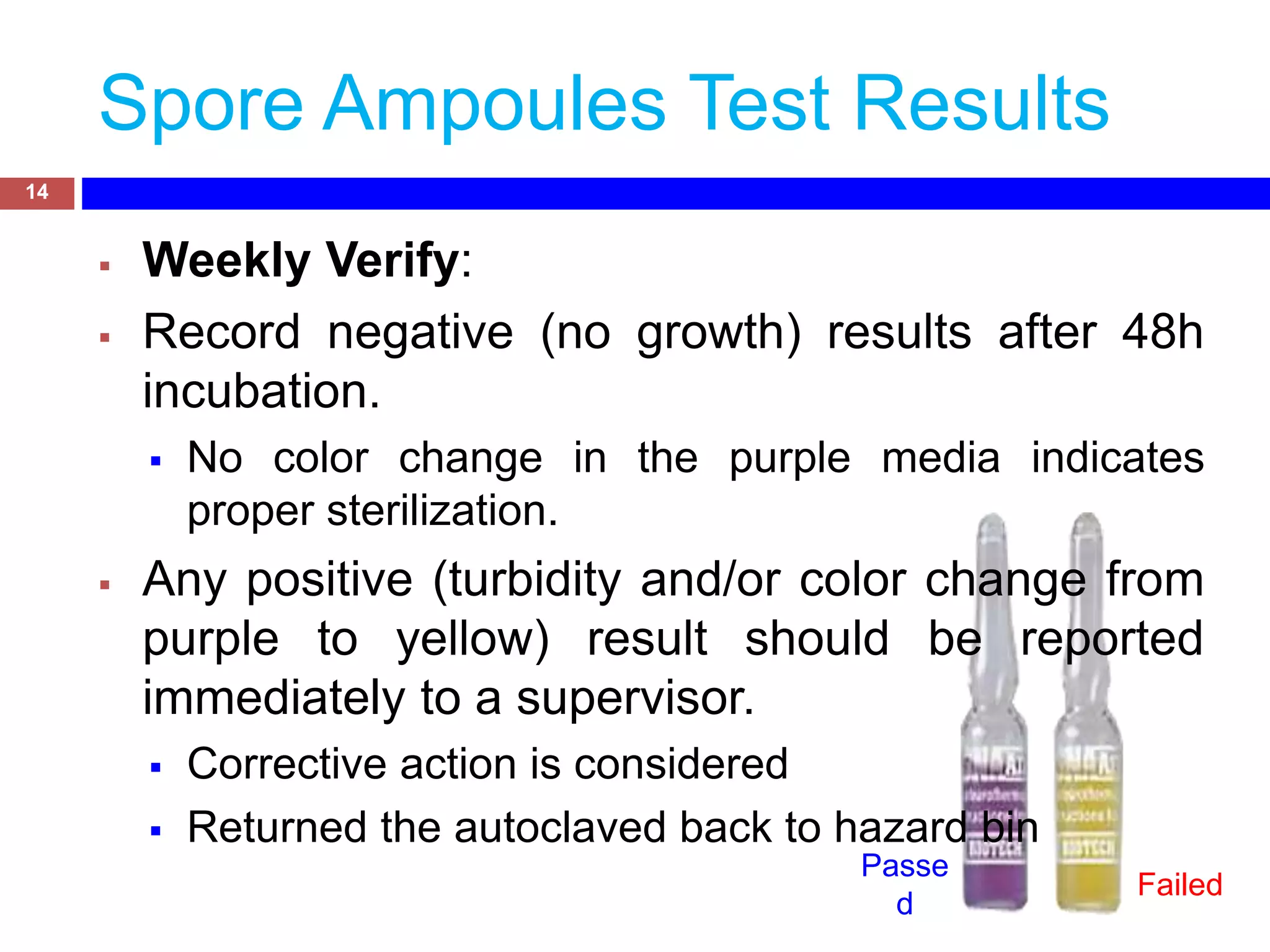

The document provides operating instructions and maintenance procedures for an autoclave. It describes how to prepare materials for sterilization, operate the autoclave including setting temperature and timers, and perform safety, quality control and maintenance checks. Key steps include using steam or chemical indicators to confirm sterilization, testing spore ampoules weekly for sterility, and documenting maintenance and test results in a log sheet. The autoclave sterilizes equipment and supplies using high pressure saturated steam to decontaminate items.