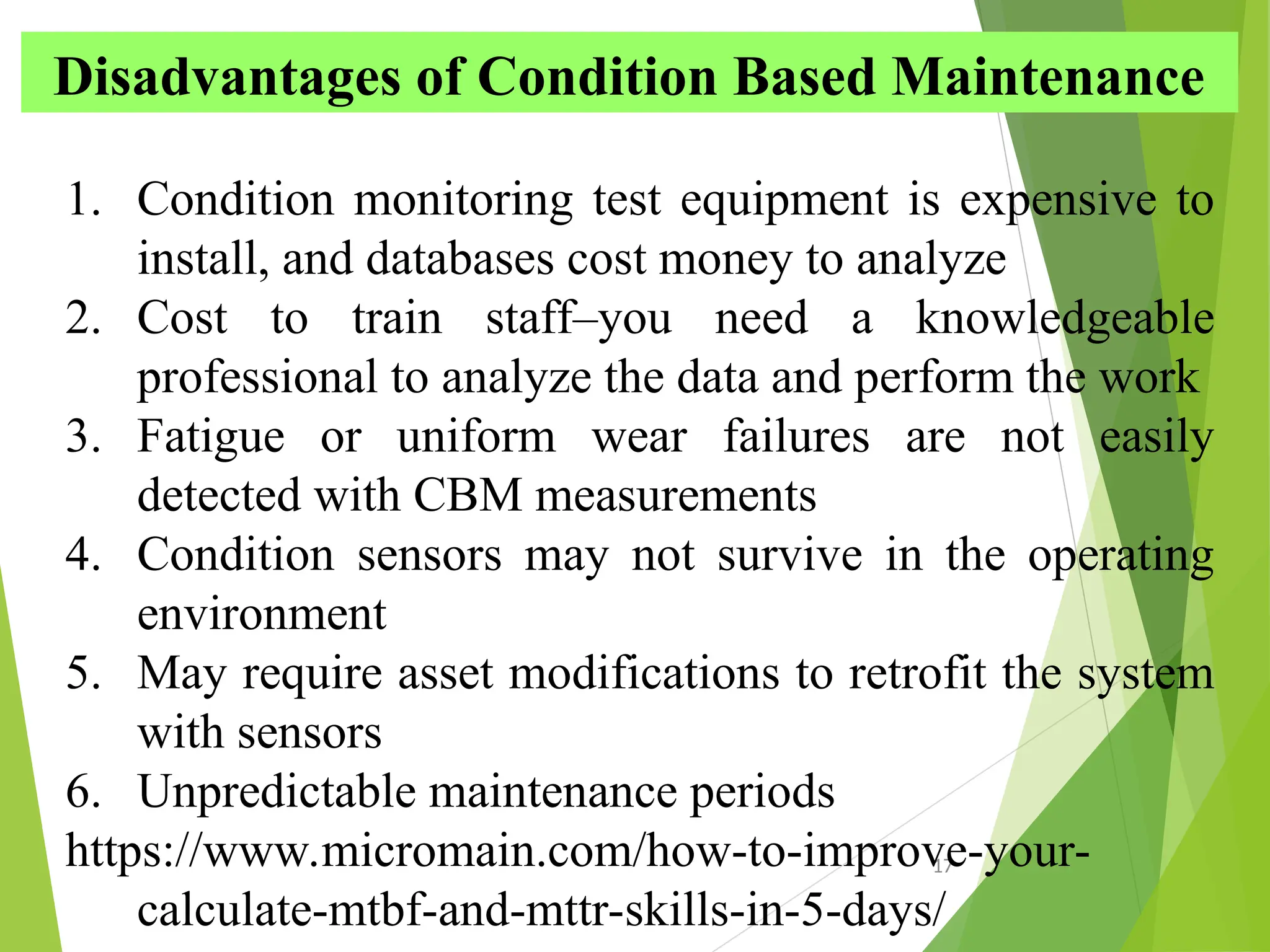

Condition-based maintenance (CBM) is a strategy that focuses on monitoring asset conditions to determine the timing of maintenance actions based on performance indicators. Successful implementation requires commitment, holistic participation from all stakeholders, and sustainability over time. Key benefits of CBM include improved safety, extended equipment life, reduced downtime, and enhanced product quality, while challenges include high costs of monitoring equipment and the need for skilled personnel.