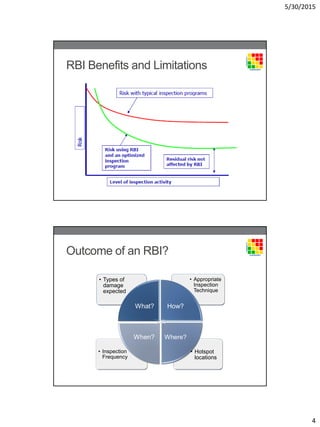

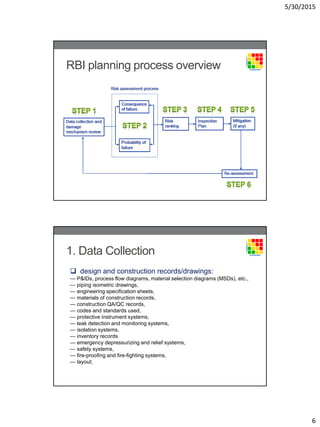

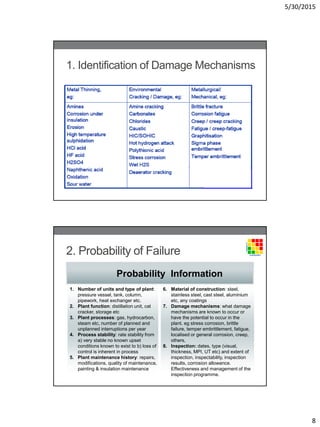

This document provides an overview of risk-based inspection (RBI) methodology. It defines RBI and compares it to other inspection methods. It outlines the key elements and benefits of an RBI program, including optimizing inspection costs, improving safety, and increasing availability. The document discusses international RBI standards and outlines the RBI planning process, including collecting equipment data, identifying damage mechanisms, analyzing risk, developing inspection plans, and reassessing over time. It also briefly introduces some RBI software options.